Uma umusha kubuchwepheshe be-laser futhi ucabangela ukuthenga umshini wokusika i-laser, kufanele kube nemibuzo eminingi ofuna ukuyibuza.

MimoWorkiyajabula ukwabelana nawe ngolwazi olwengeziwe mayelana nemishini ye-laser ye-CO2 futhi ngethemba, ungathola idivayisi ekufanele ngempela, kungakhathaliseki ukuthi ivela kithi noma omunye umhlinzeki we-laser.

Kulesi sihloko, sizonikeza ukubuka okufushane kokucushwa komshini endaweni evamile futhi senze ukuhlaziya okuqhathanisayo komkhakha ngamunye. Ngokuvamile, i-athikili izohlanganisa amaphuzu alandelayo:

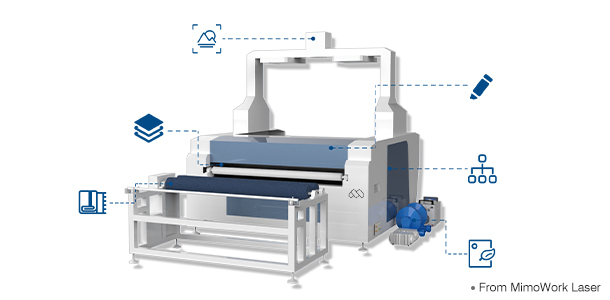

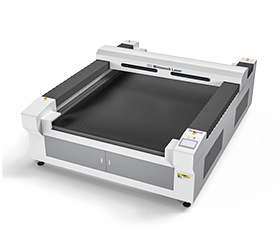

Imishini yomshini we-CO2 laser

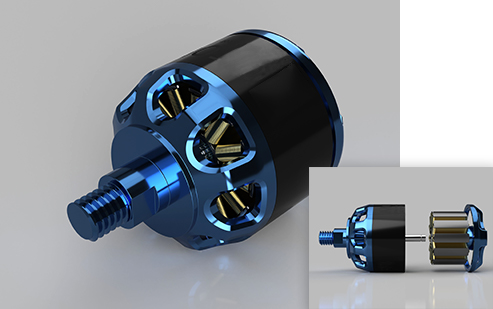

a. Brushless DC Motor, Servo Motor, Step Motor

I-Brushless DC (i-direct current) motor

I-Brushless DC motor ingasebenza nge-RPM ephezulu (izinguquko ngomzuzu). I-stator ye-DC motor inikeza inkambu kazibuthe ezungezayo eshayela i-armature ukuze ijikeleze. Kuzo zonke izinjini, i-brushless dc motor inganikeza amandla e-kinetic anamandla futhi ishayele ikhanda le-laser ukuthi lihambe ngesivinini esikhulu.Umshini wokuqopha we-laser we-MimoWork ongcono kakhulu we-CO2 ifakwe injini ye-brushless futhi ingafinyelela isivinini esiphezulu sokuqopha esingu-2000mm/s.I-brushless dc motor ayivamile ukubonakala emshinini wokusika we-CO2 laser. Lokhu kungenxa yokuthi ijubane lokusika ngempahla lilinganiselwe ubukhulu bezinto. Ngokuphambene nalokho, udinga kuphela amandla amancane ukuze uqophe ihluzo ezintweni zakho, I-brushless motor efakwe umqophi we-laser izokwazifinyeza isikhathi sakho sokuqopha ngokunemba okukhulu.

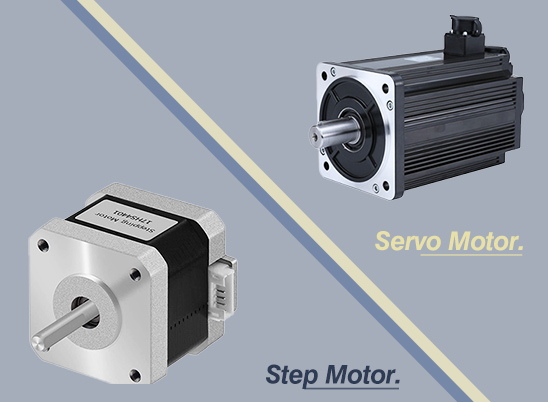

I-Servo motor & Isinyathelo motor

Uma ibhangqwe nethebula le-CO2 laser engraver, ama-servo motors anikeza i-torque ephakeme nokunemba, ikakhulukazi emisebenzini yobuchwepheshe efana nokusika indwangu yesihlungi noma amakhava okushisa. Nakuba zibiza kakhulu futhi zidinga izifaki khodi namabhokisi ogiya—okwenza ukusetha kube nzima nakakhulu—alungele izinhlelo zokusebenza ezifuna ngamandla. Sesikushilo lokho, uma wenza izipho ezilula zobuciko noma izimpawu, i-stepper motor etafuleni lakho lomqophi we-laser ngokuvamile yenza umsebenzi kahle.

Injini ngayinye inezinzuzo nezingozi zayo. Leyo evumelana nawe iyona engcono kakhulu kuwe.

Impela, iMimoWork ingahlinzeka ngeI-CO2 laser engraver kanye nomsiki ngezinhlobo ezintathu zenjiningokusekelwe kwimfuneko yakho kanye nesabelomali.

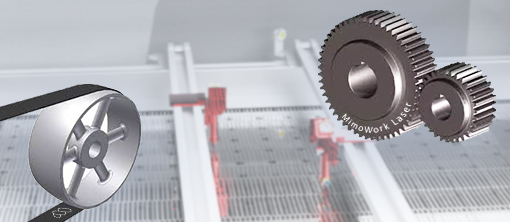

b. I-Belt Drive VS Gear Drive

Ibhande lokushayela lisebenzisa ibhande ukuze lixhumanise amasondo, kanti igiya lixhuma amagiya ngqo ngamazinyo ahlanganayo. Emishinini ye-laser, womabili amasistimu asiza ukuhambisa i-gantry futhi athinte ukuthi umshini ungaba nembe kangakanani.

Ake siqhathanise lezi ezimbili nethebula elilandelayo:

| I-Belt Drive | Gear Drive |

| Isici esiyinhloko Ama-Pulleys kanye nebhande | Isici esiyinhloko Amagiya |

| Kudingeka isikhala esengeziwe | Isikhala esincane esidingekayo, ngakho-ke umshini we-laser ungaklanywa ube mncane |

| Ukulahleka kwe-friction ephezulu, ngakho-ke ukudluliselwa kuphansi nokusebenza kahle okuncane | Ukulahleka kokungqubuzana okuphansi, ngakho-ke ukudluliselwa okuphezulu nokusebenza kahle okwengeziwe |

| Impilo elindelekile ephansi kunemishini yokushayela, imvamisa ishintsha njalo eminyakeni emi-3 | Iminyaka yokuphila inkulu kakhulu kunokushayela amabhande, ngokuvamile ishintsha njalo eminyakeni eyishumi |

| Idinga ukunakekelwa okwengeziwe, kodwa izindleko zokuyilungisa ishibhile futhi zilula | Idinga ukulungiswa okuncane, kodwa izindleko zokuyilungisa ziyathandeka futhi zinzima |

| Ukugcotshwa akudingeki | Idinga ukugcotshwa okuvamile |

| Kuthuleke kakhulu ekusebenzeni | Kunomsindo osebenzayo |

Zombili izinhlelo zokushayela igiya nebhande zivame ukuklanywa emshinini wokusika we-laser onezinzuzo nobubi. Ngamafuphi nje,uhlelo lokushayela ibhande lunenzuzo kakhulu kusayizi omncane, izinhlobo zemishini endizayo; ngenxa yokudluliselwa okuphezulu nokuqina,idrayivu yegiya ifaneleka kakhulu kumsiki we-laser enefomethi enkulu, ngokuvamile enomklamo we-hybrid optical.

c. Ithebula Lokusebenza Elinganyakazi VS Ithebula Lokusebenza Lokuthutha

Ukuze wenze kahle ukucutshungulwa kwe-laser, udinga okungaphezu kokuhlinzekwa nge-laser yekhwalithi ephezulu kanye nesistimu yokushayela evelele ukuze uhambise ikhanda le-laser, itafula elifanele lokusekela impahla liyadingeka. Ithebula elisebenzayo elenzelwe ukufanisa impahla noma uhlelo lokusebenza lisho ukuthi ungakwazi ukwandisa amandla omshini wakho we-laser.

Ngokuvamile, kunezigaba ezimbili zamapulatifomu asebenzayo: I-Stationary ne-Mobile.

(Ezinhlelo zokusebenza ezahlukahlukene, ungagcina ususebenzisa zonke izinhlobo zezinto, nomaimpahla yeshidi noma impahla ehlanganisiwe)

○Ithebula Lokusebenza Elinganyakaziilungele ukubeka izinto zeshidi njenge-acrylic, izinkuni, iphepha (amakhadibhodi).

• ithebula lokuhlubula ummese

• Itafula lekhekhe lezinyosi

○Ithebula Lokusebenza Le-Conveyorilungele ukubeka izinto zokugoqa njengendwangu, isikhumba, igwebu.

• itafula le-shuttle

• ithebula lokuthutha

Izinzuzo zomklamo ofanelekile wetafula lokusebenza

✔Ukukhishwa okuhle kakhulu kwe-cut emissions

✔Zinzisa okokusebenza, akukho kususwa okwenzekayo lapho usikwa

✔Kulula ukulayisha nokulayisha ama-workpieces

✔Isiqondiso sokugxila esiphezulu sibonga izindawo eziyisicaba

✔Ukunakekelwa okulula nokuhlanza

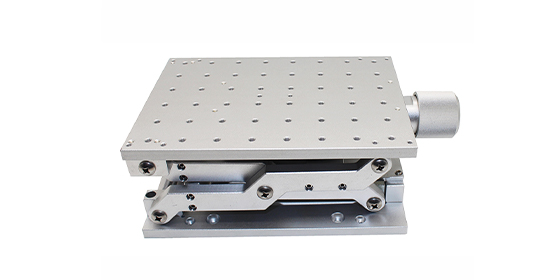

d. I-Automatic Lifting VS Manual Lifting Platform

Uma uqopha izinto eziqinile, njengei-acrylic (PMMA)futhiukhuni (MDF), izinto zokwakha ziyahlukahluka ngobukhulu. Ubude bokugxila obufanelekile bungakhulisa umphumela wokuqopha. Inkundla yokusebenza elungisekayo iyadingeka ukuze uthole indawo encane okugxilwe kuyo. Ngomshini wokuqopha we-laser we-CO2, amapulatifomu okuphakamisa okuzenzakalelayo kanye namapulatifomu okuphakamisa okwenziwa ngesandla kuvame ukuqhathaniswa. Uma ibhajethi yakho yanele, vakashela izinkundla zokuziphakamisa ezizenzakalelayo.Akukona nje ukuthuthukisa ukunemba kokusika nokuqopha, kungakongela amathani esikhathi nomzamo.

e. Upper, Side & Down Ventilation System

Isistimu yokungenisa umoya ephansi iwukukhetha okuvamile komshini we-laser CO2, kodwa i-MimoWork futhi inezinye izinhlobo zomklamo ukuze kuthuthukiswe isipiliyoni sokucubungula i-laser. Okweusayizi omkhulu laser cutting umshini, i-MimoWork izosebenzisa okuhlanganisiweuhlelo lokuqeda phezulu nangaphansiukukhulisa umphumela wokukhipha ngenkathi ugcina imiphumela yekhwalithi ephezulu yokusika i-laser. Kwabaningi bethuumshini wokumaka we-galvo, sizofaka iuhlelo lwe-ventilation ohlangothiniukuqeda intuthu. Yonke imininingwane yomshini kufanele iqondiswe kangcono ukuxazulula izinkinga zemboni ngayinye.

An uhlelo lokukhiphaikhiqizwa ngaphansi kwento eyenziwa ngomshini. Akukhiphi nje intuthu ekhiqizwe ukwelapha okushisayo kodwa futhi kuzinzisa okokusebenza, ikakhulukazi indwangu enesisindo esincane. Ingxenye yendawo yokucubungula embozwe into ecutshungulwayo iba nkulu, iba nkulu umphumela wokumunca kanye ne-vacuum ewumphumela yokumuncwa.

CO2 ingilazi laser amashubhu VS CO2 RF laser amashubhu

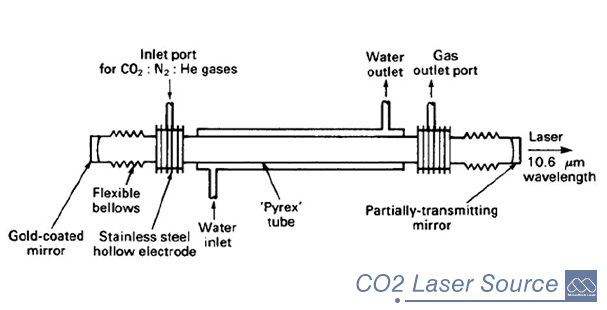

a. Umgomo wokuvusa i-CO2 laser

I-carbon dioxide laser yayingelinye lama-laser egesi okuqala okufanele athuthukiswe. Ngamashumi eminyaka okuthuthukiswa, lobu buchwepheshe buvuthwe kakhulu futhi banele izinhlelo zokusebenza eziningi. Ishubhu ye-laser ye-CO2 ijabulisa i-laser ngomgomo wokuthiukukhishwa okukhanyayofuthiiguqula amandla kagesi abe amandla okukhanya agxilile. Ngokufaka i-voltage ephezulu ku-carbon dioxide (i-laser medium esebenzayo) nenye igesi ngaphakathi kweshubhu le-laser, igesi ikhiqiza ukukhishwa okukhanyayo futhi ijabule ngokuqhubekayo esitsheni phakathi kwezibuko ezibukwayo lapho izibuko zitholakala ezinhlangothini ezimbili zomkhumbi ukuze zikhiqize i-laser.

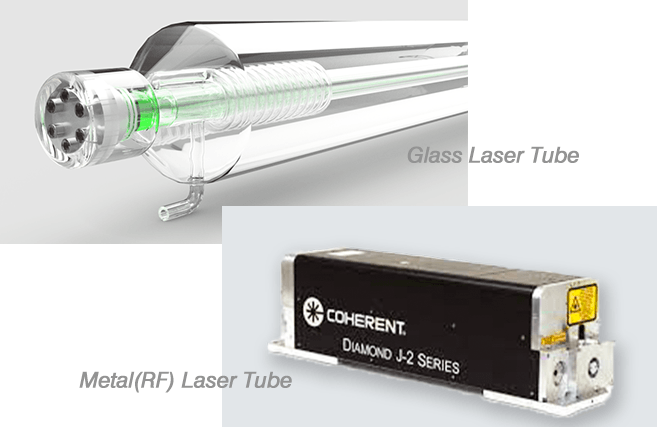

b. Umehluko we-CO2 glass laser tube & CO2 RF laser tube

Uma ufuna ukuqonda kabanzi ngomshini we-laser we-CO2, kufanele umbe imininingwane yomshini we-laser we-CO2.umthombo we-laser. Njengohlobo lwe-laser olufaneleka kakhulu ukucubungula izinto ezingezona ezensimbi, umthombo we-laser CO2 ungahlukaniswa ngobuchwepheshe obubili obuyinhloko:I-Glass Laser TubefuthiI-RF Metal Laser Tube.

(Kodwa-ke, i-laser yamandla aphezulu e-CO2 esheshayo ne-axial flow kancane kancane ayikho kububanzi bengxoxo yethu namuhla)

| Ingilazi (DC) Laser Tubes | Metal (RF) Laser Tubes | |

| Ubude bempilo | 2500-3500 amahora | 20,000 amahora |

| Ibhrendi | IsiShayina | Ukuhambisana |

| Indlela Yokupholisa | Ukupholisa Amanzi | Ukupholisa Amanzi |

| Iyashajwa kabusha | Cha, sebenzisa isikhathi esisodwa kuphela | Yebo |

| Iwaranti | 6 izinyanga | Izinyanga ezingu-12 |

Lawula Isistimu neSofthiwe

Isofthiwe yomshini wokusika we-laser we-CO2 isebenza njengobuchopho besistimu, isebenzisa uhlelo lwe-CNC ukuqondisa ukunyakaza kwe-laser nokulungisa amazinga amandla. Inika amandla ukukhiqizwa okuguquguqukayo ngokukuvumela ukuthi ushintshe imiklamo ngokushesha futhi uphathe izinto ezihlukene-nje ngokulungisa amandla e-laser nesivinini sokusika, azikho izinguquko zamathuluzi ezidingekayo.

Abaningi emakethe bazoqhathanisa ubuchwepheshe be-software yase-China kanye nobuchwepheshe besofthiwe yezinkampani ze-laser zaseYurophu naseMelika. Ngokumane usike futhi uqophe iphethini, ama-algorithms ama-software amaningi emakethe awahlukani kakhulu. Ngeminyaka eminingi kangaka yempendulo yedatha evela kwabakhiqizi abaningi, isoftware yethu inezici ezingezansi:

1. Kulula ukuyisebenzisa

2. Ukusebenza okuzinzile nokuphephile esikhathini eside

3. Hlaziya isikhathi sokukhiqiza kahle

4. Sekela i-DXF, i-AI, i-PLT namanye amafayela amaningi

5. Ngenisa amafayela okusika amaningi ngesikhathi esisodwa ngamathuba okuguqulwa

6. Hlela ngokuzenzakalelayo amaphethini okusika ngamakholomu nemigqa ngeI-Mimo-Nest

Ngaphandle kwesisekelo sesoftware ejwayelekile yokusika, iIsistimu Yokubona Umbonoingathuthukisa izinga le-automation ekukhiqizeni, inciphise abasebenzi futhi ithuthukise ukunemba kokusika. Ngamagama alula, Ikhamera ye-CCD noma Ikhamera ye-HD efakwe emshinini we-laser CO2 isebenza njengamehlo omuntu futhi iyala umshini we-laser ukuthi usike kuphi. Lobu buchwepheshe buvame ukusetshenziswa ezinhlelweni zokuphrinta zedijithali nezinkambu zokufekethisa, njengezingubo zezemidlalo ezidayi-sublimation, amafulegi angaphandle, ama-embroidery patches nokunye okuningi. Kunezinhlobo ezintathu zendlela yokuqaphela umbono iMimoWork enganikeza:

▮ Ukuqashelwa kweContour

Ukuphrinta kwedijithali kanye ne-sublimation kuyanda, ikakhulukazi emikhiqizweni efana nezingubo zemidlalo, amabhanela, nezinyembezi. Lezi zindwangu eziphrintiwe azikwazi ukusikwa ngokunembile ngesikele noma ama-blade endabuko. Yilapho izinhlelo ze-laser ezisekelwe embonweni zikhanya khona. Usebenzisa ikhamera enokulungiswa okuphakeme, umshini uthwebula iphethini futhi usike ngokuzenzakalelayo ngohlaka lwayo—akudingeki ifayela lokusika noma ukusika okwenziwa ngesandla. Lokhu akuthuthukisi ukunemba kuphela kodwa futhi kusheshisa ukukhiqizwa.

Umhlahlandlela Wokusebenza:

1. Yondla imikhiqizo enephethini >

2. Thatha isithombe sephethini >

3. Qala ukusika i-contour laser >

4. Qoqa okuqediwe >

▮ Iphoyinti Lokubhalisa Lokubhalisa

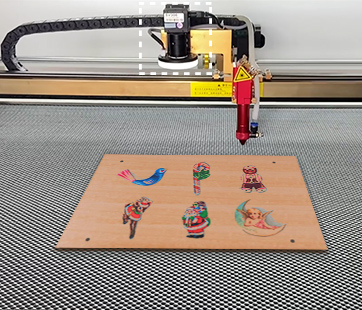

Ikhamera ye-CCDingabona futhi ithole iphethini ephrintiwe ebhodini lezinkuni ukusiza i-laser ngokusika okunembile. Izimpawu zokhuni, ama-plaque, imidwebo nesithombe sokhuni esenziwe ngokhuni oluphrintiwe singacutshungulwa kalula.

Isinyathelo 1.

>> Phrinta ngokuqondile iphethini yakho ebhodini lezinkuni

Isinyathelo sesi-2.

>> Ikhamera ye-CCD isiza i-laser ukusika umklamo wakho

Isinyathelo sesi-3.

>> Qoqa izingcezu zakho eziqediwe

▮ Ukufanisa Isifanekiso

Kwamanye amapheshana, amalebula, ama-foil aphrintiwe anosayizi ofanayo kanye nephethini, Uhlelo Lokubona Okufaniswayo Kwezifanekiso oluvela ku-MimoWork luzoba usizo olukhulu. Isistimu ye-laser ingasika ngokunembile iphethini encane ngokubona nokubeka isifanekiso esisethiwe okuyifayela lokusika lomklamo ukuze lifane nengxenye yesici samapeshi ahlukene. Noma iyiphi iphethini, ilogo, umbhalo noma enye ingxenye ebonakalayo ebonakalayo ingaba ingxenye yesici.

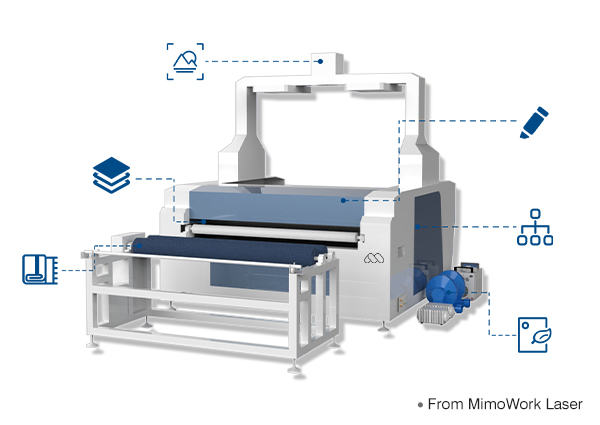

Izinketho ze-Laser

I-MimoWork inikeza izinketho eziningi ezengeziwe zabo bonke abasiki be-laser abayisisekelo ngokuhambisana nohlelo ngalunye. Enqubweni yokukhiqiza yansuku zonke, le miklamo eyenziwe ngezifiso emshinini we-laser ihlose ukwandisa ikhwalithi yomkhiqizo kanye nokuguquguquka ngokuvumelana nezimfuneko zemakethe. Isixhumanisi esibaluleke kakhulu ekuxhumaneni kwethu nathi kwasekuqaleni ukwazi isimo sakho sokukhiqiza, yimaphi amathuluzi asetshenziswayo njengamanje ekukhiqizeni, nokuthi yiziphi izinkinga ezihlangatshezwana nazo ekukhiqizeni. Ngakho-ke ake sethule izingxenye ezimbalwa ezivamile ozikhethela ezithandwayo.

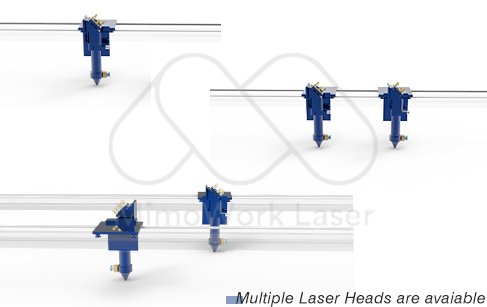

a. Amakhanda we-laser amaningi ongawakhetha

Ukwengeza amakhanda e-laser amaningi namashubhu emshinini owodwa kuyindlela elula nengabizi kakhulu yokuthuthukisa ukukhiqiza. Ilondoloza kokubili utshalomali kanye nendawo yaphansi uma kuqhathaniswa nokuthenga imishini eminingana ehlukene. Kodwa akuhlali kufanelana kahle kakhulu. Kuzodingeka ucabangele ubukhulu betafula lakho lokusebenza kanye namaphethini okusika. Kungakho sivame ukucela amakhasimende ukuthi abelane ngemiklamo yesampula ngaphambi kokufaka i-oda.

Imibuzo eyengeziwe mayelana nomshini we-laser noma ukulungiswa kwe-laser

Isikhathi sokuthumela: Oct-12-2021