ISANDULELA SOKUSIKA LASER

Kukhona izinhlelo zokusebenza ze-laser ezihlukene kusukela kupeni le-laser okokufundisa ukuya ezikhalini ze-laser zesiteleka sebanga elide. I-Laser Cutting, njengokuhlukaniswa iziqephu kwezicelo, iye yathuthukiswa futhi igqama ekusikeni nasekuqopheni amasimu. Ngezici ezinhle kakhulu ze-laser, ukusebenza okuvelele kokusika, nokucubungula okuzenzakalelayo, imishini yokusika i-laser ithatha indawo yamathuluzi okusika endabuko. I-CO2 Laser iyindlela yokucubungula ethandwa kakhulu. Ubude begagasi obungu-10.6μm buhambisana cishe nazo zonke izinto ezingezona ezensimbi kanye nensimbi elaminate. Kusuka kwendwangu yansuku zonke nesikhumba, kuya epulasitiki esetshenziswa yizimboni, ingilazi, kanye ne-insulation, kanye nezinto zokwakha ezifana nokhuni ne-acrylic, umshini wokusika we-laser uyakwazi ukuphatha lezi futhi uqaphela imiphumela emihle kakhulu yokusika. Ngakho-ke, kungakhathaliseki ukuthi usebenza ngezinto zokusika nokuqopha ukuze kusetshenziswe ezentengiselwano nezimboni, noma ufuna ukutshala imali emshinini omusha wokusika wokuzilibazisa nomsebenzi wesipho, ukuba nolwazi oluncane lokusika i-laser kanye nomshini wokusika we-laser kuyoba usizo olukhulu kuwe ukwenza uhlelo.

UBUCHWEPHESHE

1. Uyini Umshini Wokusika I-Laser?

I-Laser Cutting Machine ingumshini onamandla wokusika nokuqopha olawulwa uhlelo lwe-CNC. I-laser beam esheshayo futhi enamandla isuka eshubhu le-laser lapho kwenzeka khona ukusabela komlingo wesithombe sikagesi. Amashubhu e-laser e-CO2 Laser Cutting ahlukaniswe abe izinhlobo ezimbili: amashubhu e-laser engilazi kanye namashubhu e-laser ensimbi. I-laser beam ekhishiwe izodluliswa ezintweni ozosikwa ngezibuko ezintathu nelensi eyodwa. Akukho ukucindezeleka komshini, futhi akukho ukuxhumana phakathi kwekhanda le-laser nezinto ezibonakalayo. Lapho i-laser beam ethwele ukushisa okukhulu idlula ezintweni, iyahwamuka noma ifakwe ngaphansi kwe-sublimated. Akukho lutho olusele ngaphandle kwe-kerf enhle ezacile endabeni. Lena inqubo eyisisekelo kanye nesimiso CO2 laser cutting. I-laser beam enamandla ifanelana nesistimu ye-CNC kanye nesakhiwo sokuthutha esiyinkimbinkimbi, futhi umshini wokusika we-laser oyisisekelo wakhiwe kahle ukuze usebenze. Ukuqinisekisa ukusebenza okuzinzile, ikhwalithi yokusika ephelele, nokukhiqizwa okuphephile, umshini wokusika we-laser ufakwe uhlelo lokusiza komoya, i-exhaust fan, idivayisi yokuvala, nokunye.

2. Isebenza Kanjani I-Laser Cutter?

Siyazi ukuthi i-laser isebenzisa ukushisa okukhulu ukusika izinto. Khona-ke ubani othumela umyalo wokuqondisa indlela ehambayo nendlela yokusika? Yebo, iwuhlelo oluhlakaniphile lwe-cnc laser oluhlanganisa isofthiwe yokusika i-laser, ibhodi elikhulu lokulawula, uhlelo lwesekethe. Isistimu yokulawula ezenzakalelayo yenza ukusebenza kube lula futhi kube lula, noma ngabe ungumuntu osaqalayo noma uchwepheshe. Sidinga nje ukungenisa ifayela lokusika bese sibeka imingcele ye-laser efanele njengejubane namandla, futhi umshini wokusika we-laser uzoqala inqubo yokusika elandelayo ngokusho kwemiyalelo yethu. Yonke inqubo yokusika nokuqopha nge-laser iyahambisana futhi inonemba okuphindaphindiwe. Akumangalisi ukuthi i-laser ingumpetha wejubane nekhwalithi.

3. Laser Cutter Isakhiwo

Ngokuvamile, umshini wokusika i-laser uqukethe izingxenye ezine eziyinhloko: indawo yokukhipha i-laser, uhlelo lokulawula, uhlelo lokunyakaza, kanye nesistimu yokuphepha. Yonke ingxenye idlala indima ebalulekile ekusikeni nasekuqopheni okunembayo nokusheshayo. Ukwazi ngezinye izakhiwo kanye nezingxenye zemishini yokusika i-laser, akusizi nje kuphela ukuthi wenze isinqumo esifanele lapho ukhetha futhi uthenga umshini, kodwa futhi kunikeza ukuguquguquka okwengeziwe kokusebenza kanye nokwandiswa kokukhiqizwa kwesikhathi esizayo.

Nasi isingeniso sezingxenye eziyinhloko zomshini wokusika i-laser:

Umthombo we-Laser:

I-CO2 Laser:Isebenzisa ingxube yegesi ngokuyinhloko eyakhiwe yi-carbon dioxide, iyenze ibe ilungele ukusika izinto ezingezona ezensimbi njengokhuni, i-acrylic, indwangu, nezinhlobo ezithile zamatshe. Isebenza ku-wavelength cishe ama-micrometer angu-10.6.

I-Fiber Laser:Isebenzisa ubuchwepheshe be-laser yesimo esiqinile esinama-optical fibers ahlanganiswe nezinto ezingavamile zomhlaba njenge-ytterbium. Isebenza kahle kakhulu ekusikeni izinsimbi njengensimbi, i-aluminium, nethusi, esebenza kubude begagasi obuzungeze ama-micrometer angu-1.06.

Nd:YAG Laser:Isebenzisa ikristalu ye-neodymium-doped yttrium aluminium garnet. Iguquguquka futhi ingakwazi ukusika kokubili izinsimbi nezinye okungezona izinsimbi, nakuba ingavamile kune-CO2 nama-laser we-fiber wokusika izinhlelo zokusebenza.

I-Laser Tube:

Ikha i-laser medium (igesi ye-CO2, esimweni samalaser e-CO2) futhi ikhiqiza i-laser beam ngokusebenzisa i-excitation kagesi. Ubude namandla eshubhu ye-laser kunquma amandla okusika kanye nobukhulu bezinto ezingasikwa. Kunezinhlobo ezimbili ze-laser tube: ingilazi laser tube kanye metal laser tube. Izinzuzo zamashubhu engilazi engilazi avumelana nesabelomali futhi angakwazi ukusika izinto ezilula phakathi kwebanga elithile elinembayo. Izinzuzo zamashubhu e-laser ensimbi isikhathi eside senkonzo kanye nekhono lokukhiqiza ukunemba okuphezulu kokusika kwe-laser.

Isistimu yokubona:

Izibuko:Ibekwe ngendlela efanele ukuze iqondise i-laser beam isuka kushubhu ye-laser iye ekhanda lokusika. Kufanele ziqondaniswe ngokunembile ukuze kuqinisekiswe ukulethwa okunembile kwemishayo.

Amalensi:Gxilisa i-laser beam endaweni enhle, uthuthukise ukunemba kokusika. Ubude bokugxila belensi buthinta ukugxila kwe-beam nokujula kokusika.

Ikhanda lokusika i-Laser:

Ilensi yokugxila:Iguqula i-laser beam ibe indawo encane yokusika okunembile.

Umbhobho:Iziqondiso zisiza amagesi (njenge-oxygen noma i-nitrogen) endaweni yokusika ukuze kuthuthukiswe ukusebenza kahle kokusika, ukuthuthukisa ikhwalithi yokusika, nokuvimbela ukunqwabelana kwemfucumfucu.

Inzwa yobude:Igcina ibanga elingaguquki phakathi kwekhanda lokusika nezinto ezibonakalayo, iqinisekisa ikhwalithi yokusika iyunifomu.

Isilawuli se-CNC:

I-Computer Numerical Control (CNC) System: Ilawula ukusebenza komshini, okuhlanganisa ukunyakaza, amandla e-laser, nesivinini sokusika. Ihumusha ifayela lokuklama (imvamisa nge-DXF noma amafomethi afanayo) futhi ilihumushele ekunyakazeni okunembayo nezenzo ze-laser.

Ithebula Lokusebenza:

Ithebula le-Shuttle:Ithebula le-shuttle, elibizwa nangokuthi i-pallet changer, lakhiwe ngomklamo wokudlula ukuze lithuthwe ngezindlela ezimbili. Ukuze kube lula ukulayishwa nokukhishwa kwezinto ezinganciphisa noma ziqede ukuphumula futhi zihlangabezane nokusika kwakho kwezinto ezithile, siklame osayizi abahlukahlukene ukuze bafanele wonke usayizi owodwa wemishini yokusika i-MimoWork laser.

I-Honeycomb Laser Bed:Ihlinzeka ngendawo eyisicaba futhi ezinzile enendawo encane yokuxhumana, inciphisa ukubukeka kwangemuva futhi ivumele ukusikeka okuhlanzekile. Umbhede we-laser wezinyosi uvumela ukungena komoya okulula kokushisa, uthuli, nentuthu ngesikhathi senqubo yokusika i-laser.

Ithebula le-Knife Strip:Ikakhulukazi okokusika ezintweni eziwugqinsi lapho ungathanda ukugwema ukubhampa kwe-laser. Amabha aqondile avumela futhi ukugeleza kwe-exhaust engcono kakhulu ngenkathi usika. I-Lamellas ingafakwa ngabanye, ngenxa yalokho, ithebula le-laser lingalungiswa ngokuvumelana nesicelo ngasinye somuntu ngamunye.

Ithebula le-Conveyor:Ithebula le-conveyor lenziwe ngaloinsimbi engagqwali webokuyifaneleizinto ezincane nezivumelana nezimo ezifanaifilimu,indwangufuthiisikhumba.Ngesistimu yokuthutha, ukusika kwe-laser okungapheli sekuyenzeka. Ukusebenza kahle kwezinhlelo ze-laser ze-MimoWork kungandiswa futhi.

Ithebula le-Acrylic Cutting Grid:Kubandakanya ithebula lokusika le-laser elinegridi, igridi ekhethekile ye-laser engraver ivimbela ukubuyiswa emuva. Ngakho-ke ilungele ukusika ama-acrylic, ama-laminates, noma amafilimu epulasitiki anezingxenye ezincane kuno-100 mm, njengoba lezi zihlala endaweni eyisicaba ngemva kokusikwa.

Phina Ithebula Lokusebenza:Iqukethe izikhonkwane eziningi ezilungisekayo ezingahlelwa ngokulungiselelwa okuhlukahlukene ukuze kusekelwe okokusebenza okusikwayo. Lo mklamo unciphisa ukuthintana phakathi kwezinto ezibonakalayo nendawo yokusebenza, unikeze izinzuzo ezimbalwa zokusika kwe-laser nokuqopha izinhlelo zokusebenza.

Uhlelo Lokunyakaza:

I-Stepper Motors noma i-Servo Motors:Shayela u-X, Y, futhi ngezinye izikhathi ukunyakaza kwe-Z-axis kwekhanda elisikayo. Ama-Servo motors ngokuvamile anembe kakhulu futhi ayashesha kunama-stepper motors.

Imihlahlandlela Yemigqa Nomzila:Qinisekisa ukunyakaza okubushelelezi nokunembe kwekhanda lokusika. Zibalulekile ekugcineni ukunemba kokusika nokungaguquguquki isikhathi eside.

Uhlelo Lokupholisa:

I-Water Chiller: Igcina ishubhu le-laser nezinye izingxenye ezingeni lokushisa elilungile ukuvimbela ukushisa ngokweqile nokugcina ukusebenza okungaguquki.

Usizo Lomoya:Ivuthela umoya ngombhobho ukuze isuse imfucumfucu, inciphise izindawo ezithinteke ukushisa, futhi ithuthukise ikhwalithi yokusika.

I-Exhaust System:

Susa intuthu, intuthu, kanye nezinhlayiyana ezikhiqizwe ngesikhathi sokusika, uqinisekise indawo yokusebenza ehlanzekile nephephile. Ukungena komoya ngendlela efanele kubalulekile ukuze kugcinwe izinga lomoya nokuvikela kokubili umqhubi nomshini.

Iphaneli yokulawula:

Inikeza opharetha isixhumi esibonakalayo sokufaka izilungiselelo, baqaphe isimo somshini, futhi balawule inqubo yokusika. Ingase ihlanganise isibonisi sesikrini esithintwayo, inkinobho yokumisa isimo esiphuthumayo, nezinketho zokulawula mathupha zokulungiswa okuhle.

Izici zokuphepha:

Idivayisi Yezibiyelo:Vikela opharetha ekuchayekeni kwe-laser kanye nemfucumfucu engaba khona. Okuvalekile kuvame ukukhiywa ukuze kuvalwe i-laser uma kuvulwa ngesikhathi sokusebenza.

Inkinobho Yokumisa Isimo Esiphuthumayo:Ivumela ukuvala shaqa ngokushesha komshini esimweni esiphuthumayo, iqinisekisa ukuphepha komsebenzisi.

Izinzwa Zokuphepha Ze-Laser:Thola noma yikuphi okudidayo noma izimo ezingaphephile, okubangela ukuvala shaqa okuzenzakalelayo noma izexwayiso.

Isoftware:

Isoftware yokusika i-Laser: I-MimoCUT, isofthiwe yokusika i-laser, yakhelwe ukwenza lula umsebenzi wakho wokusika. Vele ulayishe amafayela akho e-laser cut vector. I-MimoCUT izohumusha imigqa echaziwe, amaphuzu, amajika, nomumo iye olimini lokuhlela elingabonwa isofthiwe ye-laser cutter, futhi iqondise umshini we-laser ukuze uqalise.

Isofthiwe ye-Auto-Nest:I-MimoNEST, isofthiwe yokusika izidleke nge-laser isiza abakhi bempahla ukuthi banciphise izindleko zezinto futhi bathuthukise izinga lokusetshenziswa kwezinto ngokusebenzisa ama-algorithms athuthukisiwe ahlaziya ukuhluka kwezingxenye. Ngamagama alula, ingabeka amafayela okusika i-laser kundaba ngokuphelele. Isofthiwe yethu yokwenza isidleke yokusika i-laser ingasetshenziselwa ukusika izinto ezihlukahlukene njengezakhiwo ezinengqondo.

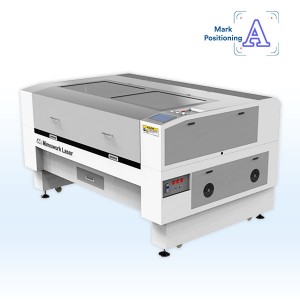

Isofthiwe Yokubona Ikhamera:I-MimoWork iyathuthuka Ikhamera ye-CCD ye-Laser Positioning System engabona futhi ithole izindawo zesici ukukusiza ukuthi wonge isikhathi futhi ukhulise ukunemba kokusika kwe-laser ngasikhathi sinye. Ikhamera ye-CCD ifakwe eduze kwekhanda le-laser ukucinga ucezu lokusebenza usebenzisa izimpawu zokubhalisa ekuqaleni kwenqubo yokusika. Ngale ndlela, amamaki efiducial aphrintiwe, alukiweyo futhi ahlotshisiwe kanye namanye amakhonsathi anomehluko ophezulu angaskenwa ngokubonakalayo ukuze ikhamera ye-laser cutter yazi ukuthi ukuphi ubungako bangempela bezingcezu zomsebenzi, kuzuzwe umklamo onembile wokusika i-laser.

I-Projection Software:Ngo- Isoftware yeMimo Projection, uhlaka kanye nesimo sezinto ezizosikwa kuzoboniswa etafuleni lokusebenza, okusiza ukulinganisa indawo enembile yekhwalithi ephakeme yokusika i-laser. Ngokuvamile i-Izicathulo noma IzicathuloUkusika kwe-laser sebenzisa idivayisi yokubonisa. Njenge Isikhumba sangempela izicathulo, pu lesikhumba izicathulo, ukunitha phezulu, amateki.

I-Prototype Software:Ngokusebenzisa ikhamera ye-HD noma isithwebuli sedijithali, I-MimoPROTOTYPE ibona ngokuzenzakalelayo uhlaka nemicibisholo yokuthunga yesiqeshana sezinto ezibonakalayo futhi ikhiqize amafayela omklamo ongawangenisa kusofthiwe yakho ye-CAD ngokuqondile. Uma kuqhathaniswa nephuzu lokulinganisa lemanuwali lendabuko ngephuzu, ukusebenza kahle kwesofthiwe ye-prototype ephakeme izikhathi eziningana. Udinga kuphela ukubeka amasampula okusika etafuleni lokusebenza.

Amagesi Wokusiza:

Umoya-mpilo:Ithuthukisa isivinini sokusika kanye nekhwalithi yezinsimbi ngokwenza lula ukusabela kwe-exothermic, okufaka ukushisa enqubweni yokusika.

I-nitrogen:Isetshenziselwa ukusika okungezona izinsimbi nezinye izinsimbi ukufeza ukusikeka okuhlanzekile ngaphandle kwe-oxidation.

Umoya Ocindezelwe:Isetshenziselwa ukusika okungezona izinsimbi ukuze kukhishwe izinto ezincibilikisiwe futhi kuvimbele ukuvutha.

Lezi zingxenye zisebenza ngokuvumelana ukuze kuqinisekiswe ukusebenza kwe-laser okunembile, ephumelelayo, futhi ephephile yokusika izinto ezihlukahlukene, okwenza imishini yokusika i-laser ibe namathuluzi ahlukahlukene ekukhiqizeni nasekukhiqizeni kwesimanje.

Imisebenzi eminingi kanye nokuguquguquka kwekhamera ye-laser cutter ngokushesha ukusika ilebula elukiwe, isitika, nefilimu enamathelayo iye ezingeni eliphezulu ngokusebenza kahle okuphezulu nokunemba okuphezulu. Amaphethini wokuphrinta nokufekethiswa esichibini kanye nelebula elukiweyo adinga ukusikwa ngokunembile...

Ukuze kuhlangatshezwane nezidingo zebhizinisi elincane, kanye nomklamo wangokwezifiso, i-MimoWork yaklama isisiki se-laser esihlangene esinosayizi wedeskithophu ongu-600mm * 400mm. Ikhamera ye-laser cutter ifanele ukusika isichibi, ukufekethisa, isitika, ilebula, kanye ne-applique esetshenziswa engutsheni nasezintweni...

I-contour laser cutter 90, ebizwa nangokuthi i-CCD laser cutter iza nosayizi womshini ongu-900mm * 600mm kanye nomklamo we-laser ovalwe ngokugcwele ukuze kuqinisekiswe ukuphepha okuphelele, ikakhulukazi kwabaqalayo. Ngekhamera ye-CCD efakwe eceleni kwekhanda le-laser, noma iyiphi iphethini nomumo...

Iklanyelwe Ngokukhethekile Imboni Yezimpawu Nefenisha, Bopha Amandla Obuchwepheshe Bekhamera Ye-CCD Ethuthukisiwe Ukuze Usike Ngokuphelele Iphethini Ephrintiwe Ye-Acrylic Ephrintiwe. Ngokudluliswa kwe-Ball Screw Transmission kanye Nezinketho Zezimoto Ze-Servo Ezinemba Kakhulu, Gxila Ekunembeni Okungafaniswe kanye...

Izwa i-Cutting-Edge Fusion of Art and Technology nge-Mimowork's Printed Wood Laser Cutter. Vula Umhlaba Wamathuba Njengoba Usika Ngokungenamthungo futhi Uqopha Ukhuni kanye Nendalo Yokhuni Ephrintiwe. Iklanyelwe Imboni Yezimpawu Nefenisha, Isisiki Sethu Se-Laser Sisebenzisa I-CCD Ethuthukisiwe...

Ifaka ikhamera ye-HD yesimanje ebekwe phezulu, ibona kalula amakhonsathi futhi idlulisele idatha yephethini ngokuqondile emshinini wokusika izindwangu. Valelisa ezindleleni zokusika eziyinkimbinkimbi, njengoba lobu buchwepheshe bunikeza isisombululo esilula nesinembe kakhulu seleyisi kanye...

Kwethulwa umshini wezingubo zezemidlalo we-Laser Cut (160L) - isisombululo esiphezulu sokusikwa kwe-sublimation kadayi. Ngekhamera yayo ye-HD entsha, lo mshini ungathola ngokunembile futhi udlulise idatha yephethini ngokuqondile emshinini wokusika iphethini yendwangu. Iphakethe lethu lesoftware linikeza izinhlobonhlobo zezinketho..

Sethula i-Sublimation Polyester Laser Cutter eshintsha igeyimu (180L) – isixazululo esiphezulu sokusika izindwangu ze-sublimation ngokunemba okungenakuqhathaniswa. Ngosayizi wetafula wokusebenza ovulekile ongu-1800mm*1300mm, lesi sisiki senzelwe ukucubungula i-polyester ephrintiwe...

Ngena ezweni eliphephile, elihlanzekile, nelinembe kakhudlwana lokusika indwangu ye-sublimation ngomshini wezingubo zezemidlalo we-Laser Cut (Ovalelwe Ngokugcwele). Isakhiwo sayo esivaliwe sinikeza izinzuzo eziphindwe kathathu: ukuphepha okuthuthukisiwe komsebenzisi, ukulawula uthuli okuphakeme, kanye...

Ukuze kuhlangatshezwane nezidingo zokusika zendwangu enkulu futhi ebanzi yomqulu, i-MimoWork idizayine i-ultra-wide format sublimation laser cutter nge-CCD Camera ukusiza ukusika izindwangu eziphrintiwe njengezibhengezo, amafulegi ezinyembezi, izimpawu, isibonisi sombukiso, isibonisi sombukiso, njll. 3200mm * 1400mm wendawo yokusebenza...

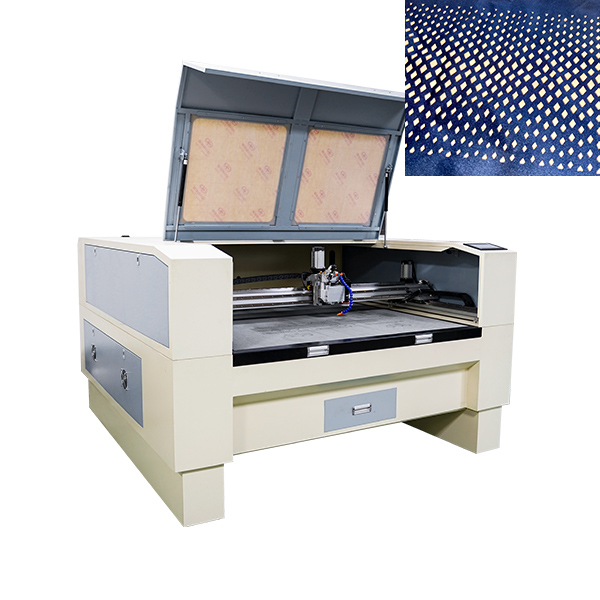

I-Contour Laser Cutter 160 ifakwe ikhamera ye-CCD elungele ukucubungula izinhlamvu ze-twill ezinembayo, izinombolo, amalebula, izesekeli zokugqoka, izindwangu zasekhaya. Umshini wokusika i-laser yekhamera uvakashela isofthiwe yekhamera ukuze ubone izindawo zesici futhi wenze ukusika kwephethini okunembile...

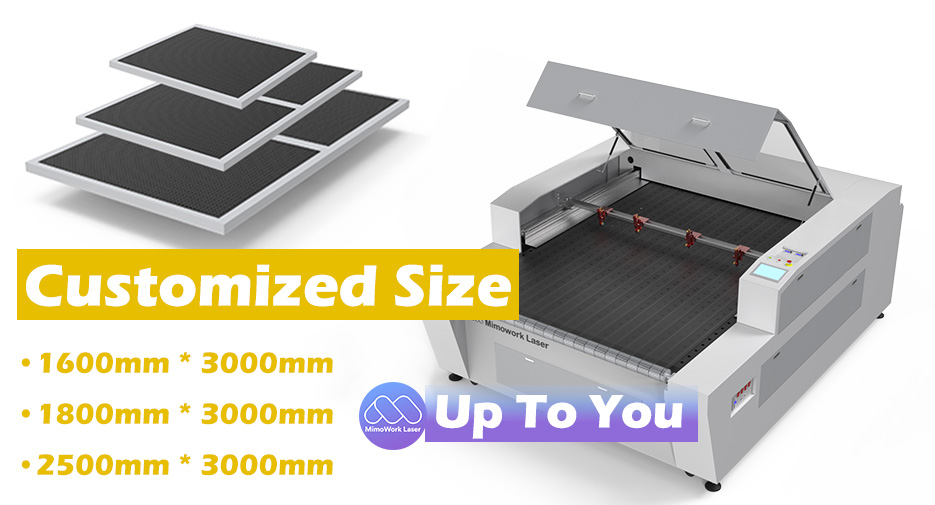

▷ Umshini Wokusika we-Flatbed Laser (Owenziwe ngokwezifiso)

Usayizi womshini ohlangene usindisa kakhulu isikhala futhi ungamukela izinto ezidlulela ngale kobubanzi obusikiwe ngomklamo wokungena onezindlela ezimbili. I-Mimowork's Flatbed Laser Engraver 100 yenzelwe ukuqopha nokusika izinto eziqinile nezinto eziguqukayo, njengokhuni, i-acrylic, iphepha, izindwangu...

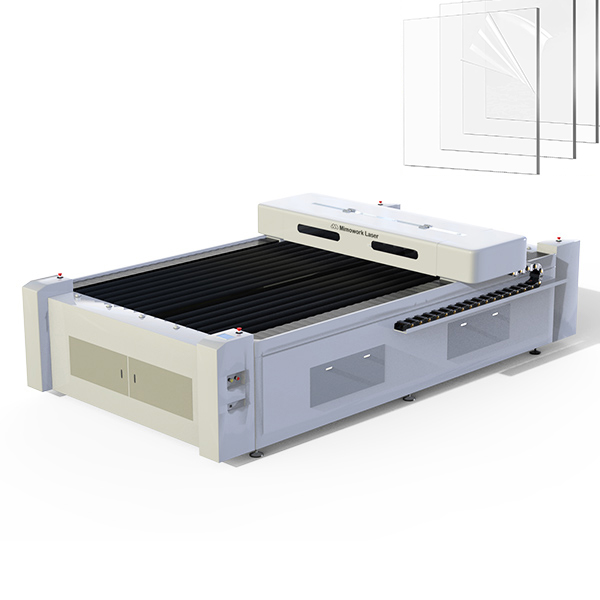

I-Wood Laser engraver engenziwa ngokwezifiso ngokugcwele izidingo zakho kanye nesabelomali. I-MimoWork's Flatbed Laser Cutter 130 ihloselwe ukuqopha nokusika izinkuni (i-plywood, i-MDF), ingasetshenziswa naku-acrylic nezinye izinto. Ukuqoshwa kwe-laser okuguquguqukayo kusiza ukufeza ukhuni lomuntu siqu ...

Umshini wokuqopha we-Acrylic Laser ongenziwa ngezifiso ngokugcwele izidingo zakho kanye nesabelomali. I-Mimowork's Flatbed Laser Cutter 130 ihloselwe ukuqopha nokusika i-acrylic (i-plexiglass/PMMA), ingasetshenziswa futhi okhunini nakwezinye izinto. Ukuqoshwa kwe-laser okuguquguqukayo kusiza uku...

Ilungele ukusika usayizi omkhulu namashidi okhuni awugqinsi ukuze kuhlangatshezwane nokukhangisa okuhlukahlukene kanye nezinhlelo zokusebenza zezimboni. Ithebula lokusika i-laser engu-1300mm * 2500mm lakhiwe ngendlela enezindlela ezine. Ebonakala ngesivinini esikhulu, umshini wethu wokusika we-CO2 wezinkuni we-laser ungafinyelela isivinini sokusika esingu-36,000mm ...

Ilungele ukusika i-laser usayizi omkhulu namashidi e-acrylic aminyene ukuze kuhlangatshezwane nezinhlelo zokusebenza ezihlukene zokukhangisa nezimboni. Ithebula lokusika i-laser engu-1300mm * 2500mm lakhiwe ngendlela enezindlela ezine. Amashidi we-acrylic wokusika i-laser asetshenziswa kabanzi embonini yokukhanyisa nokuhweba, emkhakheni wokwakha ...

Umshini we-laser ohlangene futhi omncane uthatha indawo encane futhi kulula ukuyisebenzisa. Ukusika nokuqopha nge-laser okuguquguqukayo kufanelana nalezi zimfuno zemakethe ezenziwe ngezifiso, ezigqama kakhulu emkhakheni wezobuciko bephepha. Ukusika amaphepha okuyinkimbinkimbi kumakhadi ezimemo, amakhadi okubingelela, izincwajana, i-scrapbooking, namakhadi ebhizinisi...

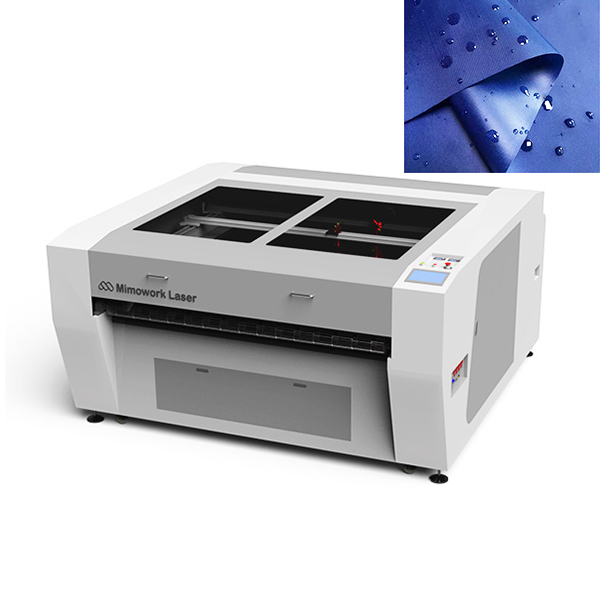

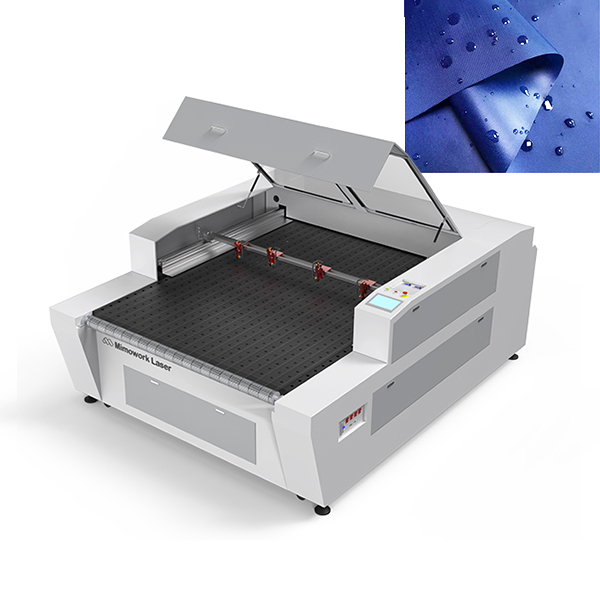

Ukufaka izingubo ezivamile nosayizi bezingubo, umshini wokusika indwangu we-laser unetafula elisebenzayo elingu-1600mm * 1000mm. Indwangu ye-soft roll ifaneleka kakhulu ukusika i-laser. Ngaphandle kokuthi, isikhumba, ifilimu, imizwa, idenim nezinye izingcezu zingasikwa nge-laser ngenxa yetafula lokusebenza ozikhethela lona...

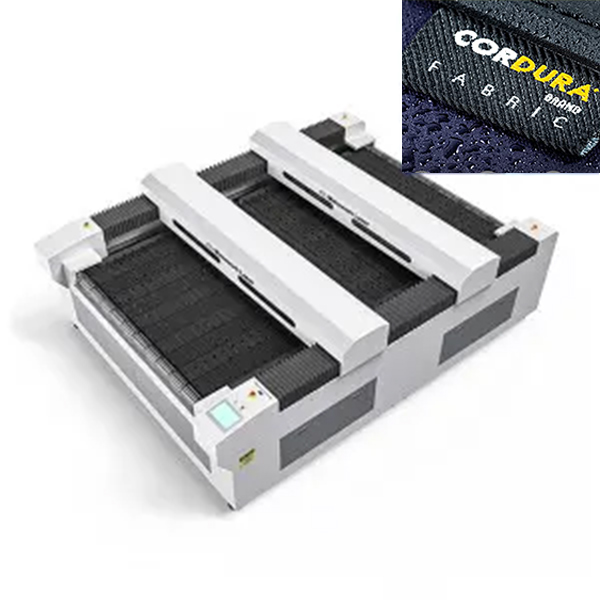

Ngokusekelwe kumandla aphezulu kanye nokuminyana kwe-Cordura, ukusika i-laser kuyindlela esebenza kahle kakhulu yokucubungula ikakhulukazi ukukhiqizwa kwezimboni kwe-PPE namagiya ezempi. Umshini wokusika indwangu ye-laser yezimboni ufakwe ngendawo enkulu yokusebenza ukuze uhlangabezane nefomethi enkulu ye-Cordura yokusika-njengenhlamvu yezinhlamvu...

Ukuze uhlangabezane nezinhlobo eziningi zezidingo zokusika zendwangu ngobukhulu obuhlukahlukene, i-MimoWork inweba umshini wokusika we-laser ube ngu-1800mm * 1000mm. Kuhlanganiswe netafula lokuhambisa, indwangu egoqekayo kanye nesikhumba kungavunyelwa ukudlulisa nokusika nge-laser kwemfashini nezindwangu ngaphandle kokuphazamiseka. Ngaphezu kwalokho, amakhanda e-laser amaningi...

Umshini Wokusika we-Laser Format Large wenzelwe izindwangu nezindwangu ezinde kakhulu. Ngetafula elisebenzayo elingamamitha angu-10 ubude nobubanzi obungamamitha angu-1.5, ifomethi ye-laser cutter enkulu ifanele amashidi amaningi endwangu namaroli njengetende, ipharashuti, i-kitesurfing, ukhaphethi wendiza, i-pelmet yokukhangisa nezimpawu, indwangu kaseyili nokunye...

Umshini wokusika we-CO2 we-laser ufakwe isistimu ye-projektha enomsebenzi onembile wokumisa. Ukubuka kuqala kwe-workpiece okufanele isikwe noma iqoshwe kukusiza ukuthi ubeke impahla endaweni efanele, okwenza ukusika kwe-post-laser nokuqoshwa kwe-laser kuhambe kahle nangokunemba okuphezulu...

Umshini we-Laser we-Galvo (Sika futhi Uqophe futhi Ugqobhoze)

I-MimoWork Galvo Laser Marker ingumshini onezinjongo eziningi. Ukuqoshwa kwe-laser ephepheni, iphepha lokusika le-laser elenziwe ngokwezifiso kanye ne-perforating yephepha konke kungaqedwa ngomshini we-galvo laser. I-Galvo laser beam enokunemba okuphezulu, ukuguquguquka, kanye nesivinini sombani kudala ngokwezifiso ...

I-laser beam endizayo isuka ku-engeli yelensi eguquguqukayo ingabona ukucubungula okusheshayo ngaphakathi kwesikali esichaziwe. Ungalungisa ubude bekhanda le-laser ukuze ulingane nosayizi wento ecutshunguliwe. Ishubhu le-laser yensimbi ye-RF ihlinzeka ngokumaka okuphezulu okunembayo nendawo ecolisekileyo ye-laser ukuya ku-0.15mm, elingana nephethini eqoshiwe ye-laser eyinkimbinkimbi esikhumbeni...

Umshini we-laser we-Fly-Galvo ufakwe kuphela ishubhu ye-laser ye-CO2 kodwa ungahlinzeka kokubili ngendwangu ye-laser perforating kanye nokusika kwe-laser kwezingubo nezindwangu zezimboni. Ngetafula elisebenzayo elingu-1600mm * 1000mm, umshini we-laser wendwangu enezimbobo ungathwala izindwangu eziningi zamafomethi ahlukene, uqaphela izimbobo zokusika ze-laser ezingaguquki...

I-GALVO Laser Engraver 80 enomklamo ovalwe ngokuphelele iyinketho yakho ephelele yokuqoshwa kwe-laser yezimboni nokumaka. Ngenxa yokubuka kwayo okukhulu kwe-GALVO okungu-800mm * 800mm, ilungele ukuqoshwa kwe-laser, ukumaka, ukusika, nokubhoboza isikhumba, ikhadi lephepha, i-vinyl yokudlulisa ukushisa, nanoma yiziphi ezinye izingcezu ezinkulu...

Umqophi we-laser wefomethi enkulu uyi-R&D yosayizi omkhulu wokuqoshwa kwe-laser nokumaka nge-laser. Ngesistimu yokuthutha, umqophi we-galvo laser angaqopha futhi amake ezindwangu ezigoqekayo (izindwangu). Ungawuthatha njengomshini wokuqopha we-laser wendwangu, umshini wokuqopha we-laser carpet, umqophi we-denim laser...

Isabelomali

Noma ngabe yimiphi imishini okhetha ukuyithenga, izindleko ezifaka inani lomshini, izindleko zokuthumela, ukufakwa, nezindleko zangemuva kokulungiswa kuhlale kucatshangelwa kuqala. Esigabeni sokuqala sokuthenga, unganquma izidingo zokusika ezibaluleke kakhulu zokukhiqiza kwakho ngaphakathi komkhawulo othile wesabelomali. Thola ukucushwa kwe-laser nezinketho zomshini we-laser ezihambisana nemisebenzi kanye nesabelomali. Ngaphandle kwalokho, udinga ukucabangela izindleko zokufaka nokusebenza, njengokuthi kunemali eyengeziwe yokuqeqesha, noma ukuqasha abasebenzi, njll. Lokho kukusiza ukuthi ukhethe umphakeli ofanelekayo wemishini ye-laser kanye nezinhlobo zemishini ngaphakathi kwesabelomali.

Izintengo zomshini wokusika we-laser ziyahlukahluka ngokuya ngezinhlobo zomshini, ukucushwa, kanye nezinketho. Sitshele izidingo zakho kanye nesabelomali, futhi uchwepheshe wethu we-laser uzoncoma umshini wokusika we-laser ongawukhetha.⇨I-MimoWork Laser

Umthombo we-Laser

Lapho utshala imali emshinini wokusika we-laser, udinga ukwazi ukuthi yimuphi umthombo we-laser okwazi ukusika izinto zakho futhi ufinyelele umphumela wokusika olindelekile. Kunemithombo emibili evamile ye-laser:i-fiber laser ne-CO2 laser. I-fiber laser isebenza kahle ekusikeni nasekumaka entweni yensimbi ne-alloy. I-CO2 laser ikhethekile ekusikeni nasekuqopheni izinto ezingezona ezensimbi. Ngenxa yokusetshenziswa kakhulu kwama-laser e-CO2 kusukela ezingeni lemboni kuya ezingeni lokusebenzisa ekhaya nsuku zonke, iyakwazi futhi kulula ukuyisebenzisa. Xoxa ngezinto zakho nochwepheshe bethu be-laser, bese unquma umthombo we-laser ofanele.

Ukucushwa komshini

Ngemuva kokunquma umthombo we-laser, udinga ukuxoxa ngezidingo zakho ezithile zokusika izinto ezifana nesivinini sokusika, umthamo wokukhiqiza, ukunemba kokusika, kanye nezakhiwo zezinto ezibonakalayo nochwepheshe wethu we-laser. Lokho kunquma ukuthi yikuphi ukucushwa kwe-laser nezinketho ezifanele futhi kungafinyelela umphumela omuhle wokusika. Isibonelo, uma unezidingo eziphezulu zokukhishwa kokukhiqiza kwansuku zonke, isivinini sokusika nokusebenza kahle kuzoba ukucatshangelwa kwakho kokuqala. Amakhanda e-laser amaningi, amasistimu e-autofeeding kanye nama-conveyor, kanye nesofthiwe ethile yokuzalela ngokuzenzakalelayo ingase ithuthukise ukusebenza kahle kwakho kokukhiqiza. Uma umatasatasa ngokusika ukunemba, mhlawumbe i-servo motor neshubhu le-laser yensimbi zikufanele kakhulu.

Indawo Yokusebenzela

Indawo yokusebenza iyisici esibalulekile ekukhetheni imishini. Ngokuvamile, abahlinzeki bemishini ye-laser babuza mayelana nolwazi lwakho lwempahla, ikakhulukazi usayizi wempahla, ukujiya, nosayizi wephethini. Lokho kunquma ifomethi yethebula lokusebenza. Futhi uchwepheshe we-laser uzohlaziya usayizi wephethini yakho kanye nekhonsathi yomumo ngokuxoxa nawe, ukuze athole imodi yokuphakela elungile ehambisana netafula lokusebenza. Sinosayizi othile ojwayelekile wokusebenza womshini wokusika i-laser, ongahlangabezana nezidingo zamakhasimende amaningi, kepha uma unezidingo ezikhethekile zezinto ezibonakalayo kanye nezidingo zokusika, sicela usazise, uchwepheshe wethu we-laser uchwepheshe futhi unolwazi lokuphatha ukukhathazeka kwakho.

Ubuciko

Umshini wakho

| Usayizi Wokusebenza Komshini (W * L) |

| •600mm * 400mm |

| •1000mm * 600mm |

| •1300mm * 900mm |

| •1300mm * 2500mm |

| •1600mm * 1000mm |

| •1600mm * 1200mm |

| •1600mm * 3000mm |

| •1600mm * 10000mm |

| •1800mm * 1400mm |

| •2500mm * 3000mm |

| •3200mm * 1400mm |

Uma Unezidingo Ezikhethekile Zosayizi Womshini, Khuluma nathi!

Umkhiqizi womshini

Kulungile, unolwazi lwakho lwempahla, izidingo zokusika, nezinhlobo zomshini eziyisisekelo, isinyathelo esilandelayo osidingayo ukucinga umenzi womshini wokusika we-laser othembekile. Ungasesha ku-Google, naku-YouTube, noma uthintane nabangane bakho noma ozakwethu, noma ngayiphi indlela, ukwethembeka nobuqiniso babahlinzeki bemishini kuhlala kubaluleke kakhulu. Zama ukubathumelela i-imeyili, noma uxoxe nochwepheshe babo belaser ku-WhatsApp, ukuze ufunde kabanzi mayelana nokukhiqizwa komshini, lapho imboni ilele khona, indlela yokuqeqesha nokuqondisa ngemva kokuthola umshini, nokunye okunjalo. Amanye amaklayenti ake a-oda umshini ovela ezimbonini ezincane noma amapulatifomu ezinkampani zangaphandle ngenxa yentengo ephansi, noma kunjalo, uma umshini unezinkinga ezithile, awutholi noma yiluphi usizo nokusekelwa, okuzobambezela ukukhiqiza kwakho nokuchitha isikhathi.

I-MimoWork Laser Ithi: Sihlala sibeka izidingo zeklayenti futhi sisebenzisa ulwazi kuqala. Okutholayo akuwona nje umshini we-laser omuhle futhi oqinile, kodwa futhi isethi yesevisi ephelele nokusekelwa kusukela ekufakweni, ukuqeqeshwa kuya ekusebenzeni.

① Thola Umkhiqizi Othembekile

I-Google & Usesho lwe-YouTube, noma vakashela ireferensi yendawo

② Bheka Iwebhusayithi yayo noma i-YouTube

Hlola izinhlobo zemishini nolwazi lwenkampani

③ Xhumana Nochwepheshe Be-Laser

Thumela i-imeyili noma xoxa nge-WhatsApp

⑥ Faka i-oda

Nquma isikhathi sokukhokha

⑤ Thola Ezokuthutha

ngemikhumbi noma emoyeni

④ Umhlangano We-inthanethi

Xoxa nge-soultion yomshini we-laser olungile

Mayelana Nokubonisana Nomhlangano

> Yiluphi ulwazi okufanele ulunikeze?

> Imininingwane yethu yokuxhumana

UKUSEBENZA

7. Indlela yokusebenzisa Laser Cutting Machine?

I-Laser Cutting Machine ingumshini ohlakaniphile futhi ozenzakalelayo, ngokusekelwa kwesistimu ye-CNC kanye nesofthiwe yokusika i-laser, umshini we-laser ungabhekana nehluzo eziyinkimbinkimbi futhi uhlele indlela yokusika efanele ngokuzenzakalelayo. Udinga nje ukungenisa ifayela lokusika ohlelweni lwe-laser, khetha noma usethe imingcele yokusika i-laser njengejubane namandla, bese ucindezela inkinobho yokuqala. Umsiki we-laser uzoqeda yonke inqubo yokusika. Ngenxa yomkhawulo wokusika ophelele onqenqemeni olubushelelezi nendawo ehlanzekile, awudingi ukusika noma ukupholisha izingcezu eziqediwe. Inqubo yokusika i-laser iyashesha futhi ukusebenza kulula futhi kunobungane kwabaqalayo.

▶ Isibonelo 1: Indwangu Yokusika I-Laser

Isinyathelo 1. Faka i-Roll Fabric ku-Auto-Feeder

Lungiselela Indwangu:Beka indwangu egoqwayo ohlelweni lokuphakelayo okuzenzakalelayo, gcina indwangu isicaba futhi unqenqema icocekile, bese uqala i-auto feeder, beka indwangu yokugoqa etafuleni lokuguqula.

Umshini we-Laser:Khetha umshini wokusika we-laser wendwangu onesiphakeli esizenzakalelayo kanye netafula lokudlulisa. Indawo yokusebenza yomshini idinga ukufanisa ifomethi yendwangu.

▶

Isinyathelo 2. Ngenisa Ifayela Lokusika & Setha Amapharamitha we-Laser

Ifayela Lokuklama:Ngenisa ifayela lokusika kusofthiwe yokusika i-laser.

Setha Amapharamitha:Ngokuvamile, udinga ukusetha amandla e-laser nesivinini se-laser ngokuya ngokushuba kwezinto, ukuminyana, kanye nezidingo zokusika ukunemba. Izinto ezincanyana zidinga amandla aphansi, ungahlola isivinini se-laser ukuze uthole umphumela ofanele wokusika.

▶

Isinyathelo sesi-3. Qala Indwangu Yokusika I-Laser

I-Laser Cut:Iyatholakala kumakhanda okusika ama-laser amaningi, ungakhetha amakhanda e-laser amabili ku-gantry eyodwa, noma amakhanda e-laser amabili kuma-gantry amabili azimele. Lokho kuhlukile ekukhiqizweni kokusika kwe-laser. Udinga ukuxoxa nochwepheshe bethu be-laser mayelana nephethini yakho yokusika.

▶ Isibonelo sesi-2: I-Laser Cutting Printed Acrylic

Isinyathelo 1. Beka Ishidi Le-Acrylic Kuthebula Lokusebenza

Beka Material:Beka i-acrylic ephrintiwe etafuleni lokusebenza, nge-laser cutting acrylic, sasebenzisa ithebula lokusika ummese elingavimba ukuthi impahla ingashi.

Umshini we-Laser:Siphakamisa ukusebenzisa i-acrylic laser engraver 13090 noma i-laser cutter enkulu engu-130250 ukusika i-acrylic. Ngenxa yephethini ephrintiwe, ikhamera ye-CCD iyadingeka ukuze kuqinisekiswe ukusika okunembile.

▶

Isinyathelo 2. Ngenisa Ifayela Lokusika & Setha Amapharamitha we-Laser

Ifayela Lokuklama:Ngenisa ifayela lokusika kusofthiwe yokuqaphela ikhamera.

Setha Amapharamitha:In jikelele, udinga ukusetha amandla e-laser nesivinini se-laser ngokuya ngokujiya kwezinto, ukuminyana, kanye nezidingo zokusika ukunemba. Izinto ezincanyana zidinga amandla aphansi, ungahlola isivinini se-laser ukuze uthole umphumela ofanele wokusika.

▶

Isinyathelo 3. Ikhamera ye-CCD Ibona Iphethini Ephrintiwe

Ukubonwa kwekhamera:Okokusebenza okuphrintiwe njengendwangu ye-acrylic ephrintiwe noma i-sublimation, isistimu yokuqaphela ikhamera iyadingeka ukuze ibone futhi imise iphethini, futhi iyalele ikhanda le-laser ukuthi lisike eduze nekhontowuni elungile.

Isinyathelo sesi-4. Qala Ukusika i-Laser ngokuhambisana ne-Contour yephethini

Ukusika i-Laser:Bnjengoba kufakwe endaweni yekhamera, ikhanda lokusika i-laser lithola indawo elungile bese liqala ukusika eduze kwekhontoyutha yephethini. Yonke inqubo yokusika iyazenzakalela futhi iyaguquguquka.

▶ Amathiphu Namasu Lapho Usika i-Laser

✦ Ukukhethwa Kwezinto:

Ukuze ufinyelele umphumela omuhle wokusika we-laser, udinga ukuphatha izinto kusengaphambili. Ukugcina okokusebenza kuyisicaba futhi kuhlanzekile kuyadingeka ukuze ubude be-laser cutting focal bufane ukugcina umphumela wokusika umkhulu ngokungaguquki. Kunezinhlobo eziningi ezahlukeneizinto zokwakhaokungasikwa futhi kuqoshwe i-laser, nezindlela zokwelapha zangaphambi kokwelashwa zihlukile, uma umusha kulokhu, ukukhuluma nochwepheshe bethu be-laser kuyisinqumo esingcono kakhulu.

✦Hlola kuqala:

Yenza ukuhlolwa kwe-laser usebenzisa izingcezu ezithile zamasampuli, ngokusetha amandla e-laser ahlukene, isivinini se-laser ukuze uthole amapharamitha e-laser alungile, ukuze kuphumele emphumeleni wokusika ophelele ohlangabezana nezidingo zakho.

✦Ukungenisa umoya:

Izinto zokusika i-laser zingase zikhiqize intuthu kanye negesi eyimfucumfucu, ngakho-ke kudingeka uhlelo lokungenisa umoya olwenziwa kahle. Imvamisa sihlomisa isiphephetha-moya esikhipha umoya ngokwendawo yokusebenza, usayizi womshini, nezinto zokusika.

✦ Ukuphepha Kokukhiqiza

Kwezinye izinto ezikhethekile njengezinto eziyinhlanganisela noma izinto zepulasitiki, siphakamisa ukuthi amaklayenti ahlomisei-fume extractorngomshini wokusika we-laser. Lokho kungenza indawo yokusebenza ihlanzeke futhi iphephe.

✦ Thola i-Laser Focus:

Qinisekisa ukuthi i-laser beam igxile kahle endaweni ebonakalayo. Ungasebenzisa izindlela zokuhlola ezilandelayo ukuze uthole ubude obuqondile be-laser, futhi ulungise ibanga ukusuka ekhanda le-laser ukuya endaweni ebonakalayo ngaphakathi kobubanzi obuthile obuzungeze ubude bokugxila, ukuze ufinyelele umphumela ofanele wokusika nokuqopha. Kukhona umehluko wokusetha phakathi kokusika kwe-laser nokuqoshwa kwe-laser. Ukuze uthole imininingwane mayelana nendlela yokuthola ubude bokugxila obufanele, sicela uhlole ividiyo >>

Okokufundisa kwevidiyo: Ungakuthola Kanjani Ukugxila Okulungile?

▶ Nakekela I-Chiller Yakho Yamanzi

I-chiller yamanzi idinga ukusetshenziswa endaweni enomoya futhi epholile. Futhi ithangi lamanzi lidinga ukuhlanzwa njalo futhi amanzi kufanele ashintshwe njalo ezinyangeni ezi-3. Ebusika, ukufaka i-antifreeze ku-chiller yamanzi kuyadingeka ukuze kuvinjelwe ukuqanda. Funda kabanzi mayelana nendlela yokulondoloza amanzi abandayo ebusika, sicela uhlole ikhasi:Izinyathelo zokuvikela ukuqina kwe-Laser Cutter ebusika

▶ Hlanza Ilensi yokugxilisa ingqondo nezibuko

Lapho i-laser isika futhi iqoshwa ezinye izinto, ezinye izintuthu, udoti, ne-resin zizokhiqizwa futhi zishiywe ezibukweni nakumalensi. Udoti oqoqiwe udala ukushisa ukuze kulimaze ilensi nezibuko, futhi unomthelela ekuphumeni kwamandla e-laser. Ngakho-ke ukuhlanza i-lens yokugxila nezibuko kuyadingeka. Gcoba i-swab kakotini emanzini noma etshwaleni ukuze usule i-lens, khumbula ukuthi ungayithinti indawo engaphezulu ngezandla zakho. Kukhona umhlahlandlela wevidiyo ngalokho, bheka lokhu >>

▶ Gcina Ithebula Lokusebenza Lihlanzekile

Ukugcina itafula lokusebenza lihlanzekile kubalulekile ukunikeza indawo yokusebenza ehlanzekile neyisicaba yezinto zokwakha kanye nekhanda lokusika i-laser. I-resin nezinsalela azigcini nje ngokungcolisa izinto, kodwa futhi zithinta umphumela wokusika. Ngaphambi kokuhlanza itafula lokusebenza, udinga ukuvala umshini. Bese usebenzisa isicoci se-vacuum ukususa uthuli nemfucumfucu esele etafuleni lokusebenza bese ushiya ebhokisini lokuqoqa imfucuza. Futhi hlanza itafula lokusebenza kanye nesitimela ngethawula likakotini elimanziswe ngohlanzekile. Ilinde ukuthi itafula elisebenzayo lome, futhi lixhume amandla.

▶ Hlanza Ibhokisi Lokuqoqa Uthuli

Hlanza ibhokisi lokuqoqa uthuli nsuku zonke. Enye imfucumfucu nezinsalela ezikhiqizwe ngezinto zokusika i-laser ziwela ebhokisini lokuqoqa uthuli. Udinga ukuhlanza ibhokisi izikhathi eziningana phakathi nosuku uma umthamo wokukhiqiza mkhulu.

• Qinisekisa lokho ngezikhathi ezithileukuphepha interlockszisebenza kahle. Qinisekisa ukuthiinkinobho yokumisa isimo esiphuthumayo, ukukhanya kwesignalizigijima kahle.

•Faka umshini ngaphansi kokuqondisa kukachwepheshe we-laser.Ungalokothi uvule umshini wakho wokusika we-laser uze uhlanganiswe ngokugcwele futhi zonke izembozo zisendaweni.

•Ungasebenzisi i-laser cutter kanye nomqophi eduze kwanoma yimuphi umthombo wokushisa ongaba khona.Njalo gcina indawo ezungeze isisiki ingenawo udoti, imfuhlumfuhlu, nezinto ezivuthayo.

• Ungazami ukulungisa umshini wokusika we-laser uwedwa -thola usizo lochwepheshekusuka kuchwepheshe be-laser.

•Sebenzisa izinto zokuvikela nge-laser. Ezinye izinto eziqoshwe, ezimakwe, noma ezisikwe ngelaser zingakhiqiza intuthu enobuthi negqwalayo. Uma ungaqiniseki, sicela uxhumane nochwepheshe bakho be-laser.

•UNGALINGE usebenzise uhlelo ungagadiwe. Qinisekisa ukuthi umshini we-laser usebenza ngaphansi kokuqondisa komuntu.

• AI-fire extinguisherKufanele Igxunyekwe Odongeni Eduze Kwesisiki Se-Laser.

• Ngemva kokusika ezinye izinto zokuqhuba ukushisa, wenabadinga ama-tweezers noma amagilavu awugqinsi ukuze bathathe impahla.

• Kwezinye izinto ezifana nepulasitiki, ukusikwa nge-laser kungase kukhiphe intuthu eminingi nothuli indawo osebenzela kuyo engayivumeli. Khona-ke ai-fume extractorkuyisinqumo sakho esingcono kakhulu, esingamunca futhi sihlanze udoti, siqinisekise ukuthi indawo yokusebenza ihlanzekile futhi iphephile.

•Izibuko zokuphepha ze-laseranamalensi aklanywe ngokukhethekile afakwe umbala ukuze amunce ukukhanya kwelaser futhi akuvimbele ukuthi kungadluleli kuye emehlweni omuntu ogqokile. Izibuko kufanele zihambisane nohlobo lwe-laser (kanye nobude begagasi) oyisebenzisayo. Futhi ijwayele ukuba imibala ehlukene ngokuya ngobude begagasi abamuncayo: okuluhlaza okwesibhakabhaka noma okuluhlaza kumalaser e-diode, okumpunga kumalaser e-CO2, kanye nokuluhlaza okukhanyayo kumalaser efiber.

FAQ

• Ungakanani umshini wokusika i-laser?

Abasiki be-laser be-CO2 abayisisekelo bahluka ngentengo ukusuka ngaphansi kuka-$2,000 ukuya ngaphezulu kuka-$200,000. Umehluko wamanani mkhulu impela uma kukhulunywa ngokucushwa okuhlukile kwe-CO2 laser cutters. Ukuze uqonde izindleko zomshini we-laser, udinga ukucabangela okungaphezu kwethegi yentengo yokuqala. Kufanele futhi ucabangele zonke izindleko zokuba ngumnikazi womshini we-laser kukho konke ukuphila kwawo, ukuze uhlole kangcono ukuthi kuwufanele yini ukutshala imali ocezwini lwesisetshenziswa se-laser. Imininingwane mayelana nezintengo zomshini wokusika we-laser ukuze uhlole ikhasi:Ubiza Malini Umshini We-Laser?

• Usebenza kanjani umshini wokusika i-laser?

I-laser beam iqala emthonjeni we-laser, futhi iqondiswe futhi igxiliswe izibuko futhi igxilise ilensi ekhanda le-laser, bese idutshulwa phezu kokusebenza. Uhlelo lwe-CNC lulawula ukukhiqizwa kwe-laser beam, amandla kanye nokushaya kwe-laser, kanye nendlela yokusika yekhanda le-laser. Kuhlanganiswe ne-air blower, i-exhaust fan, idivayisi enyakazayo kanye netafula lokusebenza, inqubo eyisisekelo yokusika i-laser ingaqedwa kahle.

• Iyiphi igesi esetshenziswa emshinini wokusika we-laser?

Kunezingxenye ezimbili ezidinga igesi: i-resonator nekhanda lokusika i-laser. Ku-resonator, igesi ehlanganisa ukuhlanzeka okuphezulu (ibanga lesi-5 noma okungcono) i-CO2, i-nitrogen, ne-helium kuyadingeka ukuze kukhiqizwe i-laser beam. Kodwa ngokuvamile, awudingi ukushintsha la magesi. Ngekhanda lokusika, igesi ye-nitrogen noma i-oksijini yokusiza iyadingeka ukusiza ukuvikela izinto ezizocutshungulwa futhi kuthuthukiswe i-laser beam ukuze kufinyelele umphumela ofanele wokusika.

• Uyini Umehluko: I-Laser Cutter VS Laser Cutter?

Mayelana ne-MimoWork Laser

I-Mimowork ikhiqiza i-laser egxile emiphumeleni, ezinze e-Shanghai nase-Dongguan China, iletha iminyaka engu-20 yobuchwepheshe bokusebenza obujulile ukukhiqiza izinhlelo ze-laser futhi inikeze izixazululo eziphelele zokucubungula nokukhiqiza kuma-SME (amabhizinisi amancane naphakathi nendawo) ezimbonini eziningi eziningi.

Okuhlangenwe nakho kwethu okucebile kwezixazululo ze-laser zokucubungula izinto zensimbi nezingezona ezensimbi kugxilile emhlabeni jikeleleisikhangiso, ezezimoto & zezindiza, insimbi, udayi sublimation izicelo, indwangu kanye nezindwanguizimboni.

Kunokuba inikeze isixazululo esingaqinisekile esidinga ukuthengwa kubakhiqizi abangafanelekile, iMimoWork ilawula yonke ingxenye yochungechunge lokukhiqiza ukuze iqinisekise ukuthi imikhiqizo yethu isebenza kahle kakhulu.

Ngokushesha Funda Kabanzi:

Gxumela Emhlabeni Womlingo Womshini Wokusika weLaser,

Xoxa nochwepheshe bethu be-Laser!

Isikhathi sokuthumela: May-27-2024