Ungakwazi yini Ukusika i-Plywood nge-Laser?

umshini wokusika we-laser wePlywood

I-Plywood ingenye yezinkuni ezivamile ezisetshenziselwa ifenisha, izimpawu, imihlobiso, imikhumbi, amamodeli, njll. I-plywood iqukethe ama-veneers amaningi futhi ibonakala ngokulula kwayo nokuzinza. I-plywood isetshenziswa kakhulu futhi inokusebenza okuhle kakhulu, kodwa ungase udideke ne-laser cut plywood, ngenxa yeglue yayo phakathi kwe-veneers ye-plywood. Ingabe i-plywood ingasikwa nge-laser?

Ngokuvamile, i-laser ingakwazi ukusika i-plywood futhi umphumela wokusika uhlanzekile futhi ucwebile, kodwa udinga ukukhetha izinhlobo ezifanele ze-laser kanye nemingcele ye-laser efanele njengamandla, isivinini, nokusiza komoya. Futhi into eyodwa okudingeka uyiqaphele mayelana nezinhlobo ze-plywood. Kulesi sihloko, sizokwethula imishini efanelekile ye-laser cut plywood, indlela yokukhetha i-plywood, nendlela yokusika i-plywood nge-laser ukuze uthole umphumela omuhle kakhulu wokusika. Ngaphezu kwalokho, i-laser engraving plywood idumile ngokudala umbhalo ohlukile, amaphethini, namalogo wemikhiqizo ye-plywood efana namathegi wamagama, izipho, nezimpawu zomkhiqizo.

Silandele ukuze uhlole amaphrojekthi we-laser cut plywood athakazelisayo. Uma unesithakazelo komunye wemishini yokusika i-plywood laser, xoxa nathi ngezintandokazi zakho kanye nezidingo zakho.

Ungakwazi yini Ukusika i-Plywood nge-Laser?

Impela, i-laser cutting plywood iyindlela edumile nephumelelayo yokwenza imiklamo enembile neyinkimbinkimbi.

Nge-laser cutter efanele kanye ne-plywood efanelekile, ungafinyelela emaphethelweni ahlanzekile kanye nokusikeka okuningiliziwe, okwenza kube ukukhetha okuthandwayo kumaphrojekthi nemiklamo ehlukahlukene ye-plywood.

Ungakhetha kanjani i-Plywood ye-Laser Cutting & Engraving?

Manje siyazi ukuthi i-plywood ifanele ukusika i-laser, kodwa i-plywood ehlukene izokhiqiza imiphumela ehlukene yokusika, ngakho-ke kunezici ezithile okudingeka uzicabangele lapho ukhetha i-plywood ye-laser:

1. I-Plywood Resin:

Okuqukethwe kwe-resin ku-plywood kunomthelela kumphumela wokusika nokuqopha. Okuqukethwe kwe-resin ephakeme, kusho amamaki amnyama asele onqenqemeni lokhuni noma ngaphezulu. Ngakho-ke ngaphandle kokuthi unolwazi olucebile lokususa iphutha emishinini ye-laser nokusetha imingcele ye-laser, asincomi ukukhetha i-plywood enokuqukethwe okuphezulu kwe-resin.

2. I-Plywood Surface:

Lapho ukhetha i-plywood, cabangela umthunzi wayo, okusanhlamvu, nombala. Ukusika nokuqopha nge-laser kungashiya amamaki amnyama, ngakho-ke khetha isiphetho se-plywood esifana nezidingo zomkhiqizo wakho nesitayela. Isibonelo, uma uhlela ukubhala nge-laser umbhalo noma imikhonzo, qiniseka ukuthi okusanhlamvu ngeke kuphazamise izimpawu zokuqoshwa namaphethini.

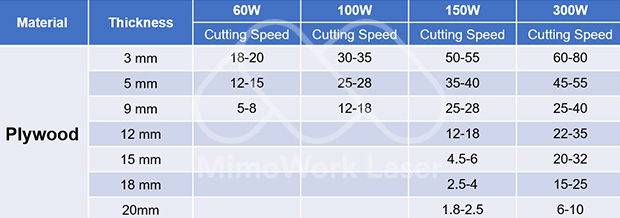

3. Ubukhulu bePlywood:

Ngokuvamile, ukuze kuqinisekiswe ikhwalithi yokusika, sincoma ukuthi ubukhulu bokhuni obungasikwa yi-laser bungaphakathi kuka-20mm. Ubukhulu obuhlukene beplywood, budinga amandla ahlukene we-laser. Lapho uthenga umshini wokusika we-laser we-plywood, thintana nomhlinzeki wakho we-laser ukuze uthole amandla afanele weshubhu le-laser namandla okusika.

4. Izinhlobo zePlywood:

Kunezinhlobo ze-plywood ezivamile ezifanele i-laser ongazibhekisela kuzo: i-bamboo plywood, i-brich plywood, i-hoop pine plywood, i-basswood plywood, ne-beech plywood.

Iyini i-Laser Cutting Plywood?

I-laser igxilisa amandla okushisa amakhulu endaweni encane ye-plywood, iyishisise kuze kube yilapho i-sublimation. Ngakho-ke kusele udoti nezicucu ezincane. Indawo yokusika nendawo ezungezile ihlanzekile.

Ngenxa yamandla aqinile, i-plywood izosikwa ngokuqondile lapho kudlula khona i-laser.

Izinhlobo Ezifanelekile Ze-Laser zokusika iPlywood

I-CO2 Laser ne-Diode Laser yizinhlobo ezimbili eziyinhloko ze-laser zokucubungula i-plywood.

1. I-CO2 laseriguquguquka futhi inamandla kangangokuthi ikwazi ukusika ngokushesha ku-plywood ewugqinsi, ishiye unqenqema lokusika oluhlanzekile nobushelelezi. Futhi nge-laser eqoshiwe plywood, i-CO2 laser inika amandla amaphethini enziwe ngokwezifiso, izimo namalogo. Ngakho-ke uma utshala umshini we-laser wokukhiqiza i-plywood, ukusika okusheshayo nokuqopha, umshini we-CO2 laser ufanelekile.

2. I-Diode laserayinawo amandla okusika i-plywood ngenxa yamandla ayo aphansi. Kodwa ilungele ukuqoshwa nokumaka endaweni ye-plywood. Ngokwezifiso futhi kuyavumelana nezimo.

I-Laser cutting plywood iyashesha, ikakhulukazi i-CO2 laser. Ngokuzenzakalela okuphezulu okufana ne-auto-focus, ithebula lokusika i-laser eliziphakamisayo, isofthiwe yokusika i-laser yedijithali, nokuningi, inqubo yokusika i-laser ye-plywood inomsebenzi omncane kanye nekhwalithi ephakeme yokusika.

I-Laser cutting plywood ihlanganisa ukusebenzisa i-laser enamandla kakhulu ukusika izinto ngokunembile. I-laser beam iqondiswe ku-plywood, i-sublimating impahla eceleni komugqa osikiwe futhi ikhiqize unqenqema olubushelelezi.

I-Laser isebenziseka ngezindlela eziningi ukusika nokuqopha imiklamo eyenziwe ngezifiso njengemihlobiso kaKhisimusi, amathegi ezipho, imisebenzi yezandla namamodeli.

Sisebenzise ucezu lweplywood ukwenza ezinyeLaser Cut Christmas imihlobiso, yinhle futhi iyinkimbinkimbi. Unentshisekelo kulokho, bheka ividiyo.

◆Ukuvumelana nezimo

Ama-Lasers angasika izinhlobonhlobo zamajamo namaphethini, okuvumela imiklamo yokudala neyinkimbinkimbi.

◆ Ukunemba Okuphezulu

Abasiki be-Laser bangafinyelela ukusikeka okunemininingwane emangalisayo nokunembile ku-plywood. Ungakwazi ukuklama futhi udale imiklamo eyinkimbinkimbi futhi eyinkimbinkimbi njengamaphethini angenalutho, i-laser cutter izoyenza ngenxa yemishayo yayo ye-laser emincane kakhulu.

◆I-Smooth Edge

I-laser beam ikhiqiza imiphetho ehlanzekile futhi ebushelelezi ngaphandle kwesidingo sokuqedela okwengeziwe.

◆Isebenza kahle kakhulu

Ukusika i-laser kuvame ukushesha kunezindlela zokusika zendabuko, okwandisa umkhiqizo.

◆Akukho Ukugqokwa Okungokomzimba

Ngokungafani nama-saw blades, i-laser ayixhumani ne-plywood ngokomzimba, okusho ukuthi akukho ukuguga nokudilika ethuluzini lokusika.

◆Ukusetshenziswa Okukhulu Okubalulekile

Ukunemba kwe-laser cutting kunciphisa udoti wezinto ezibonakalayo, kukwenze ukonga kakhulu.

1. Amamodeli Ezakhiwo:I-laser beam enembile kanye nokusika kwe-laser okuguquguqukayo kuletha amamodeli e-laser cut plywood ayinkimbinkimbi nanemininingwane, kumamodeli ezakhiwo kanye nezibonelo.

2. Izimpawu:Umshini wokusika we-laser we-plywood unamandla ukuthi unganqamula i-plywood ewugqinsi ngenkathi unomphetho wokusika ohlanzekile nobushelelezi. Izimpawu ze-laser cut plywood zilungele ukudala izimpawu zangokwezifiso ezinemiklamo eyinkimbinkimbi kanye nezinhlamvu.

3. Ifenisha:Ifenisha ye-laser cut plywood iletha ukuguquguquka okwengeziwe komklami wefenisha kanye nomuntu othanda ukuzilibazisa. Ngokunemba okuphezulu, i-laser cutting plywood ingakha ihinge yokuphila enhle (ebuye ibizwe ngokuthiizinkuni eziguquguqukayo), ukuthuthukisa ukubukeka nokuhlukile kwefenisha nomsebenzi wobuciko.

4. Imihlobiso Nemisebenzi Yezandla:Ukukhiqiza izinto zokuhlobisa njengobuciko bodonga, imihlobiso, nokuhlobisa kwasekhaya.

Ngaphandle kwalokho, i-laser cutting plywood idumile phakathilaser ukusika izinkuni nezimo, i-laser cutting wood puzzle, i-laser cutting wood lightbox, i-laser cutting artwork.

Thola i-laser cutter, khulula ubuhlakani bakho, yenza imikhiqizo yakho ye-plywood!

Noma yimiphi Imibono mayelana ne-Laser Cutting Plywood, Siyakwamukela Engxoxweni Nathi!

I-CO2 Laser iwumthombo we-laser ofaneleka kakhulu wokusika amabhodi e-plywood, ngokulandelayo, sizokwethula umshini wokusika we-CO2 ovamile nowaziwayo we-CO2 weplywood.

Ezinye Izinto Okufanele Uzicabangele

Lapho ukhetha umshini wokusika we-laser weplywood, izici ezimbalwa okufanele zicatshangelwe ukuze uqinisekise ukuthi uthola imiphumela engcono kakhulu yamaphrojekthi akho:

1. Usayizi Womshini(ifomethi yokusebenza):

Usayizi womshini unquma usayizi omkhulu wamashidi we-plywood namaphethini ongawasika. Uma udala imihlobiso emincane, imisebenzi yezandla, noma umsebenzi wobuciko wokuzilibazisa, indawo yokusebenza ye1300mm * 900mmkufanelekile. Kumaphrojekthi amakhulu afana nezimpawu noma ifenisha, umshini omkhulu wokusika we-laser onendawo yokusebenza1300mm * 2500mm kuhle.

2. Amandla e-Laser Tube:

Amandla eshubhu le-laser anquma amandla e-laser beam kanye nobukhulu beplywood ongayisika. Ishubhu ye-laser engu-150W ijwayelekile futhi ihlangabezana nezidingo eziningi zokusika amapulangwe. Ukuze uthole i-plywood ewugqinsi efika ku-20mm, ungase udinge ishubhu lelaser elingu-300W noma i-450W. Uma udinga ukusika i-plywood ibe mkhulu kuno-30mm, irutha ye-CNC ingase ifaneleke kakhulu kune-laser cutter.

Ulwazi oluhlobene ne-Laser:Ungayinweba kanjani impilo yesevisi ye-laser tube >

3. Ithebula lokusika i-Laser:

Ukusika izinto zokhuni ezifana ne-plywood, MDF, noma ukhuni oluqinile, kunconywa ithebula lokusika i-laser strip. Leli thebula liqukethe izinsimbi eziningi ze-aluminium ezisekela okokusebenza ngenkathi kugcinwa ukuthintana okuncane, okuqinisekisa indawo ehlanzekile kanye nonqenqema olusikiwe. Ukuze uthole i-plywood ewugqinsi, ungase futhi ucabangele ukusebenzisa ithebula elisebenzayo lephini.Ulwazi olwengeziwe mayelana nethebula lokusika le-laser >

4. Ukusika Ngempumelelo:

Linganisa izidingo zakho zokukhiqiza ze-plywood, njengesivuno sansuku zonke ofuna ukusifinyelela, bese uxoxa ngazo nochwepheshe we-laser onolwazi. Siklame amakhanda e-laser amaningi noma amandla omshini aphezulu ukuze ahlangabezane nezinhloso zakho zokukhiqiza. Okunye okusha kumathebula okusika i-laser, njengetafula lokusika le-laser eliziphakamisayo, ithebula lokushintshisana, namadivayisi ajikelezayo, kungathuthukisa kakhulu ukusika nokuqoshwa kwe-plywood. Ukwengeza, okunye ukucushwa okufana nama-servo motors namagiya kanye namadivayisi okudlulisa ama-rack kungaba nomthelela wokusika ukusebenza kahle. Ukubonisana nomhlinzeki wakho we-laser kuzokusiza ukuthi uthole ukucushwa kwe-laser okuphelele kwezidingo zakho.

Awunawo Umbono Wokukhetha Umshini We-Laser? Khuluma Nongcweti Wethu we-Laser!

Umshini Wokusika wePlywood Laser odumile

• Indawo yokusebenza: 1300mm * 900mm (51.2” * 35.4 ”)

• Amandla eLaser: 100W/150W/300W

• Isivinini sokusika esikhulu: 400mm/s

• Isivinini esikhulu sokuqopha: 2000mm/s

• Isistimu Yokulawula Imishini: Isinyathelo Sokulawula Ibhande Lezimoto

• Indawo yokusebenza: 1300mm * 2500mm (51” * 98.4”)

• Amandla eLaser: 150W/300W/450W

• Isivinini sokusika esikhulu: 600mm/s

• Ukunemba Kwesikhundla: ≤±0.05mm

• Isistimu Yokulawula Imishini: I-Ball Screw ne-Servo Motor Drive

FAQ of Laser Cutting Plywood

1. Iyiphi i-plywood ewugqinsi engasikwa yi-laser?

Siyazi ukuthi i-CO2 laser iwuhlobo lwe-laser olufaneleka kakhulu lokusika i-plywood. Ubukhulu bokusika esiphakamisa ukuthi bungu-20mm, obunganelisa umphumela omuhle wokusika kanye nesivinini sokusika. Sihlole ubukhulu obuhlukahlukene bokhuni lokusika i-laser futhi senza ividiyo ezoboniswa. Bheka lento.

2. Ungakuthola kanjani ukugxila okulungile kwe-laser cutting plywood?

Ukuze ulungise ubude bokugxila bokusika nge-laser, i-MimoWork yaklama idivayisi egxile ngokuzenzakalela kanye netafula lokusika i-laser eliziphakamisayo, ukuze ikusize uthole ubude obufanele bokugxila bezinto okufanele zisikwe.

Ngaphandle kwalokho, senze isifundo sevidiyo isinyathelo ngesinyathelo siyala ukuthi singanquma kanjani okugxilwe kuzo. Bheka lento.

3. I-laser idinga amandla angakanani ukusika i-plywood?

Mangakanani amandla e-laser owadingayo kuncike kubukhulu beplywood ozoyisika. I-150W ingamandla e-laser ajwayelekile okusika amapulangwe amaningi ukusuka ku-3mm ukujiya kuya ku-20mm ukujiya. Udinga nje ukulungisa iphesenti lamandla ocezwini lwe-scrap, ukuze uthole imingcele yokusika efanele.

Siphakamisa ukuthi usebenzise umshini we-laser ungabi ngaphezu kuka-80% -90% wamandla amakhulu e-laser, ukuze kwelule ubude bempilo yeshubhu le-laser.

Funda kabanzi mayelana nePlywood yokusika i-Laser noma enye izinkuni

Izindaba Ezihlobene

Uphayini, Ukhuni Olumisiwe, I-Beech, I-Cherry, I-Coniferous Wood, i-Mahogany, i-Multiplex, i-Natural Wood, i-Oak, i-Obeche, i-Teak, i-Walnut nokunye.

Cishe zonke izinkuni zingasikwa nge-laser futhi umphumela wokhuni wokusika we-laser muhle kakhulu.

Kodwa uma ukhuni lwakho oluzosikwa lunamathela efilimini enobuthi noma upende, ukuphepha kuyadingeka ngenkathi usika i-laser.

Uma ungaqiniseki,buzangochwepheshe be-laser iyona engcono kakhulu.

Uma kukhulunywa ngokusika nokuqoshwa kwe-acrylic, amarutha e-CNC nama-lasers avame ukuqhathaniswa.

Iyiphi engcono?

Iqiniso liwukuthi, ahlukene kodwa ayaphelelisana ngokudlala izindima ezihlukile emikhakheni eyahlukene.

Uyini lo mehluko? Futhi kufanele ukhethe kanjani? Dlula esihlokweni bese usitshela impendulo yakho.

Ingabe ubuzama ukuthola indlela yokudala iphazili yangokwezifiso? Lapho kudingeka ukunemba okuphezulu kakhulu nokunemba, abasiki be-laser cishe njalo kuyisinqumo esingcono kakhulu.

Lena inqubo yokusika impahla nge-laser beam, njengoba negama liphakamisa. Lokhu kungenziwa ukuze kuncishiswe okubalulekile noma ukusiza ekukusikeni kube amafomu ayinkimbinkimbi okungaba nzima ukuthi izivivinyo ezengeziwe zendabuko ziphathwe. Ngaphandle kokusika, abasiki be-laser bangase futhi bafake amadizayini e-raster noma bagcizelele izingcezu zokusebenza ngokushisisa indawo yokusebenza kanye nokubhoboza ungqimba olungaphezulu lwento ethile ukuze balungise ukubukeka lapho umsebenzi we-raster uqedwe khona.

Noma yimiphi imibuzo mayelana ne-Laser Cut Plywood?

Kugcine ukubuyekezwa: Okthoba 27, 2025

Isikhathi sokuthumela: Aug-08-2024