I-Acrylic (PMMA) I-Laser Cutter

Uma ufuna ukusika amashidi e-acrylic(PMMA, Plexiglass, Lucite) ukwenza ezinye izimpawu ze-acrylic, imiklomelo, imihlobiso, ifenisha, ngisho namadeshibhodi ezimoto, okokuvikela, noma okunye? Iliphi ithuluzi lokusika eliyisinqumo esingcono kakhulu?

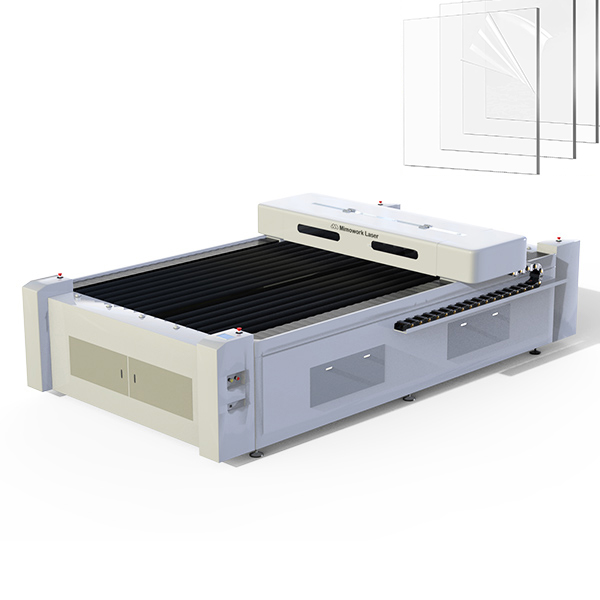

Sincoma umshini we-laser we-acrylic onezinga lezimboni kanye nebanga lokuzilibazisa.

Isivinini sokusika esisheshayo kanye nomphumela omuhle kakhulu wokusikayizinzuzo ezivelele zemishini yokusika ye-acrylic laser ozoyithanda.

Ngaphandle kwalokho, umshini we-laser we-acrylic ubuye ube umqophi we-laser we-acrylic, ongakwaziqopha amaphethini athambile futhi amahle nezithombe emashidini e-acrylic. Ungenza ibhizinisi langokwezifiso nge-acrylic laser engraver encane, noma wandise ukukhiqizwa kwakho kwe-acrylic ngokutshala imali emshinini wokusika we-laser wefomethi ye-acrylic enkulu yemboni, ongaphatha amashidi e-acrylic amakhulu futhi aminyene ngesivinini esiphezulu, esihle kakhulu ekukhiqizeni kwakho ngobuningi.

Yini ongayenza nge-laser cutter engcono kakhulu ye-acrylic? Qhubeka ukuze uhlole okwengeziwe!

Vula Amandla Aphelele We-Acrylic Laser Cutter

Ukuhlolwa Kwezinto: I-Laser Cutting 21mm Thick Acrylic

Umphumela Wokuhlola:

I-Higher Power Laser Cutter ye-Acrylic inekhono lokusika elimangalisayo!

Ingakwazi ukusika eshidini le-acrylic eliwugqinsi elingu-21mm, futhi idale umkhiqizo we-acrylic oqediwe wekhwalithi ephezulu onomphumela wokusika opholishwe ngamalangabi.

Kumashidi ama-acrylic azacile angaphansi kuka-21mm, umshini wokusika we-laser uwaphatha kalula futhi!

| Indawo yokusebenza (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Isoftware | Isoftware ye-MimoCUT |

| Laser Amandla | 100W/150W/300W/450W |

| Umthombo we-Laser | I-CO2 Glass Laser Tube noma i-CO2 RF Metal Laser Tube |

| IMechanical Control System | Isinyathelo Motor Belt Control |

| Ithebula Lokusebenza | I-Honey Comb Working Table noma I-Knife Strip Working Table |

| Isivinini esikhulu | 1~400mm/s |

| Isivinini Sokusheshisa | 1000~4000mm/s2 |

Izinzuzo ezivela ku-Acrylic Laser Cutting & Engraving

Unqenqema olupholishiwe nekristalu

Ukusika okuguquguqukayo komumo

Ukuqoshwa kwephethini okuyinkimbinkimbi

✔Amaphethelo wokusika acwebezeliswe ngokuphelele ekusebenzeni okukodwa

✔Asikho isidingo sokubopha noma ukulungisa i-acrylic ngenxa yokucubungula ngaphandle kokuthinta

✔Ukucubungula okuguquguqukayo kwanoma yimuphi umumo noma iphethini

✔Akukho ukungcola njengokugaya okusekelwa i-fume extractor

✔Ukusika iphethini enembile ngezinhlelo zokuqaphela optical

✔Ukwenza ngcono ukusebenza kahle kusuka ekuphakeleni, ukusika kuya kokwamukela ngethebula lokusebenza le-shuttle

Imishini Edumile Yokusika I-Acrylic Laser

• Amandla eLaser: 100W/150W/300W

• Indawo yokusebenza: 1300mm * 900mm (51.2” * 35.4 ”)

• Amandla eLaser: 150W/300W/450W

• Indawo yokusebenza: 1300mm * 2500mm (51” * 98.4”)

Unentshisekelo ku

ACRYLIC LASER UKUSIKA UMSHINI

I-Value eyengeziwe evela ku-MimoWork Laser Options

✦Ikhamera ye-CCDinikeza umshini umsebenzi wokuqashelwa wokusika i-acrylic ephrintiwe eduze kwekhonta.

✦Ukucubungula okusheshayo futhi okuzinzile kungenziwa nge-i-servo motor kanye ne-brushless motor.

✦Ukuphakama kokugxila okuhle kakhulu kungatholakala ngokuzenzakalelayo ngeauto focuslapho usika izinto eziwugqinsi ngokuhlukile, asikho isidingo sokulungiswa ngesandla.

✦I-Fume Extractorkungasiza ukususa amagesi ahlala isikhathi eside, iphunga elimnandi elingase likhiqizwe lapho i-CO2 laser icubungula izinto ezithile ezikhethekile, nezinsalela ezihamba emoyeni.

✦I-MimoWork inohlu lweLaser Cutting Amathebulangezinto ezahlukene kanye nezicelo. Iikhekheba lezinyosi laser cutting umbhedeilungele ukusika nokuqopha izinto ezincane ze-acrylic, kanyeitafula lokusika ummesekungcono ukusika i-acrylic ewugqinsi.

I-acrylic ephrintiwe nge-UV enombala ocebile nephethini iye yanda kakhulu.Indlela yokusika i-acrylic ephrintiwe ngokunembe futhi ngokushesha? I-CCD Laser Cutter iyisinqumo esihle kakhulu.

Ifakwe nekhamera ye-CCD ehlakaniphile futhiI-Optical Recognition Software, ekwazi ukubona nokubeka amaphethini, futhi iqondise ikhanda le-laser ukuze lisike ngokunembile i-contour.

Okhiye be-Acrylic, amabhodi okukhangisa, imihlobiso, nezipho ezikhumbulekayo ezenziwe nge-acrylic ephrintiwe isithombe, kulula ukuqedela ngomshini wokusika we-acrylic laser ophrintiwe.

Ungasebenzisa i-laser ukusika i-acrylic ephrintiwe ngomklamo wakho owenziwe ngokwezifiso nokukhiqiza ngobuningi, okulula futhi okuphumelelayo kakhulu.

Ungasika kanjani izinto eziphrintiwe ngokuzenzakalela | I-Acrylic & Wood

Izicelo ze-Acrylic Laser Cutting & Engraving

• Izibonisi Zokukhangisa

• Ukwakhiwa Kwemodeli Yezakhiwo

• Ukulebula kweNkampani

• Izindebe ezithambile

• I-Acrylic Ephrintiwe

• Ifenisha Yesimanje

• Amabhodi okukhangisa angaphandle

• Isitendi Somkhiqizo

• Izimpawu Zomdayisi

• Ukususwa kweSprue

• Ubakaki

• Ukuthenga ezitolo

• I-Cosmetic Stand

Ukusebenzisa i-Acrylic Laser Cutter

Senze Uphawu Lwe-Acrylic Nokuhlobisa

Indlela yokusika i-Laser Cake Topper

Indlela yokusika imihlobiso ye-acrylic (i-snowflake)

Laser Cutting kanye Engraving Acrylic Business

Imuphi Iphrojekthi Ye-Acrylic Osebenza Nayo?

Amathiphu Ukwabelana: Ukuze Perfect Acrylic Laser Cutting

◆Phakamisa ipuleti le-acrylic ukuze lingathinti itafula lokusebenza ngenkathi usika

◆ Ishidi le-acrylic elihlanzekile eliphakeme lingafinyelela umphumela ongcono wokusika.

◆ Khetha i-laser cutter enamandla afanele emaphethelweni acwebezeliswe ilangabi.

◆Ukuvunguza kufanele kube kuncane ngangokunokwenzeka ukuze kugwenywe ukusakazeka kokushisa okungase futhi kuholele onqenqemeni oluvuthayo.

◆Gcoba ibhodi le-acrylic ohlangothini olungemuva ukuze ukhiqize umphumela wokubheka kusukela ngaphambili.

Isifundo Sevidiyo: Ungasika Kanjani I-Laser & Uqophe I-Acrylic?

I-FAQ ye-Laser Cutting Acrylic (PMMA, Plexiglass, Lucite)

1. Ungakwazi yini ukusika i-acrylic nge-laser cutter?

I-Laser cutting acrylic sheet iyindlela evamile futhi ethandwayo ekukhiqizeni i-acrylic. Kodwa ngezinhlobo ezahlukene zamashidi e-acrylic afana ne-acrylic extruded, i-acrylic eqoshiwe, i-acrylic ephrintiwe, i-acrylic ecacile, i-mirror acrylic, njll, udinga ukukhetha umshini we-laser ofanele izinhlobo eziningi ze-acrylic.

Sincoma i-CO2 Laser, engumthombo we-laser esebenziseka kalula kwe-acrylic, futhi ikhiqiza umphumela omuhle wokusika kanye nomthelela wokuqopha ngisho nange-acrylic ecacile.Siyazi ukuthi i-diode laser iyakwazi ukusika i-acrylic encane kodwa kuphela i-acrylic emnyama nemnyama. Ngakho-ke i-CO2 Laser cutter iyisinqumo esingcono sokusika nokuqopha i-acrylic.

2. Indlela yokusika i-acrylic nge-laser?

I-Laser cutting acrylic iyinqubo elula futhi ezenzakalelayo. Ngezinyathelo ezi-3 kuphela, uzothola umkhiqizo omuhle kakhulu we-acrylic.

Isinyathelo1. Beka ishidi le-acrylic etafuleni lokusika i-laser.

Isinyathelo2. Setha amandla e-laser nesivinini ku-software ye-laser.

Isinyathelo3. Qala ukusika nokuqopha nge-laser.

Mayelana nomhlahlandlela oningiliziwe wokusebenza, uchwepheshe wethu we-laser uzokunikeza isifundo esisebenzayo nesiphelele ngemuva kokuthenga umshini we-laser. Ngakho-ke noma yimiphi imibuzo, zizwe ukhululekile ukuyiphendulakhuluma nochwepheshe bethu be-laser.

@ Email: info@mimowork.com

☏ WhatsApp: +86 173 0175 0898

3. Ukusika nokuqopha nge-Acrylic: CNC VS. I-Laser?

Amarutha e-CNC asebenzisa ithuluzi lokusika elijikelezayo ukuze asuse izinto ezibonakalayo, ezifanele i-acrylic ewugqinsi (kufika ku-50mm) kodwa ngokuvamile adinga ukupholishwa.

Abasiki be-laser basebenzisa i-laser beam ukuze bancibilike noma bahwamulise impahla, banikeze ukunemba okuphezulu nemiphetho ehlanzekile ngaphandle kwesidingo sokupholisha, okungcono kakhulu nge-acrylic ezacile (kufika ku-20-25mm).

Mayelana nomphumela wokusika, ngenxa ye-laser enhle ye-laser cutter, ukusika kwe-acrylic kunembe kakhulu futhi kuhlanzekile kunokusika kwe-cnc router.

Ngesivinini sokusika, irutha ye-CNC ishesha kune-laser cutter ekusikeni i-acrylic. Kepha ngokuqopha i-acrylic, i-laser iphakeme kunerutha ye-CNC.

Ngakho-ke uma unentshisekelo esihlokweni, futhi udidekile ngokuthi ungakhetha kanjani phakathi kwe-cnc ne-laser cutter, bheka ividiyo noma ikhasi ukuze ufunde kabanzi:I-CNC VS Laser yokusika nokuqopha i-acrylic

4. Ungakhetha kanjani i-acrylic efanelekile yokusika nokuqopha nge-laser?

I-acrylic iza ngezinhlobo ezahlukene. Ingakwazi ukuhlangabezana nezidingo ezihlukahlukene ngokuhluka kokusebenza, imibala, nomthelela wobuhle.

Yize abantu abaningi bazi ukuthi amashidi e-acrylic afakwe nakhishiwe afanele ukucutshungulwa nge-laser, bambalwa abazazi izindlela zabo ezicacile zokusebenzisa i-laser.

Amashidi e-acrylic asakazwayo abonisa imiphumela ephakeme yokuqopha uma kuqhathaniswa namashidi akhishiwe, okuwenza afaneleke kakhulu izinhlelo zokusebenza zokuqoshwa nge-laser. Ngakolunye uhlangothi, amashidi akhishiwe abiza kakhulu futhi afaneleka kangcono izinjongo zokusika nge-laser.

5. Ungakwazi yini laser ukusika oversized acrylic izimpawu?

Yebo, ungakwazi ukusika izimpawu ze-acrylic ezinkulu nge-laser usebenzisa i-laser cutter, kodwa kuya ngosayizi wombhede womshini. Ama-laser cutter ethu amancane anekhono lokudlula, akuvumela ukuthi usebenze ngezinto ezinkulu ezingaphezu kosayizi wombhede.

Futhi ngamashidi e-acrylic abanzi futhi amade, sinomshini omkhulu wokusika we-laser onefomethi engu-1300mm * 2500mm indawo yokusebenza, okulula ukuphatha izimpawu ezinkulu ze-acrylic.

Noma yimiphi imibuzo mayelana nokusika kwe-laser nokuqoshwa kwe-laser ku-acrylic?

Sazise futhi sikunikeze izeluleko ezengeziwe nezisombululo!

Ngokuthuthuka kobuchwepheshe kanye nokwenza ngcono amandla e-laser, ubuchwepheshe be-CO2 laser buya kuqina kakhulu ekusetshenzisweni kwe-acrylic.

Kungakhathaliseki ukuthi ingilazi ye-acrylic (GS) noma i-extruded (XT) ye-acrylic,i-laser iyithuluzi elikahle lokusika nokuqopha i-acrylic (plexiglass) enezindleko eziphansi kakhulu zokucubungula uma kuqhathaniswa nemishini yokugaya evamile.

Iyakwazi ukucubungula ukujula kwezinto ezihlukahlukene,I-MimoWork Laser Cuttersngomklamo wokucushwa owenziwe ngokwezifiso namandla afanele angahlangabezana nezidingo ezihlukene zokucubungula, okuholela kuma-workpieces e-acrylic aphelelei-crystal-clear, imiphetho enqunyiwe ebusheleleziekusebenzeni okukodwa, asikho isidingo sokupholisha ilangabi okwengeziwe.

Ukusika kwe-Laser okuphrofeshinali nokufanelekile ku-Acrylic

Umshini we-laser we-acrylic ungasika amashidi ama-acrylic amancane nawugqinsi anomkhawulo wokusika ohlanzekile futhi ophucuziwe futhi uqophe amaphethini amahle anemininingwane nezithombe kumaphaneli e-acrylic.

Ngejubane eliphezulu lokucubungula kanye nesistimu yokulawula idijithali, umshini wokusika we-CO2 laser we-acrylic ungafinyelela ukukhiqizwa ngobuningi ngekhwalithi ephelele.

Uma unebhizinisi elincane noma elenziwe ngomthungi lemikhiqizo ye-acrylic, umqophi omncane we-laser we-acrylic uyisinqumo esihle. Kulula ukuyisebenzisa futhi kuyabiza!