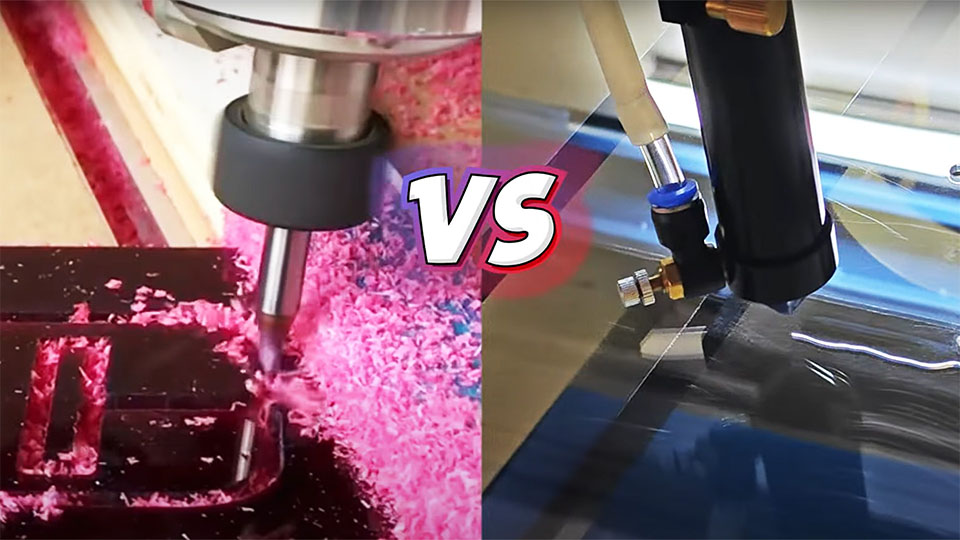

Uma kukhulunywa ngokusika nokuqoshwa kwe-acrylic, amarutha e-CNC nama-lasers avame ukuqhathaniswa. Iyiphi engcono? Iqiniso liwukuthi, ahlukene kodwa ayaphelelisana ngokudlala izindima ezihlukile emikhakheni eyahlukene. Uyini lo mehluko? Futhi kufanele ukhethe kanjani? Dlula esihlokweni bese usitshela impendulo yakho.

Isebenza Kanjani? CNC Acrylic Cutting

Irutha ye-CNC iyithuluzi lokusika lendabuko nelisetshenziswa kabanzi. Izinhlobonhlobo zamabhithi zingakwazi ukuphatha ukusika nokuqopha i-acrylic ekujuleni nokunemba okuhlukene. Amarutha e-CNC angasika amashidi e-acrylic aze afike ku-50mm obukhulu, alungele izinhlamvu zokukhangisa nezimpawu ze-3D. Kodwa-ke, i-CNC-cut acrylic idinga ukupholishwa kamuva. Njengoba omunye uchwepheshe we-CNC esho, 'Umzuzu owodwa wokusika, imizuzu eyisithupha ukupholisha.' Lokhu kudla isikhathi. Futhi, ukushintsha amabhithi nokusetha amapharamitha ahlukahlukene njenge-RPM, i-IPM, nezinga lokuphakelayo kukhulisa izindleko zokufunda nezabasebenzi. Ingxenye embi kakhulu uthuli nemfucumfucu yonke indawo, okungaba yingozi uma ihogelwa.

Ngokuphambene, i-laser cutting acrylic ihlanzekile futhi iphephile.

Isebenza Kanjani? I-Laser Cutting Acrylic

Ngaphandle kwendawo ehlanzekile yokusika nendawo yokusebenza ephephile, abasiki be-laser banikeza ukunemba okuphakeme kokusika nokuqoshwa ngogongolo oluncanyana njengo-0.3mm, i-CNC engeke lufaniswe nayo. Akukho ukupholisha noma ukushintsha kancane okudingekile, futhi ngokuhlanza okuncane, ukusika nge-laser kuthatha kuphela u-1/3 wesikhathi sokugaya i-CNC. Kodwa-ke, ukusika kwe-laser kunemikhawulo yokuqina. Ngokuvamile, sincoma ukusika i-acrylic ngaphakathi kwe-20mm ukuze uzuze ikhwalithi engcono kakhulu.

Ngakho-ke, ubani okufanele akhethe i-laser cutter? Futhi ubani okufanele akhethe i-CNC?

Ubani Okufanele Akhethe Irutha ye-CNC?

• I-Mechanics Geek

Uma unolwazi kubunjiniyela bokukhanda futhi ukwazi ukuphatha amapharamitha ayinkimbinkimbi afana ne-RPM, isilinganiso sokuphakelayo, imitshingo, nezimo zethiphu (i-cue animation yerutha ye-CNC ezungezwe amagama obuchwepheshe anokubukeka 'okuthoswe ingqondo'), irutha ye-CNC iyinketho enhle.

• Ngokusika Impahla Eminyene

Ilungele ukusika i-acrylic ewugqinsi, engaphezu kuka-20mm, iyenze ifanelekele izinhlamvu ze-3D noma amaphaneli aminyene e-aquarium.

• Okokuqoshwa Okujulile

Irutha ye-CNC ihamba phambili emisebenzini ejulile yokuqopha, njengokuqoshwa kwezitembu, ngenxa yokugaya kwayo okuqinile kwemishini.

Ubani Okufanele Akhethe I-Laser Router?

• Ngemisebenzi Eqondile

Ilungele imisebenzi edinga ukunemba okuphezulu. Kumabhodi okufa enziwe nge-acrylic, izingxenye zezokwelapha, amadeshibhodi emoto nawendiza, kanye ne-LGP, i-laser cutter ingathola ukunemba okungu-0.3mm.

• Kudingeka Ukungafihli Okuphezulu

Kumaphrojekthi e-acrylic acacile njengamabhokisi okukhanya, amaphaneli wokubonisa we-LED, namadeshibhodi, ama-laser aqinisekisa ukucaca okungenakuqhathaniswa nokuba sobala.

• Qalisa

Emabhizinisini agxile ezintweni ezincane, ezinenani eliphezulu njengobucwebe, izingcezu zobuciko, noma izindondo, isisiki se-laser sinikeza ubulula nokuguquguquka kokwenziwa ngokwezifiso, sidale imininingwane ecebile nenhle.

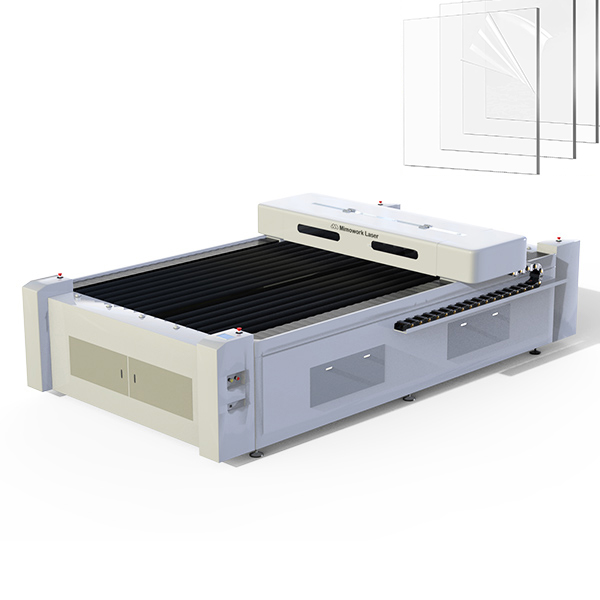

Kunemishini emibili evamile yokusika i-laser yakho: Imiqophi ye-laser encane ye-acrylic (yokusika nokuqopha) kanye nemishini yokusika ye-acrylic yeshidi elikhulu (engakwazi ukusika i-acrylic ewugqinsi ifike ku-20mm).

1. I-Acrylic Laser Cutter Encane & Engaraver

• Indawo yokusebenza (W * L): 1300mm * 900mm (51.2” * 35.4 ”)

• Amandla eLaser: 100W/150W/300W

• Umthombo weLaser: CO2 Glass Laser Tube noma CO2 RF Metal Laser Tube

• Isivinini sokusika esikhulu: 400mm/s

• Isivinini esikhulu sokuqopha: 2000mm/s

II-flatbed laser cutter 130ilungele ukusika nokuqopha izinto ezincane, njenge-keychain, imihlobiso. Kulula ukuyisebenzisa futhi ilungele ukuklama okuyinkimbinkimbi.

2. I-Acrylic Sheet Laser Cutter Enkulu

• Indawo yokusebenza (W * L): 1300mm * 2500mm (51” * 98.4”)

• Amandla eLaser: 150W/300W/450W

• Umthombo weLaser: CO2 Glass Laser Tube noma CO2 RF Metal Laser Tube

• Isivinini sokusika esikhulu: 600mm/s

• Ukunemba Kwesikhundla: ≤±0.05mm

Ii-flatbed laser cutter 130Lilungele ifomethi enkulu ye-acrylic sheet noma i-acrylic ewugqinsi. Kuhle ekuphatheni izimpawu zokukhangisa, umbukiso. Usayizi omkhulu wokusebenza, kodwa ukusikeka okuhlanzekile nokunembile.

Uma unezidingo ezikhethekile njengokuqoshwa ezintweni eziyisilinda, ama-sprues okusika, noma izingxenye zezimoto ezikhethekile,thintana nathiukuze uthole izeluleko ze-laser professional. Silapha ukuze sikusize!

Incazelo yevidiyo: I-CNC Router VS Laser Cutter

Kafushane, amarutha e-CNC angakwazi ukuphatha i-acrylic ewugqinsi, efika ku-50mm, futhi anikeze ukuguquguquka ngamabhithi ahlukene kodwa adinga ukupholisha ngemva kokusikwa futhi akhiqize uthuli. Abasiki be-laser bahlinzeka ngokuhlanza, ukusikeka okunembe kakhudlwana, asikho isidingo sokushintshwa kwamathuluzi, futhi akukho ukugqokwa kwamathuluzi. Kodwa, uma udinga ukusika i-acrylic ibe wugqinsi kuno-25mm, ama-laser ngeke akusize.

Ngakho-ke, i-CNC VS. I-Laser, iyiphi engcono ekukhiqizeni kwakho i-acrylic? Yabelana ngemininingwane yakho nathi!

1. Uyini umehluko phakathi kwe-CNC acrylic ne-laser cutting?

Amarutha e-CNC asebenzisa ithuluzi lokusika elijikelezayo ukuze asuse izinto ezibonakalayo, ezifanele i-acrylic ewugqinsi (kufika ku-50mm) kodwa ngokuvamile adinga ukupholishwa. Abasiki be-laser basebenzisa i-laser beam ukuze bancibilike noma bahwamulise impahla, banikeze ukunemba okuphezulu nemiphetho ehlanzekile ngaphandle kwesidingo sokupholisha, okungcono kakhulu nge-acrylic ezacile (kufika ku-20-25mm).

2. Ingabe ukusika i-laser kungcono kune-CNC?

Abasiki be-laser namarutha e-CNC bahamba phambili ezindaweni ezahlukene. Abasiki be-laser banikeza ukunemba okuphezulu nokusikeka okuhlanzekile, okulungele imiklamo eyinkimbinkimbi nemininingwane emihle. Amarutha e-CNC angakwazi ukuphatha izinto eziwugqinsi futhi angcono ekuqoshweni okujulile namaphrojekthi e-3D. Ukukhetha kwakho kuncike ezidingweni zakho ezithile.

3. Isho ukuthini i-CNC ekusikeni kwe-laser?

Ekusikeni ngelaser, i-CNC imele "Computer Numerical Control." Kubhekiselwa ekulawuleni okuzenzakalelayo komsiki we-laser kusetshenziswa ikhompuyutha, eqondisa ngokunembile ukunyakaza nokusebenza kwe-laser beam ukusika noma ukuqopha izinto.

4. Ishesha kangakanani i-CNC uma iqhathaniswa nelaser?

Amarutha e-CNC ngokuvamile asika izinto eziwugqinsi ngokushesha kunabasiki be-laser. Kodwa-ke, abasiki be-laser bayashesha ukuthola imiklamo enemininingwane neyinkimbinkimbi ezintweni ezizacile, njengoba bengadingi izinguquko zamathuluzi futhi banikeze ukusikeka okuhlanzekile ngokucubungula okuncane kwangemuva.

5. Kungani i-diode laser ingakwazi ukusika i-acrylic?

Amalaser e-Diode angadonsa kanzima nge-acrylic ngenxa yezinkinga ze-wavelength, ikakhulukazi ngezinto ezicacile noma ezinombala okhanyayo ezingakumumbi kahle ukukhanya kwe-laser. Uma uzama ukusika noma ukuqopha i-acrylic nge-laser diode, kungcono ukuhlola kuqala futhi ulungele ukwehluleka okungenzeka, njengoba ukuthola izilungiselelo ezifanele kungaba inselele. Ukuze uqoshwe, ungase uzame ukufafaza ungqimba lukapende noma ukufaka ifilimu endaweni ye-acrylic, kodwa jikelele, ngincoma ukusebenzisa i-CO2 laser ukuze uthole imiphumela engcono kakhulu.

Ngaphezu kwalokho, ama-laser e-diode angasika i-acrylic emnyama, e-opaque. Kodwa-ke, abakwazi ukusika noma ukuqopha i-acrylic ecacile ngoba impahla ayimunceli kahle i-laser beam. Ngokucacile, i-laser diode ekhanyayo eluhlaza okwesibhakabhaka ayikwazi ukusika noma iqophe i-acrylic eluhlaza okwesibhakabhaka ngesizathu esifanayo: umbala ofanayo uvimbela ukumuncwa okufanele.

6. Iyiphi i-laser engcono kakhulu yokusika i-acrylic?

I-laser engcono kakhulu yokusika i-acrylic yi-CO2 laser. Inikeza ukusikeka okuhlanzekile, okunembile futhi iyakwazi ukusika ubukhulu obuhlukahlukene be-acrylic ngempumelelo. Amalaser e-CO2 asebenza kahle kakhulu futhi afanele kokubili i-acrylic ecacile nenemibala, okuwenza abe yinketho ekhethwayo yokusika nokuqoshwa kwe-acrylic okuchwepheshile kanye nekhwalithi ephezulu.

Khetha umshini ofanele wokukhiqiza kwakho kwe-acrylic! Noma yimiphi imibuzo, xhumana nathi!

Isikhathi sokuthumela: Jul-27-2024