I-Laser Ifanelwe Ephelele Yokusika I-Acrylic! Ngikusho ngani lokho? Ngenxa yokuhambisana kwayo okubanzi nezinhlobo ezahlukene zama-acrylic namasayizi, ukunemba okuphezulu kakhulu kanye nesivinini esisheshayo ekusikeni i-acrylic, ukufunda nokusebenza okulula, nokunye. Kungakhathaliseki ukuthi ungumuntu othanda ukuzilibazisa, ukusika imikhiqizo ye-acrylic yebhizinisi, noma ukusetshenziswa kwezimboni, i-laser cutting acrylic ihlangabezana cishe nazo zonke izidingo. Uma uphishekela ikhwalithi enhle kakhulu nokuvumelana nezimo okuphezulu, futhi ufuna ukuba yingcweti ngokushesha, i-acrylic laser cutter izoba yisinqumo sakho sokuqala.

Izinzuzo Laser Cutting Acrylic

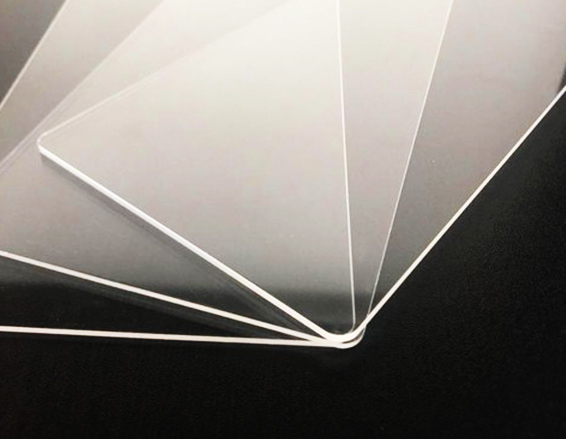

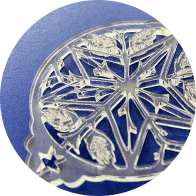

✔ I-Smooth Cutting Edge

Amandla e-laser anamandla anganqamula ishidi le-acrylic aqonde ngqo. Ukushisa kuvala futhi kupholishe unqenqema ukuze lushelele futhi luhlanzeke.

✔ Ukusika Ongathintana Naye

I-Laser cutter ifaka ukucubungula ngaphandle kokuthinta, ukususa ukukhathazeka mayelana nokuklwebheka kwezinto kanye nokuqhekeka ngoba akukho ukucindezela komshini. Asikho isidingo sokushintsha amathuluzi nezingcezu.

✔ Ukunemba okuphezulu

Ukunemba okuphezulu kakhulu kwenza i-acrylic laser cutter ibe amaphethini ayinkimbinkimbi ngokuya ngefayela eliklanywe. Ifanele ukuhlobisa kwe-acrylic yangokwezifiso kanye nezinsiza zezimboni nezokwelapha.

✔ Isivinini nokusebenza kahle

Amandla e-laser aqinile, akukho ukucindezeleka komshini, nokulawula okuzenzakalelayo kwedijithali, kwenyusa kakhulu isivinini sokusika kanye nokusebenza kahle konke kokukhiqiza.

✔ Ukuhlukahluka

Ukusika kwe-laser ye-CO2 kunemisebenzi eminingi ukusika amashidi e-acrylic anobukhulu obuhlukahlukene. Ilungele kokubili izinto ze-acrylic ezincane neziwugqinsi, ezinikeza ukuguquguquka kwezicelo zephrojekthi.

✔ Imfucuza Yezinto Ezincane

I-beam egxilile ye-CO2 laser inciphisa udoti wezinto ezibonakalayo ngokudala ububanzi be-kerf obuncane. Uma usebenza ngokukhiqiza ngobuningi, isofthiwe ehlakaniphile yokwenza isidleke se-laser ingathuthukisa indlela yokusika, futhi yandise izinga lokusebenzisa impahla.

I-Crystal-clear edge

Iphethini yokusika eyinkimbinkimbi

Izithombe eziqoshwe nge-acrylic

▶ Bheka ngokucophelela: Iyini i-Laser Cutting Acrylic?

I-Laser Cutting I-Acrylic Snowflake

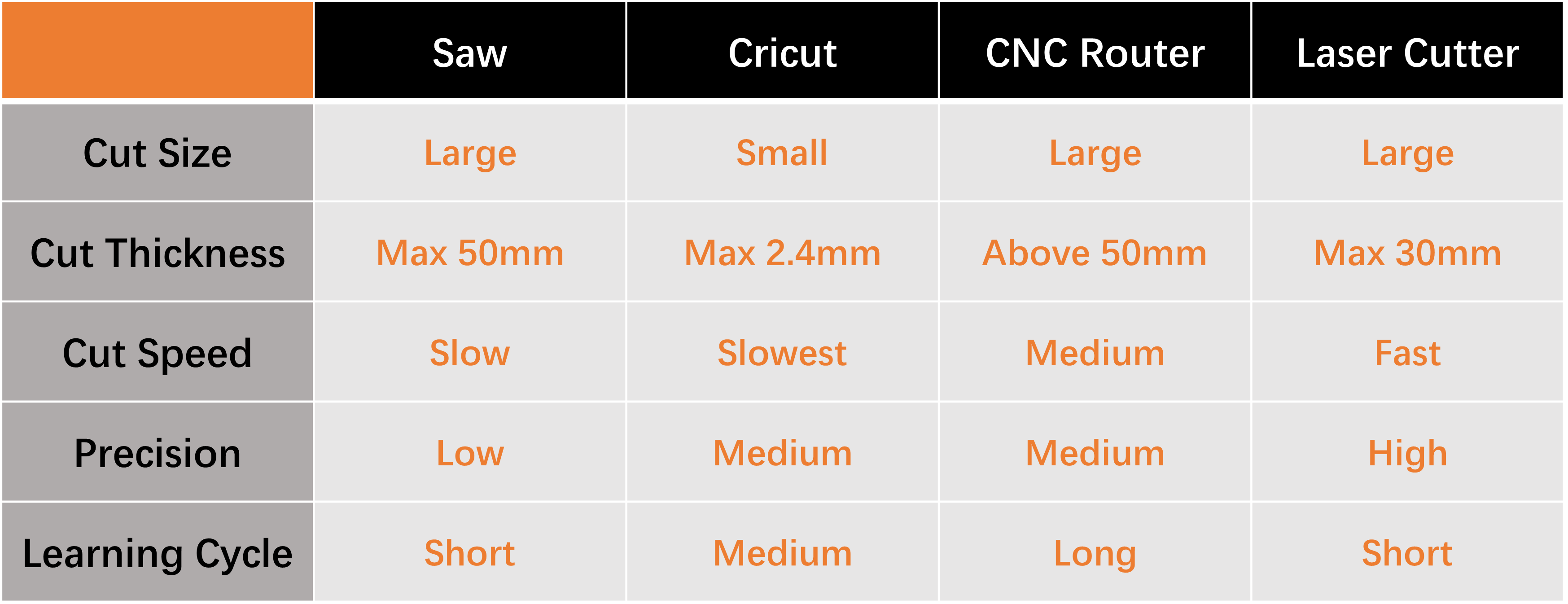

4 Amathuluzi Okusika - Ungasika Kanjani I-Acrylic?

I-Jigsaw & Circular Saw

Isaha, njengesaha eliyindilinga noma i-jigsaw, iyithuluzi lokusika eliguquguqukayo elivame ukusetshenziselwa i-acrylic. Ifanele ukusikeka okuqondile nokugobile, okuyenza ifinyeleleke kumaphrojekthi e-DIY nezinhlelo zokusebenza zesilinganiso esikhulu.

I-Cricut

Umshini we-Cricut iyithuluzi lokusika elinembayo elenzelwe ubuciko kanye namaphrojekthi we-DIY. Isebenzisa i-blade enhle ukusika izinto ezahlukahlukene, kufaka phakathi i-acrylic, ngokunemba nangokulula.

I-CNC Router

Umshini wokusika olawulwa ngekhompuyutha onenqwaba yezingcezu zokusika. Iguquguquka kakhulu, ikwazi ukuphatha izinto ezahlukahlukene, kufaka phakathi i-acrylic, kokubili kokusika okuyinkimbinkimbi kanye nokusika okukhulu.

I-Laser Cutter

Umsiki we-laser usebenzisa i-laser beam ukusika i-acrylic ngokunemba okuphezulu. Ivame ukusetshenziswa ezimbonini ezidinga imiklamo eyinkimbinkimbi, imininingwane emihle, kanye nekhwalithi yokusika engaguquki.

Ungayikhetha kanjani i-Acrylic Cutter Suits You?

imbangela yayo

Ukuguquguquka, Ukuvumelana nezimo, Ukusebenza kahle…

☻Ikhono elihle kakhulu le-Laser lokusika i-Acrylic:

Amanye amasampuli we-Laser Cutting Acrylic

• Isibonisi Sezikhangiso

• Ibhokisi Lokugcina

• Izimpawu

• Indondo

• Imodeli

• I-keychain

• Ikhekhe Lekhekhe

• Isipho Nokuhlobisa

• Ifenisha

• Ubucwebe

▶ Ingabe I-Laser Cutting Acrylic Inobuthi?

▶ Ungasikwa Kanjani I-Laser Sula I-Acrylic?

▶ Iyiphi I-Laser Engcono Kakhulu Ye-Acrylic Cutting?

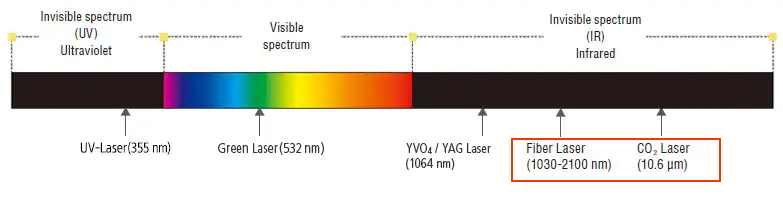

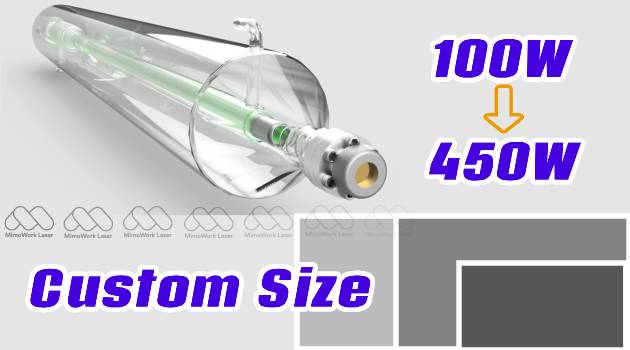

Ngokusika i-acrylic ngokuqondile, i-CO2 laser ivame ukubhekwa njengenketho engcono kakhulu ngenxa yezimpawu zayo ze-wavelength, ehlinzeka ngokusikeka okuhlanzekile nokunembe kuwo wonke ama-acrylic ahlukahlukene. Kodwa-ke, izidingo ezithile zamaphrojekthi akho, okuhlanganisa ukucatshangelwa kwesabelomali kanye nezinto zokwakha ohlela ukusebenza ngazo, nazo kufanele zibe nomthelela ekukhetheni kwakho. Ngaso sonke isikhathi hlola imininingwane yohlelo lwe-laser futhi uqinisekise ukuthi luhambisana nezinhlelo ozihlosile.

▶ Kunconywe i-CO2 Laser Cutter ye-Acrylic

Kusuka ku-MimoWork Laser Series

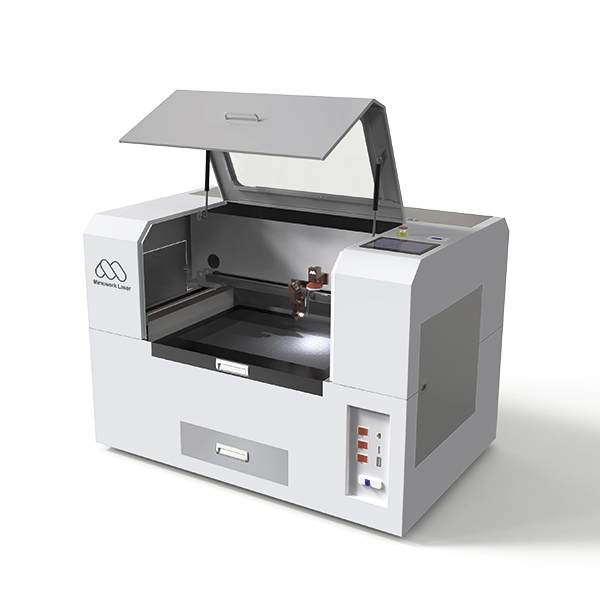

Usayizi Wethebula Lokusebenza:600mm * 400mm (23.6” * 15.7”)

Izinketho zamandla e-Laser:65W

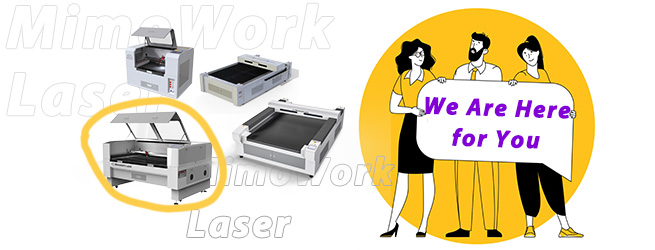

Uhlolojikelele lwe-Desktop Laser Cutter 60

Imodeli Yedeskithophu - I-Flatbed Laser Cutter 60 iziqhayisa ngomklamo ohlangene onciphisa ngempumelelo izidingo zendawo ngaphakathi kwegumbi lakho. Ihlala kahle phezu kwetafula, izethula njengenketho efanelekile yezinga lokungena kwabaqalayo abahlanganyela ekwakhiweni kwemikhiqizo emincane yangokwezifiso, njengemiklomelo ye-acrylic, imihlobiso, nobucwebe.

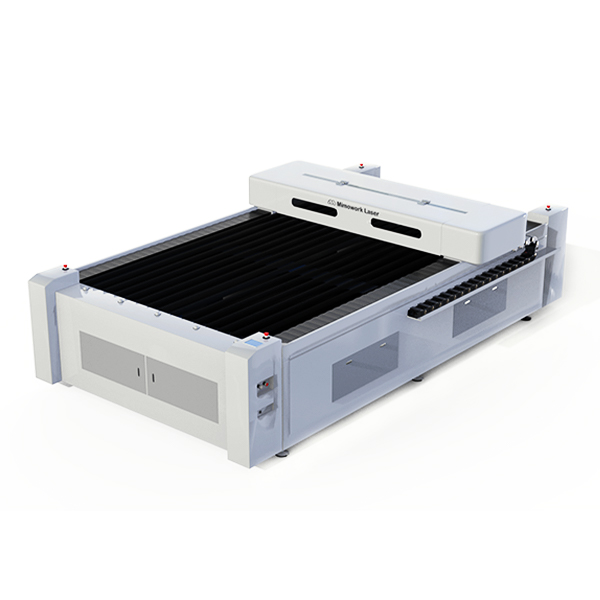

Usayizi Wethebula Lokusebenza:1300mm * 900mm (51.2” * 35.4 ”)

Izinketho zamandla e-Laser:100W/150W/300W

Uhlolojikelele lwe-Flatbed Laser Cutter 130

I-Flatbed Laser Cutter 130 iyisinqumo esithandwa kakhulu sokusika i-acrylic. Idizayini yayo yetafula lokusebenza yokudlula ikwenza ukwazi ukusika usayizi omkhulu wamashidi e-acrylic ubude kunendawo yokusebenza. Ngaphezu kwalokho, inikeza ukuguquguquka ngokufaka amashubhu e-laser anoma yisiphi isilinganiso samandla ukuze kuhlangatshezwane nezidingo zokusika i-acrylic enobukhulu obuhlukahlukene.

Usayizi Wethebula Lokusebenza:1300mm * 2500mm (51.2” * 98.4”)

Izinketho zamandla e-Laser:150W/300W/500W

Uhlolojikelele lwe-Flatbed Laser Cutter 130L

I-Flatbed Laser Cutter 130L enkulu ifaneleka kahle ukusika amashidi amakhulu e-acrylic, okuhlanganisa namabhodi asetshenziswa njalo angu-4ft x 8ft atholakala emakethe. Lo mshini uklanyelwe ngokukhethekile ukuhlalisa amaphrojekthi amakhulu njengezimpawu zokukhangisa zangaphandle, ama-partitions asendlini, nezinye izinto zokuzivikela. Ngenxa yalokho, igqama njengenketho ekhethwayo ezimbonini ezifana nokukhangisa nokukhiqiza ifenisha.

▶ Umhlahlandlela Wokusebenza: Ungayisika Kanjani I-Acrylic Laser?

Kuye ngohlelo lwe-CNC kanye nezingxenye zomshini ezinembile, umshini wokusika we-laser we-acrylic uzenzakalela futhi kulula ukuwusebenzisa. Udinga nje ukulayisha ifayela lokuklama kukhompyutha, futhi usethe imingcele ngokuya nezici ezibonakalayo kanye nezidingo zokusika. Okusele kuzoshiyelwa ku-laser. Isikhathi sokukhulula izandla zakho futhi wenze kusebenze ubuhlakani kanye nemicabango engqondweni.

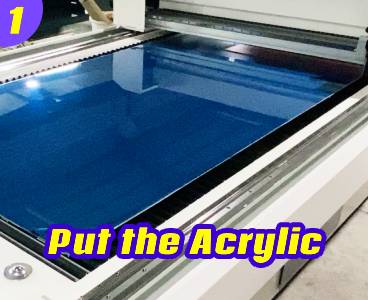

Isinyathelo 1. lungiselela umshini kanye ne-acrylic

Ukulungiswa kwe-Acrylic:gcina i-acrylic flat futhi ihlanzekile phezu kwetafula lokusebenza, futhi kangcono ukuhlola usebenzisa scrap ngaphambi real laser cutting.

Umshini we-Laser:thola usayizi we-acrylic, usayizi wephethini yokusika, nokuqina kwe-acrylic, ukukhetha umshini ofanele.

▶

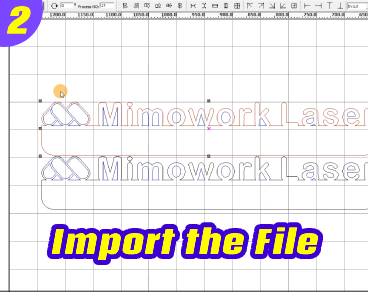

Isinyathelo 2. setha isofthiwe

Ifayela Lokuklama:ngenisa ifayela lokusika ku-software.

Isilungiselelo se-Laser: Khuluma nochwepheshe wethu we-laser ukuze uthole amapharamitha wokusika ajwayelekile. Kepha izinto ezahlukahlukene zinokujiya okuhlukile, ubumsulwa, kanye nokuminyana, ngakho-ke ukuhlola ngaphambili kuyisinqumo esingcono kakhulu.

▶

Isinyathelo 3. laser cut acrylic

Qala ukusika i-Laser:I-laser izosika iphethini ngokuzenzakalelayo ngokwendlela enikeziwe. Khumbula ukuvula umoya ukuze ususe intuthu, futhi wehlise umoya ovunguzayo ukuze uqinisekise ukuthi unqenqema lubushelelezi.

Isifundo Sevidiyo: I-Laser Cutting & Engraving Acrylic

▶ Ungakhetha kanjani i-Laser Cutter?

Kunokucatshangelwa okumbalwa lapho ukhetha umsiki we-laser we-acrylic ofanele wephrojekthi yakho. Okokuqala udinga ukwazi imininingwane ebalulekile njengokuqina, usayizi, nezici. Futhi Thola izidingo zokusika noma zokuqopha njengokunemba, ukulungiswa kokuqoshwa, ukusebenza kahle kokusika, usayizi wephethini, njll. Okulandelayo, uma unezidingo ezikhethekile zokukhiqiza okungashisi umusi, ukuhlomisa isikhiphi somusi siyatholakala. Ngaphezu kwalokho, udinga ukucabangela isabelomali sakho kanye nentengo yomshini. Siphakamisa ukuthi ukhethe umhlinzeki womshini we-laser ochwepheshe ukuze uthole izindleko ezingabizi, isevisi ephelele, kanye nobuchwepheshe bokukhiqiza obuthembekile.

Kudingeka Ucabangele

> Yiluphi ulwazi okufanele ulunikeze?

> Imininingwane yethu yokuxhumana

> Izindleko zomshini wokusika we-Acrylic laser

> Ukuthi ukhethe izinketho zomshini we-laser

▶ Ukusebenzisa Umshini

> Yeka ukushuba acrylic kungaba laser ukusika?

Ukuqina kwe-acrylic okunganqanyulwa yi-CO2 laser kuncike emandleni athile e-laser kanye nezici zesistimu yokusika i-laser. Ngokuvamile, ama-laser e-CO2 ayakwazi ukusika amashidi e-acrylic anobukhulu obuhlukahlukene obufika ku-30mm. Ukwengeza, izinto ezifana nokugxilwa kwe-laser beam, ikhwalithi ye-optics, kanye nomklamo othize we-laser cutter kungaba nomthelela ekusebenzeni kokusika.

Ngaphambi kokuzama ukusika amashidi e-acrylic aminyene, kuhle ukuthi uhlole imininingwane enikezwe umkhiqizi we-CO2 laser cutter yakho. Ukuhlola izingcezu ezilahliwe ze-acrylic ezinobukhulu obuhlukahlukene kungasiza ekunqumeni izilungiselelo ezilungile zomshini wakho othize.

Inselele: I-Laser Cutting 21mm Thick Acrylic

> Indlela yokugwema laser ukusika intuthu acrylic?

> Okokufundisa kwe-acrylic laser cutter

Ungakuthola kanjani ukugxila kwe-laser lens?

Indlela yokufaka i-laser tube?

Indlela yokuhlanza i-laser lens?

Funda kabanzi mayelana ne-Laser Cutting Acrylic,

Chofoza lapha ukuze ukhulume nathi!

I-CO2 Laser Cutter ye-Acrylic iwumshini ohlakaniphile futhi ozenzakalelayo kanye nozakwethu onokwethenjelwa ekusebenzeni nasekuphileni. Ngokuhlukile kokunye ukucutshungulwa kwemishini kwendabuko, abasiki be-laser basebenzisa uhlelo lokulawula lwedijithali ukulawula indlela yokusika nokunemba kokusika. Futhi ukwakheka komshini ozinzile kanye nezingxenye kuqinisekisa ukusebenza kahle.

Noma yikuphi ukudideka noma imibuzo ye-acrylic laser cutter, vele usibuze nganoma yisiphi isikhathi

Isikhathi sokuthumela: Dec-11-2023