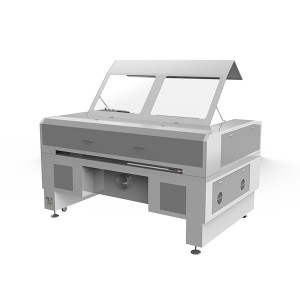

I-Plywood Laser Cutter

▶ Umshini wokusika we-Plywood laser, umshini wokuqopha we-plywood laser

Idatha Yezobuchwepheshe

| Indawo yokusebenza (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Isoftware | Isoftware engaxhunyiwe ku-inthanethi |

| Laser Amandla | 100W/150W/300W |

| Umthombo we-Laser | I-CO2 Glass Laser Tube noma i-CO2 RF Metal Laser Tube |

| IMechanical Control System | Isinyathelo Motor Belt Control |

| Ithebula Lokusebenza | I-Honey Comb Working Table noma I-Knife Strip Working Table |

| Isivinini esikhulu | 1~400mm/s |

| Isivinini Sokusheshisa | 1000~4000mm/s2 |

| Usayizi Wephakheji | 2050mm * 1650mm * 1270mm (80.7'' * 64.9'' * 50.0'') |

| Isisindo | 620kg |

Ithebula Lokusebenza elenziwe ngokwezifiso

Amathebula okusebenza enziwe ngokwezifiso anosayizi abahlukene ayatholakala ukuze avumelane nezidingo kusukela kwezobuciko obubucayi kuya ekucutshungulweni kwefenisha enkulu.

Ukusebenza okuningi emshinini owodwa

Idizayini Yokungena Okubili

Ukusika kwe-laser nokuqoshwa kwesakhiwo esikhulu sezinkuni ze-MDF kungenziwa kalula ngenxa yomklamo wokungena wezindlela ezimbili, okuvumela ibhodi lezinkuni libekwe kuwo wonke umshini wobubanzi, ngisho nangale kwendawo yetafula. Ukukhiqiza kwakho, noma ngabe ukusika nokuqopha, kuzovumelana nezimo futhi kusebenze kahle.

Isakhiwo Esizinzile Nephephile

◾ I-Adjustable Air Assist

Ukusiza komoya kungaphephetha udoti nama-chips ebusweni bokhuni, futhi kuvikele i-MDF ekushiseni ngesikhathi sokusika nokuqoshwa nge-laser. Umoya ocindezelwe ophuma empompini yomoya ulethwa emigqeni eqoshiwe futhi usika ngombhobho, ususa ukushisa okwengeziwe okuqoqwe ekujuleni. Uma ufuna ukuzuza ukusha nombono wobumnyama, lungisa ingcindezi nosayizi wokugeleza komoya ngesifiso sakho. Noma yimiphi imibuzo ongasithinta ngayo uma udidekile ngalokho.

◾ I-Exhaust Fan

Igesi ehlala isikhathi eside ingamuncwa ku-fan yokukhipha umoya ukuze kuqedwe intuthu ehlupha i-MDF nokusika kwe-laser. Isistimu yokungenisa umoya ephansi ehambisana nesihlungi somusi ingakhipha igesi engcolile futhi ihlanze indawo yokucubungula.

◾ Isekhethi ephephile

Ukusebenza okushelelayo kwenza imfuneko yesekethe yokusebenza kahle, ukuphepha kwayo okuyisisekelo sokukhiqizwa kokuphepha.

◾ Isitifiketi se-CE

Njengoba unelungelo elingokomthetho lokumaketha nokusabalalisa, umshini we-MimoWork Laser uziqhenye ngekhwalithi yawo eqinile nethembekile.

▶ Izinketho ezifanele zisiza ukusika i-plywood ye-laser ngokwezifiso

Thuthukisa izinketho ongakhetha kuzo

Ikhamera ye-CCD

I-DC Brushless Motor

I-Servo Motor

I-Auto Focus

I-Mix Laser Head

Ibhola & Isikulufa

Khetha ukucushwa kwe-laser nezinketho ezifanele

Sazise izidingo zakho futhi sikunikeze isisombululo se-laser esenziwe ngokwezifiso!

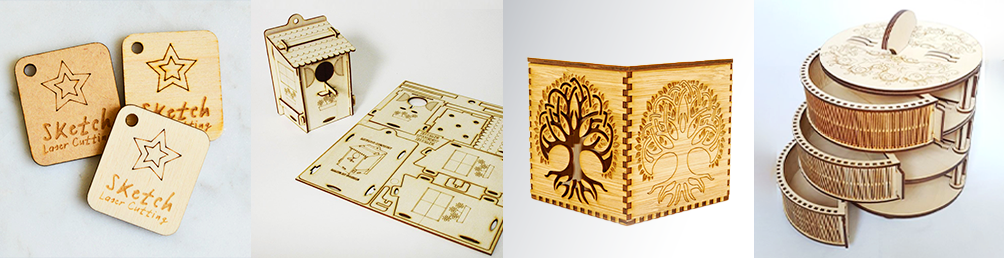

I-Plywood ye-Laser Cutting & Engraving

I-Plywood yenziwe ngamapulangwe amaningi amancane amancane nama-glues anamathele ezingqimbeni. Njengento evamile yokwenza ubuciko, ukuhlanganisa imodeli, iphakheji, ngisho nefenisha, i-MimoWork yahlola izitayela ezihlukene ezihlanganisa ukusika nokuqopha ku-plywood. Kukhona ezinye izinhlelo zokusebenza ze-plywood ezivela kumsiki we-laser we-MimoWork.

Izithombe Dlulisa amehlo

Ibhokisi Lesitoreji, Imodeli Yokwakha, Ifenisha, Iphakheji, Umhlangano Wamathoyizi,I-Plywood eguquguqukayo (okuhlangene)…

Imibukiso Yevidiyo

Ukwenza Isipho Sokhuni sikaKhisimusi usebenzisa i-Laser Cutter

◆ Unqenqema olubushelelezi ngaphandle kwe-burr

◆ Indawo ehlanzekile nehlanzekile

◆ Imivimbo ye-laser eguquguqukayo idala amaphethini ahlukahlukene

Imboni: Ukuhlobisa, Ukukhangisa, Ifenisha, Umkhumbi, Inqola, Ezokundiza

I-Laser Cut Holes ku-25mm Plywood

I-Laser Plywood enobugqinsi ayilula neze, kodwa ngokusethwa okufanele kanye Namalungiselelo, i-laser cut plywood ingazwakala njengomoya ohelezayo. Kule vidiyo, sibonise i-CO2 Laser Cut 25mm Plywood kanye nezigcawu ezithile "Zokuvutha" nezinongo.

Ingabe ufuna ukusebenzisa isisiki se-laser esinamandla amakhulu njenge-450W Laser Cutter? Qiniseka ukuthi unezinguquko ezifanele!

I-Laser Cutting Plywood: Yazi iCanvas yakho

I-plywood itholakala ngobukhulu obuhlukahlukene, kusukela ku-1/8 "kuya ku-1". I-plywood ewugqinsi inikeza ukuzinza okukhulu nokumelana ne-warping, kodwa ingaba nezinselele uma usebenzisa isisiki se-laser ngenxa yobunzima obukhulayo bokusika. Uma usebenza nge-plywood ezacile, ukulungisa izilungiselelo zamandla we-laser cutter kungase kudingeke ukuze kuvinjelwe ukushiswa kwempahla.

Lapho ukhetha i-plywood yokusika i-laser, ukucabangela okusanhlamvu kokhuni kubalulekile, njengoba kuthonya imiphumela yokusika nokuqopha. Ukuze uthole ukusikeka okunembile nokuhlanzekile, khetha i-plywood enohlamvu oluqondile, kuyilapho okusanhlamvu okugagasi kungafinyelela ukubukeka okunembayo, okuhambisana nemigomo yobuhle yephrojekthi yakho.

Kunezinhlobo ezintathu eziyinhloko ze-plywood: i-hardwood, i-softwood, ne-composite. I-Hardwood plywood, eklanywe ngokhuni oluqinile njenge-maple noma i-oki, inokuminyana okuphezulu nokuqina, okuyenza ilungele amaphrojekthi aqinile.

Noma kunjalo, kungaba inselele ukusika nge-laser cutter. I-Softwood plywood, eyenziwe ngezinkuni ezithambile njengophayini noma i-fir, ayinawo amandla e-hardwood plywood kodwa kulula kakhulu ukuyisika. I-plywood ehlanganisiwe, inhlanganisela yezinkuni eziqinile kanye ne-softwoods, ihlanganisa amandla e-hardwood plywood kalula ukusika okutholakala ku-softwood plywood.

Amathiphu wokusika i-Plywood Laser (Umdwebo)

# Yenza isivivinyo kuqala ngaso sonke isikhathi sidingeka ngenxa yezinhlobonhlobo zeglues nezinqwaba zokhuni.

# Ukudambisa i-plywood uma ingeyisicaba ngaphambi kokusika i-laser.

# Ukuqinisekisa indawo ekhanyayo nengenabala, unganamathela amateyipu ku-plywood ngaphambi kokusika noma ukuqoshwa kwe-laser.

(us the reverse uma ufuna ubumnyama nobunsundu ukuze udale isitayela sakudala.)

I-Plywood evamile yokusika i-Laser (Umdwebo)

• Jarrah

• I-Hoop Pine

• I-European Beech Plywood

• I-Bamboo Plywood

• I-Birch Plywood

Noma yimiphi imibuzo mayelana ne-plywood laser cutting & eqoshiwe

I-Plywood Laser Cutter Machine

ngokhuni kanye ne-acrylic laser cutting

• Ifanele izinto eziqinile zefomethi enkulu

• Ukusika ukujiya okuningi ngamandla ozikhethela we-laser tube

ngokhuni kanye ne-acrylic laser engraving

• Idizayini elula futhi ehlangene

• Kulula ukusebenza kwabaqalayo