Indlela yokusika i-Laser Sula i-Acrylic

Amathiphu kanye namaqhinga for Perfect Acrylic Cutting

I-laser-cutting acrylic ecacile iyinhlanganoinqubo evamileesetshenziswa ezimbonini ezahlukene ezifanaukwenza izimpawu, ukumodela kwezakhiwo, kanye ne-prototyping yomkhiqizo.

Inqubo ihilela ukusebenzisa i-laser cutter yeshidi le-acrylic enamandla kakhulusika, qopha, noma usikeumklamo phezu kocezu lwe-acrylic ecacile.

Ukusika okuwumphumela kunguihlanzekile futhi inembile, enonqenqema olupholishiwe oludinga ukucutshungulwa okuncane kwangemuva.

Kulesi sihloko, sizofaka izinyathelo eziyisisekelo zokusika i-acrylic ecacile ye-laser futhi sinikeze amathiphu namasu okukufundisaindlela yokusika i-acrylic ecacile nge-laser.

Uhlu Lokuqukethwe:

• Khetha I-Acrylic Ecacile Efanelekile

Ngaphandle kokuvikela i-acrylic ekunwambeni, ekukhetheni izinhlobo ze-acrylic, kunezinto ezithile okudingeka uziqaphele.

Siyazi ukuthi kunezinhlobo ezimbili zamashidi e-acrylic: i-acrylic ekhonjiwe kanye ne-acrylic extruded.

I-Cast acrylic ifaneleka kakhulu ukusika i-laser imbangela yokuqina kwayo kanye nomphetho ophucuziwe ngemuva kokusika.

Kodwa uma ukhathazekile ngezindleko, i-acrylic ekhishiwe ibiza kancane, ngokusebenzisa ukuhlolwa kwe-laser nokusetha okucophelela kwemingcele, ungathola i-laser-cut acrylic enhle kakhulu.

• Khomba Ukucaca Kweshidi Le-Acrylic

Ungakwazi ukubamba ishidi le-acrylic ekukhanyeni, ukuze ubone ukufiphala nokungapheleli. I-acrylic yekhwalithi ephezulu ecacile kufanele icace ngokucwebezelayo ngaphandle kwenkungu ebonakalayo noma ukushintsha kombala.

Noma ungathenga ngokuqondile ibanga elithile le-acrylic. Alebulwe njengebanga elicacile noma le-premium, ama-acrylic aklanyelwe ngokukhethekile izinhlelo zokusebenza lapho ukucaca kubalulekile.

• Gcina I-Acrylic Ihlanzekile

Ngaphambi kokusika i-acrylic ecacile nge-laser, kubalulekile ukwenza isiqiniseko sokuthi impahla injaloilungiswe kahle.

Amashidi e-acrylic acacile ngokuvamile afika nefilimu evikelayo nhlangothi zombili ukuvimbela imihuzuko nokulimala ngesikhathi sokuthutha nokuphatha.

Ukuze uthole i-acrylic ewugqinsi, kubalulekile ukususale filimu yokuzivikela iyadingekangaphambi kwe-CO2 laser acrylic cutting, njengoba kungabangelaukusika okungalingani kanye nokuncibilika.

Uma ifilimu yokuzivikela isusiwe, i-acrylic kufanele ihlanzwe nge-aokokuhlanza okuncaneukususa noma yikuphi ukungcola, uthuli, noma imfucumfucu.

• Khetha I-Acrylic Laser Cutter Efanelekayo

Uma i-acrylic ecacile isilungisiwe, sekuyisikhathi sokusetha umshini wokusika we-laser.

Umshini osika i-acrylic kufanele ufakwe i-CO2 laser enobude obungamazacishe 10.6 micrometers.

Khetha amandla e-laser nendawo yokusebenza ngokuya ngokujiya kwakho nosayizi we-acrylic.

Imvamisa, amafomethi okusebenza ajwayelekile emishini yokusika ye-acrylic laser ayiumsiki omncane we-acrylic laser 1300mm * 900mmfuthiumshini omkhulu wokusika we-acrylic laser 1300mm * 2500mm. Lokho kungahlangabezana nezidingo eziningi zokusika i-acrylic.

Uma unosayizi okhethekile we-acrylic nephethini yokusika, sicelaXhumana nathiukuthola isiphakamiso sochwepheshe. Ukwenza ngendlela oyifisayo osayizi bemishini nokulungiselelwa kuyatholakala.

• Ukulungisa Umshini futhi Thola Isilungiselelo Esikahle

I-laser kufanele futhi ilinganiswe emandleni alungile kanye nezilungiselelo zesivinini, ezingase zihluke kuye ngokuqina kwe-acrylic nokujula okufiswayo kokusika. Siphakamisa ukuhlola impahla yakho ngezinsalela ezithile kuqala.

I-laser kufanele igxile ebusweni be-acrylic ukuze kuqinisekiswe ukusika okunembile. Ungabuthola kanjani ubude bokugxila obufanele be-laser cutter yakho, hlolalaser okokufundisa, noma funda kuvidiyo engezansi.

Ngaphambi kokuqala inqubo yokusika i-CO2 laser acrylic, kubalulekile ukuklama iphethini yokusika.

Lokhu kungenziwa kusetshenziswa isoftware ye-computer-aid design (CAD) efanaI-Adobe Illustrator noma i-AutoCAD.

Iphethini yokusika kufanele igcinwenjengefayela le-vector, engalayishwa emshinini wokusika we-laser ukuze icutshungulwe.

Iphethini yokusika kufanele futhi ifakenoma yimiphi imiklamo eqoshiwe noma e-etching efiswayo.

Lapho i-laser yokusika i-acrylic isimisiwe futhi iphethini yokusika yaklanywa, sekuyisikhathi sokuqala inqubo yokusika i-CO2 laser acrylic.

I-acrylic ecacile kufanele ibekwe ngokuphepha embhedeni wokusika womshini,ukuqinisekisa ukuthi isezingeni futhi iphansi.

I-laser cutter acrylic sheets kufanele ivulwe, futhi iphethini yokusika kufanele ilayishwe emshinini.

Umshini wokusika we-laser uzolandela iphethini yokusika, usebenzisa i-laser ukusika i-acrylic ngokunemba nokunemba.

Ividiyo: I-Laser Cut & Uqophe Ishidi Le-Acrylic

• Sebenzisa Isilungiselelo Samandla Aphansi

Sula i-acrylic canncibilika futhi ushintshe umbalakuzilungiselelo zamandla aphezulu.

Ukuze ugweme lokhu, kungcono ukusebenzisaukulungiselelwa kwamandla aphansifuthiyenza amaphasi amaningiukufeza ukujula okufunayo kokusika.

• Sebenzisa i-High-Speed Setting

Sula i-acrylic can futhiqhekezakuzilungiselelo zesivinini esiphansi.

Ukuze ugweme lokhu, kungcono ukusebenzisa aukusetha ngesivinini esikhulu futhi wenze amaphasi amaningiukufeza ukujula okufunayo kokusika.

• Sebenzisa Umthombo Womoya Ocindezelwe

Umthombo womoya ocindezelwe ungasiza ukuphephula udoti futhi uvimbele ukuncibilika phakathi nenqubo yokusika i-laser.

• Sebenzisa Umbhede Wokusika Izinyosi

Umbhede wokusika ikhekheba lezinyosi ungasiza ukusekela i-acrylic ecacile futhi uvimbele ukulwa phakathi nenqubo yokusika i-laser.

• Sebenzisa i-Masking Tape

Ukusebenzisa i-masking tape ebusweni be-acrylic ecacile ngaphambi kokusika kwe-laser kungasiza ekuvimbeleni ukuguga nokuncibilika.

I-Laser yokusika i-acrylic ecacile iyinqubo eqondile engenziwa ngokunemba nokunemba kusetshenziswa imishini namasu afanele. Ngokulandela izinyathelo ezichazwe kulesi sihloko nokusebenzisa amathiphu namasu anikeziwe, ungafinyelela imiphumela engcono kakhulu lapho usika i-acrylic ecacile ye-laser yephrojekthi yakho elandelayo.

Ukuze uqophe i-acrylic nge-laser, qala ngokuqinisekisa ukuthi ishidi le-acrylic lihlanzekile futhi ugcine ifilimu evikelayo ivuliwe. Misa i-laser cutter ngokugxilisa i-laser nokukhetha amandla afanele, isivinini, nezilungiselelo zokuvama kohlobo lwe-acrylic nogqinsi.Sebenzisa isofthiwe ye-graphic design design ukuze udale umklamo wakho wokuqopha futhi uwuguqule ube yifomethi ehambisanayo. Beka futhi uvikele ishidi le-acrylic kusikwa se-laser bese uqapha inqubo yokusika embhedeni we-laser bese uqapha i-laser cutter.

Ukusika i-acrylic ecacile, i-laser ye-CO2 iwuhlobo olufaneleka kakhulu. Ama-lasers we-CO2 asebenza kahle kakhulu ekusikeni nasekuqopheni i-acrylic ngenxa yobude bawo obukhethekile (ama-micrometer angu-10.6), amuncwa kahle izinto ezibonakalayo.Ngohlelo olukhulu lokungenisa umoya, nokunemba okuphezulu kokusika, umshini wokusika we-CO2 laser uyakwazi ukusika nokuqopha amashidi e-acrylic ahlanzekile anomumo ohlanzekile wokusika.

Yebo, ungakwazi ukusika i-acrylic ecacile nge-laser.

Ama-Laser cutters afaneleka kahle ukusika i-acrylic ngenxa yokunemba kwawo kanye nekhono lokudala imiphetho ehlanzekile, ebushelelezi.I-acrylic ye-Cast kanye ne-acrylic extruded ingasikwa nge-laser futhi iqoshwe.Ngenxa yokunemba nokucutshungulwa kokushisa, i-laser-cut acrylic inomphetho opholishiwe nohlanzekile, ngamaphethini wokusika angokwezifiso.

Ividiyo: Enza ngendlela oyifisayo Isibonisi se-LED nge-Laser Engraving Acrylic

I-Laser Cut Acrylic Signage

I-Laser Cut Thick Acrylic ifika ku-21mm

Okokufundisa: I-Laser Cut & Uqophe ku-Acrylic

Thatha Imibono Yakho, Woza ne-Laser Acrylic ukuze Ujabule!

I-Laser Cut Ephrintiwe Acrylic? Kulungile!

Hhayi kuphela ukusika amashidi e-acrylic acacile, i-CO2 Laser ingasika i-acrylic ephrintiwe. Ngosizo lweIkhamera ye-CCD, i-acrylic laser cutter izwa sengathi inamehlo, futhi iqondise ikhanda le-laser ukuthi linyakaze futhi lisike eduze komkhonto ophrintiwe. Funda kabanzi mayelanaIkhamera ye-CCD laser cutter >>

I-acrylic ephrintiwe nge-UVngemibala ecebile namaphethini kancane kancane itholakala endaweni yonke, yengeza ukuguquguquka okwengeziwe nokwenza ngokwezifiso.Kuyamangaza,futhi ingasikwa nge-laser ngokunembile ngephethini ye-Optical Recognition Systems.Amabhodi okukhangisa, imihlobiso yansuku zonke, ngisho nezipho ezikhumbulekayo ezenziwe nge-acrylic ephrintiwe isithombe, esekelwa ukuphrinta nobuchwepheshe bokusika i-laser, kulula ukuyifinyelela ngesivinini esikhulu nokwenza ngokwezifiso. Ungakwazi ukusika i-acrylic ephrintiwe nge-laser njengomklamo wakho owenziwe ngokwezifiso, okahle futhi osebenza kahle kakhulu.

1. Izimpawu Nezibonisi

Izimpawu Zokuthengisa:I-Laser-cut acrylic ivame ukusetshenziselwa ukudala izinga eliphezulu, izimpawu ezibonakalayo ezikhangayo ezitolo ezithengisayo, ezinikeza ukubukeka okubushelelezi nobungcweti.

Imibukiso yezohwebo:Umumo nemiklamo yangokwezifiso ingafinyelelwa kalula, iyenze ilungele ukudala amadokodo nemibukiso yohwebo edonsa amehlo nezibonisi.

Izimpawu zokuthola indlela:Ihlala isikhathi eside futhi imelana nesimo sezulu, i-laser-cut acrylic ilungele izimpawu eziqondisayo zangaphakathi nangaphandle.

2. I-Interior Design kanye ne-Architecture

I-Wall Art namaphaneli:Imiklamo eyinkimbinkimbi namaphethini angasikwa nge-laser abe amashidi e-acrylic, awenze aphelele kumaphaneli odonga okuhlobisa kanye nokufakwa kobuciko.

Izinto zokulungisa izibani:Izakhiwo ezihlukanisa ukukhanya ze-Acrylic zikwenza kube yisinqumo esihle kakhulu sokudala izibani zesimanje nezembozo zezibani.

3. Ifenisha kanye Nokuhlobisa Kwasekhaya

Amathebula Nezihlalo:Ukuguquguquka kokusika kwe-laser kuvumela ukuthi kudalwe izingcezu zefenisha ye-acrylic yangokwezifiso enemiklamo eyinkimbinkimbi nemiphetho ebushelelezi.

Izimpawu Zokuhlobisa:Kusukela kumafreyimu ezithombe kuya kuzingcezu zokuhlobisa, i-laser-cut acrylic ingangeza ukuthinta kobuhle kunoma yikuphi ukuhlobisa ekhaya.

4. Izicelo Zezokwelapha Nezesayensi

Izindlu Zempahla Yezokwelapha:I-Acrylic isetshenziselwa ukwakha izindlu ezicacile, eziqinile zemishini yezokwelapha neyelabhorethri.

Ama-Prototypes namamodeli:I-Laser-cut acrylic ilungele ukukhiqiza ama-prototypes anembayo namamodeli ocwaningo lwesayensi nentuthuko.

5. Izimoto kanye ne-Aerospace

Izingxenye zedeshibhodi:Ukunemba kokusika kwe-laser kuyenza ifaneleke ukukhiqiza izingxenye ze-acrylic zamadeshibhodi ezimoto namaphaneli okulawula.

Izingxenye ze-Aerodynamic:I-Acrylic isetshenziselwa ukudala izingxenye ezingasindi, ezisebenza kahle emoyeni zezimoto nezindiza.

6. Art and Jewelry

Ubucwebe bangokwezifiso:I-laser-cut acrylic ingasetshenziselwa ukwakha izingcezu zobucwebe eziyingqayizivele, ezenziwe ngezifiso ezinemiklamo eyinkimbinkimbi.

Izingxenye Zobuciko:Amaciko asebenzisa i-laser-cut acrylic ukukhiqiza izithombe eziqoshiwe ezinemininingwane namaphrojekthi obuciko obuxube bemidiya.

7. Ukwenza Izibonelo

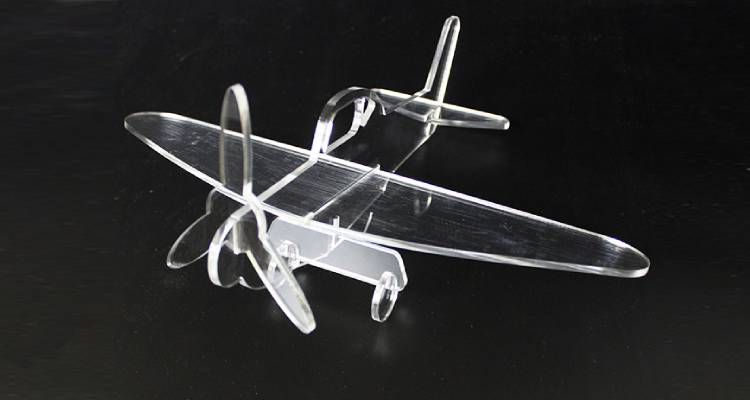

Amamodeli Ezakhiwo:Abadwebi bezakhiwo nabaklami basebenzisa i-laser-cut acrylic ukuze bakhe amamodeli esikali anemininingwane nanembile ezakhiwo nezindawo.

Amamodeli wokuzilibazisa:Abathanda ukuzilibazisa basebenzisa i-laser-cut acrylic ukuze benze izingxenye zemodeli yezitimela, izindiza, nezinye izifaniso ezincane.

8. Izimboni kanye Nezokukhiqiza

Iziqaphi zomshini namakhava:I-Acrylic isetshenziselwa ukwenza onogada abavikelayo kanye nesembozo semishini, enikeza ukubonakala nokuphepha.

I-Prototyping:Ekwakhiweni kwezimboni, i-laser-cut acrylic ivame ukusetshenziselwa ukudala ama-prototypes anembile kanye nezingxenye.

Noma yimiphi imibuzo mayelana nokusebenza kwe-Laser Cut Acrylic?

Isikhathi sokuthumela: Mar-16-2023