ISANDULELA UKUSIKA LASER

Kukho usetyenziso lwelaser olwahlukeneyo ukusuka kwipeni yelaser yokufundisa ukuya kwizixhobo zelaser kugwayimbo olude. I-Laser Cutting, njengolwahlulo lwezicelo, iphuhlisiwe kwaye ivelele kwiindawo zokusika kunye nokukrola. Ngeempawu ze-laser ezigqwesileyo, ukusebenza okugqwesileyo kokusika, kunye nokusebenza ngokuzenzekelayo, oomatshini bokusika i-laser bathatha indawo yezinye izixhobo zokusika zemveli. I-CO2 Laser yeyona ndlela ixhaphakileyo yokusetyenzwa. Ubude be-10.6μm buhambelana phantse nazo zonke izinto ezingezizo zetsimbi kunye nentsimbi edibeneyo. Ukusuka kwilaphu lemihla ngemihla kunye nesikhumba, ukuya kwiplastiki esetyenziswa kwimizi-mveliso, iglasi, kunye ne-insulation, kunye nezinto zobugcisa ezifana nomthi kunye ne-acrylic, umatshini wokusika we-laser uyakwazi ukuphatha oku kunye nokuqonda imiphumo emihle yokusika. Ngoko ke, nokuba usebenza ngezinto zokusika kunye nokukrola ukusetyenziswa kwezorhwebo kunye nezoshishino, okanye ufuna ukutyalomali kumatshini omtsha wokusika wokuzilibazisa kunye nomsebenzi wesipho, ukuba nolwazi oluncinci lokusika i-laser kunye nomatshini wokusika i-laser kuya kuba luncedo olukhulu kuwe ukuba wenze isicwangciso.

ITHEKNOLOJI

1. Yintoni iLaser Cutting Machine?

I-Laser Cutting Machine ngumatshini onamandla wokusika kunye nokukrola olawulwa yinkqubo ye-CNC. Umqa welaser oguquguqukayo nonamandla usuka kwityhubhu yelaser apho kwenzeka khona ukusabela kombane womlingo. Iityhubhu ze-laser ze-CO2 zokusika iLaser zihlulwe zibe ziindidi ezimbini: iityhubhu zeglasi kunye neetyhubhu zentsimbi. Umqa welaser okhutshiweyo uya kudluliselwa kwizinto oza kusikwa ngezipili ezithathu kunye nelensi enye. Akukho uxinzelelo lomatshini, kwaye akukho qhagamshelwano phakathi kwentloko ye-laser kunye nezinto eziphathekayo. Umzuzu xa umqa welaser othwele ubushushu obuninzi udlula kwizinto eziphathekayo, uyakhutshwa ngumphunga okanye ufakwe ngaphantsi. Akukho nto iseleyo ngaphandle kwe kerf entle ebhityileyo kwizinto eziphathekayo. Le yinkqubo esisiseko kunye nomgaqo wokusika i-CO2 laser. I-laser beam enamandla ihambelana nenkqubo ye-CNC kunye nesakhiwo sothutho esiyinkimbinkimbi, kwaye umatshini wokusika we-laser osisiseko wakhiwe kakuhle ukuze usebenze. Ukuqinisekisa ukusebenza okuzinzile, umgangatho ogqibeleleyo wokusika, kunye nokuveliswa okukhuselekileyo, umatshini wokusika we-laser uxhotyiswe ngenkqubo yokuncedisa umoya, i-fan exhaust, i-exclosure device kunye nabanye.

2. Isebenza njani iLaser Cutter?

Siyazi ukuba i-laser isebenzisa ubushushu obukhulu ukusika izinto. Ngoko ke, ngubani othumela umyalelo wokwalathisa indlela eshukumayo nendlela yokusika? Ewe, yinkqubo ye-laser cnc ekrelekrele kubandakanya isoftware yokusika i-laser, ibhodi yokulawula, inkqubo yesekethe. Inkqubo yolawulo oluzenzekelayo yenza ukuba ukusebenza kube lula kwaye kube lula, nokuba ungumntu oqalayo okanye oyingcali. Sidinga nje ukungenisa ifayile yokusika kwaye sibeke iiparamitha ezifanelekileyo ze-laser njengesantya kunye namandla, kwaye umatshini wokusika i-laser uya kuqalisa inkqubo yokusika elandelayo ngokwemiyalelo yethu. Yonke inkqubo yokusika i-laser kunye nokukrola iyahambelana kwaye ichanekileyo ngokuphindaphindiweyo. Akumangalisi ukuba i-laser yintshatsheli yesantya kunye nomgangatho.

3. Isakhiwo seLaser Cutter

Ngokubanzi, umatshini wokusika we-laser uqukethe iinxalenye ezine eziphambili: indawo yokukhupha i-laser, inkqubo yokulawula, inkqubo yokunyakaza, kunye nenkqubo yokhuseleko. Yonke icandelo lidlala indima ebalulekileyo ekusikeni ngokuchanekileyo nangokukhawuleza kunye nokukrola. Ukwazi malunga nezakhiwo kunye namacandelo oomatshini bokusika i-laser, akuncedi kuphela ukuba wenze isigqibo esifanelekileyo xa ukhetha kwaye uthenge umatshini, kodwa ubonelela ngokuguquguquka ngakumbi ekusebenzeni kunye nokwandiswa kwemveliso yexesha elizayo.

Nantsi intshayelelo kwiindawo eziphambili zomatshini wokusika i-laser:

Umthombo weLaser:

I-CO2 Laser:Isebenzisa umxube werhasi owenziwe ikakhulu yikharbon diokside, iyenza ilungele ukusika izinto ezingezizo ezentsimbi njengemithi, i-acrylic, ilaphu, kunye neentlobo ezithile zamatye. Isebenza kumgama omalunga ne-10.6 ye-micrometers.

IFayibha Laser:Isebenzisa itekhnoloji yelaser eqinileyo enemicu ebonayo edityaniswe nezinto ezinqabileyo zomhlaba ezifana neytterbium. Isebenza kakuhle kakhulu ekusikeni iintsimbi ezifana nentsimbi, i-aluminium, kunye nobhedu, esebenza kumgama ojikeleze i-1.06 micrometers.

Nd:YAG Laser:Isebenzisa ikristale ye-neodymium-doped yttrium aluminiyam garnet. Iguquguquka kwaye inokusika zombini iintsimbi kunye nezinye ezingezizo iintsimbi, nangona ingaqhelekanga kune-CO2 kunye ne-fiber lasers yokusika izicelo.

Umbhobho weLaser:

Izindlu i-laser medium (i-CO2 igesi, kwimeko ye-CO2 lasers) kwaye ivelisa i-laser beam ngokusebenzisa ukukhutshwa kombane. Ubude kunye namandla ityhubhu ye-laser ichaza amandla okusika kunye nobukhulu bezinto ezinokunqunyulwa. Kukho iindidi ezimbini zetyhubhu yelaser: ityhubhu yeglasi yeglasi kunye netyhubhu yentsimbi yelaser. Iingenelo zeetyhubhu zeglasi ze-laser zilungele uhlahlo lwabiwo-mali kwaye ziyakwazi ukuphatha ukusika izinto ezilula ngaphakathi koluhlu oluthile oluchanekileyo. Izibonelelo zeetyhubhu ze-laser zetsimbi zixesha elide lenkonzo kunye nokukwazi ukuvelisa ukuchaneka okuphezulu kwe-laser.

Indlela yokubona:

Izipili:Ibekwe ngokucwangcisekileyo ukuqondisa i-laser beam ukusuka kwi-laser tube ukuya kwintloko yokusika. Kufuneka zilungelelaniswe ngokuchanekileyo ukuqinisekisa ukuhanjiswa kwe-beam ngokuchanekileyo.

Iilensi:Gxininisa i-laser beam ukuya kwindawo efanelekileyo, ukunyusa ukuchaneka kokusika. Ubude be-lens buchaphazela ugxininiso lwe-beam kunye nobunzulu bokusika.

Intloko yokusika iLaser:

ILens eQinisekisayo:Iguqula umqa welaser ube yindawo encinci yokusika ngokuchanekileyo.

Umbhobho:Izikhokelo zinceda iigesi (ezifana neoksijini okanye initrogen) kwindawo yokusika ukunyusa ukusebenza kakuhle kokusika, ukuphucula umgangatho wokusika, kunye nokuthintela ukwakhiwa kobutyobo.

Isivamvo soBude:Ugcina umgama ohambelanayo phakathi kwentloko yokusika kunye nezinto eziphathekayo, ukuqinisekisa umgangatho wokusikwa okufanayo.

Umlawuli we-CNC:

I-Computer Numerical Control (CNC) Inkqubo: Ilawula imisebenzi yomatshini, kubandakanywa ukunyakaza, amandla e-laser, kunye nesantya sokusika. Itolika ifayile yoyilo (ngokuqhelekileyo kwi-DXF okanye iifomati ezifanayo) kwaye iguqulela kwiintshukumo ezichanekileyo kunye nezenzo ze-laser.

Itheyibhile yokuSebenza:

Itheyibhile yokuShutha:Itafile ye-shuttle, ekwabizwa ngokuba yi-pallet changer, yakhiwe ngoyilo lokudlula ukuze ihanjiswe ngeendlela ezimbini. Ukuququzelela ukulayishwa kunye nokukhulula izinto ezinokuthi zinciphise okanye ziphelise ixesha lokuphumla kwaye zihlangabezane nokusika izixhobo zakho ezithile, senze iisayizi ezahlukeneyo ukuze zihambelane nobukhulu obunye boomatshini bokusika iMimoWork laser.

Ibhedi yeLaser yenqatha lobusi:Inika indawo ethe tyaba kwaye ezinzileyo enendawo encinci yokunxibelelana, ukunciphisa ukubonakaliswa ngasemva kunye nokuvumela ukusika okucocekileyo. Ibhedi yobusi ye-laser ivumela ukungena komoya ngokulula kobushushu, uthuli, kunye nomsi ngexesha lenkqubo yokusika i-laser.

Itheyibhile yeKnife Strip:Ngokuyintloko yeyokusika izixhobo ezityebileyo apho ungathanda ukunqanda ukubuyisela umva ngelaser. Imivalo ethe nkqo ikwavumela eyona nto ihamba kakuhle yokukhupha ngelixa usika. I-Lamellas inokubekwa ngabanye, ngenxa yoko, itafile ye-laser inokulungiswa ngokwesicelo somntu ngamnye.

Itheyibhile yoMhambisi:Itafile yokuhambisa yenziwe ngayoweb steel stainlesseyilungeleyoizinto ezibhityileyo kunye bhetyebhetye ezifanaifilimu,ilaphukwayengethwathwa.Ngenkqubo yokuhambisa, ukusika kwe-laser okungapheliyo kuya kuba nokwenzeka. Ukusebenza kakuhle kweMimoWork laser systems kungandiswa ngakumbi.

Itheyibhile ye-Acrylic Cutting Grid:Kubandakanya itafile yokusika i-laser kunye negridi, igridi ekhethekileyo ye-laser engraver ikhusela ukubuyisela umva. Ngoko ke kulungele ukusika i-acrylics, i-laminates, okanye iifilimu zeplastiki ezineengxenye ezincinci kune-100 mm, njengoko ezi zihlala kwindawo ethe tyaba emva kokusikwa.

I-Pin Working Table:Iqulethe izikhonkwane ezininzi ezihlengahlengiswayo ezinokucwangciswa kwiindlela ezahlukeneyo zokuxhasa izinto ezisikwayo. Olu luyilo lunciphisa unxibelelwano phakathi kwezinto kunye nomphezulu womsebenzi, lubonelela ngeenzuzo ezininzi zokusika i-laser kunye nezicelo zokukrola.

Inkqubo yentshukumo:

I-Stepper Motors okanye i-Servo Motors:Qhuba i-X, Y, kwaye ngamanye amaxesha i-Z-axis iintshukumo zentloko yokusika. Iinjini zeServo zichaneke ngakumbi kwaye zikhawuleza kuneemotor ezinyathelayo.

IziKhokelo eziLayini kunye neeRail:Qinisekisa ukunyakaza okugudileyo kunye nokuchanekileyo kwentloko yokusika. Zibalulekile ukugcina ukuchaneka kokusika kunye nokuhambelana ngexesha elide.

Inkqubo yokupholisa:

IChiller yamanzi: Igcina ityhubhu ye-laser kunye namanye amacandelo kwiqondo lobushushu obufanelekileyo ukuthintela ukutshisa nokugcina ukusebenza okungaguqukiyo.

Uncedo lomoya:Uvuthuza umjelo womoya ngombhobho ukususa inkunkuma, ukunciphisa iindawo ezichatshazelwe bubushushu, kunye nokuphucula umgangatho wokusika.

Inkqubo yokukhupha:

Susa umsi, umsi, kunye nombandela owenziwe ngexesha lokusika, uqinisekisa indawo yokusebenza ecocekileyo nekhuselekileyo. Ukungena komoya okufanelekileyo kubalulekile ekugcineni umgangatho womoya kunye nokukhusela umsebenzi kunye nomatshini.

Iphaneli yokulawula:

Ibonelela nge-interface yabaqhubi kwiisetingi zegalelo, ukubeka iliso kwimeko yomatshini, kunye nokulawula inkqubo yokusika. Isenokubandakanya umboniso wesikrini esichukumisayo, iqhosha lokumisa likaxakeka, kunye nokhetho lolawulo lwezandla ukulungiselela uhlengahlengiso oluhle.

Iimpawu zoKhuseleko:

IsiXhobo esivalekileyo:Khusela abaqhubi kwi-laser exposure kunye nobutyobo obunokubakho. Iindawo ezivaliweyo zihlala zitshixiwe ukuvala i-laser ukuba ivuliwe ngexesha lokusebenza.

IQhosha lokumisa likaNgxamiseko:Ivumela ukuvalwa kwangoko komatshini kwimeko kaxakeka, iqinisekisa ukhuseleko lomsebenzisi.

Iinzwa zoKhuseleko lweLaser:Khangela naziphi na izinto ezingaqhelekanga okanye iimeko ezingakhuselekanga, ezibangela ukucima ngokuzenzekelayo okanye izilumkiso.

Isoftware:

Isoftware yokusika iLaser: MimoCUT, isoftware yokusika i-laser, yenzelwe ukwenza lula umsebenzi wakho wokusika. Ukulayisha ngokulula iifayile zakho ze-laser cut vector. I-MimoCUT iya kuguqulela imigca echaziweyo, amanqaku, i-curves, kunye neemilo kulwimi lweprogram olunokuthi luqatshelwe yi-software ye-laser cutter, kwaye ikhokele umatshini we-laser ukuphumeza.

Auto-Nest Software:MimoNEST, i-software ye-laser yokusika i-nesting software inceda abaqulunqi ukuba banciphise ixabiso lezinto kunye nokuphucula izinga lokusetyenziswa kwezinto ngokusebenzisa i-algorithms ephezulu ehlalutya ukuhluka kwamacandelo. Ngamagama alula, inokubeka iifayile zokusika i-laser kwizinto eziphathekayo ngokugqibeleleyo. Isoftware yethu yokusika i-laser yokusika ingasetyenziselwa ukusika uluhlu olubanzi lwezixhobo njengoyilo olufanelekileyo.

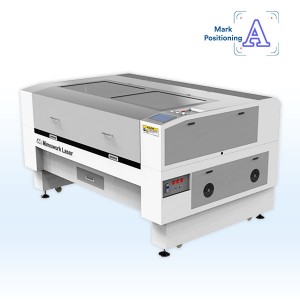

Isoftware yoQingqo lwekhamera:MimoWork iphuhlisa Ikhamera yeCCD yeLaser Positioning System enokuthi ibone kwaye ifumane iindawo zokukunceda ukuba wonge ixesha kunye nokunyusa ukuchaneka kokusika kwe-laser ngaxeshanye. Ikhamera yeCCD ixhotyiswe ecaleni kwentloko ye-laser ukukhangela i-workpiece usebenzisa amanqaku okubhalisa ekuqaleni kwenkqubo yokusika. Ngale ndlela, amanqaku ashicilelweyo, alukiweyo kunye ahonjisiweyo kunye nezinye iicontours ezinophawu oluphezulu zinokuskenwa ukuze ikhamera ye-laser cutter ikwazi ukuba iphi eyona ndawo kunye nobukhulu beziqwenga zokusebenza, ukufikelela kwipatheni echanekileyo yoyilo lokusika i-laser.

Isoftware yoqikelelo:Nge Isoftware yeMimo Projection, inkcazo kunye nesikhundla sezinto eziza kunqunyulwa ziya kuboniswa kwitafile yokusebenza, enceda ukulinganisa indawo echanekileyo yomgangatho ophezulu wokusika i-laser. Ngokuqhelekileyo iIzihlangu okanye izihlanguyokusikwa kwelaser yamkela isixhobo sokuqikelela. Njenge Isikhumba sokwenyani izihlangu, pu ngesikhumba izihlangu, ukunitha phezulu, iiteki.

Isoftware yePrototype:Ngokusebenzisa ikhamera yeHD okanye iskena sedijithali, MimoPROTOTYPE iqonda ngokuzenzekelayo imida kunye needati zokuthunga zeqhekeza ngalinye lemathiriyeli kwaye ivelise iifayile zoyilo onokuthi ungenise kwisoftware yakho yeCAD ngokuthe ngqo. Xa kuthelekiswa nenqaku lokulinganisa lemanyuwali ngokwesiko, ukusebenza kakuhle kwesoftware yomfuziselo kuphindwe kaninzi. Kufuneka ubeke kuphela iisampuli zokusika kwitafile yokusebenza.

Iigesi ezincedisayo:

Ioksijini:Ukwandisa isantya sokusika kunye nomgangatho wesinyithi ngokuququzelela ukuphendulwa kwe-exothermic, eyongeza ubushushu kwinkqubo yokusika.

I-nitrogen:Isetyenziselwa ukusika i-non-metals kunye nezinye isinyithi ukuphumeza ukusika okucocekileyo ngaphandle kwe-oxidation.

Umoya oxinanisiweyo:Isetyenziselwa ukusika iintsimbi ezingezizo ukuvuthela imathiriyeli etyhidiweyo kunye nokuthintela ukutsha.

La macandelo asebenza ngokuhambelanayo ukuze aqinisekise ngokuchanekileyo, ngokufanelekileyo, kunye nokusebenza ngokukhuselekileyo kwe-laser yokusika kwiintlobo ngeentlobo zezixhobo, ukwenza oomatshini bokusika i-laser izixhobo eziguquguqukayo kwimveliso yanamhlanje kunye nokwenziwa.

Imisebenzi emininzi kunye nokuguquguquka kwekhamera ye-laser cutter ngokukhawuleza ukusika ileyibhile elukiweyo, isitikha, kunye nefilimu encamathelayo ukuya kwinqanaba eliphezulu kunye nokusebenza okuphezulu kunye nokuchaneka okuphezulu. Iipatheni zokuprinta kunye ne-embroidery kwi-patch kunye neleyibhile ephothiweyo kufuneka inqunywe ngokuchanekileyo ...

Ukuhlangabezana neemfuno zamashishini amancinci, kunye noyilo lwesiko, iMimoWork iyile i-compact laser cutter enobungakanani bedesktop ye-600mm * 400mm. Ikhamera ye-laser cutter ifanelekile ukusika i-patch, i-embroidery, isitika, ileyibhile, kunye ne-applique esetyenziswa kwiimpahla kunye nezixhobo ...

I-contour laser cutter 90, ekwabizwa ngokuba yiCCD laser cutter iza nobungakanani bomatshini obuyi-900mm * 600mm kunye noyilo lwelaser oluvaleleke ngokupheleleyo ukuqinisekisa ukhuseleko olugqibeleleyo, ngakumbi kwabaqalayo. NgeKhamera yeCCD efakwe ecaleni kwentloko yelaser, nayiphi na ipateni kunye nokumila...

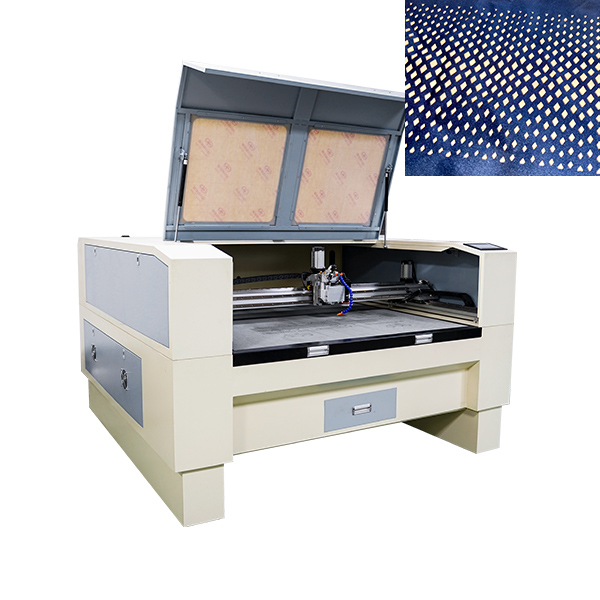

Ngokukodwa iNjineli yeMiqondiso kunye noShishino lweFanitshala, Sebenzisa Amandla oBuchule beKhamera yeCCD ekwiNgxaki yokuSika ngokugqibeleleyo iPatheni eprintiweyo yeAkriliki. NgoThutho lweSikruru seBhola kunye noKhetho lweMoto yeServo eChaneke ngokuPhezulu, Zintywilisele kuCwangciso olungaMataniswayo kunye...

Fumana i-Cutting-Edge Fusion yoBugcisa kunye neTekhnoloji kunye neMimowork's Printed Wood Laser Cutter. Ukuvula iLizwe lezinto ezinokwenzeka njengoko usika ngokungenamthungo kwaye ukrola amaplanga kunye nendalo yokhuni eprintiweyo. Yenzelwe iMiqondiso kunye noShishino lweFanitshala, iLaser Cutter yethu isebenzisa iCCD ePhezulu...

Iquka ikhamera ye-HD ye-state-of-art ebekwe phezulu, ibona ngokukhawuleza i-contours kwaye idlulisela idatha yepateni ngokuthe ngqo kumatshini wokusika ilaphu. Yithi ndlela-ntle kwiindlela ezinzima zokusika, njengoko le teknoloji inikezela ngesona sisombululo silula kunye nesona sichanekileyo seleyisi kunye...

Ukwazisa i-Laser Cut Sportswear Machine (160L) - isisombululo esiphezulu sokusika ukusika kwedayi. Ngekhamera yayo ye-HD entsha, lo matshini unokubona ngokuchanekileyo kwaye udlulise idatha yepateni ngokuthe ngqo kumatshini wokusika ipateni yelaphu. Iphakheji yethu yesoftware ibonelela ngeendlela ezahlukeneyo zokukhetha..

Ukwazisa umdlalo wokutshintsha i-Sublimation Polyester Laser Cutter (180L) - isisombululo esona sisombululo sokusika iindwangu ze-sublimation ngokuchaneka okungenakulinganiswa. Ngobukhulu betafile esebenzayo ye-1800mm * 1300mm, lo msiki wenzelwe ngokukodwa ukusetyenzwa kwepolyester eprintiweyo...

Ngena kwilizwe elikhuselekileyo, elicocekileyo, nelichane ngakumbi lokusikwa ilaphu le-sublimation ngoMatshini weZinxibo zeLaser Cut (Uvalwe Ngokupheleleyo). Ulwakhiwo lwayo oluvaliweyo lubonelela ngeenzuzo ezintathu: ukhuseleko oluphuculweyo lwabaqhubi, ulawulo oluphezulu lothuli, kunye...

Ukuhlangabezana neemfuno zokusikwa kwelaphu lefomathi enkulu kunye ebanzi, iMimoWork iyile i-ultra-wide-wide-wide sublimation laser cutter kunye neKhamera yeCCD ukunceda ukusika amalaphu ashicilelweyo njengeebhena, iiflegi ze-teardrop, imiqondiso, umboniso, umboniso, njl njl. 3200mm * 1400mm yendawo yokusebenza...

IContour Laser Cutter 160 ixhotyiswe ngekhamera yeCCD ekulungeleyo ukusetyenzwa ngoonobumba abachaneke kakhulu, amanani, iilebhile, izincedisi zempahla, iimpahla zasekhaya. Umatshini wokusika wekhamera wekhamera uchithela kwisoftware yekhamera ukuze uqonde iindawo zeempawu kwaye wenze ipateni echanekileyo yokusika ...

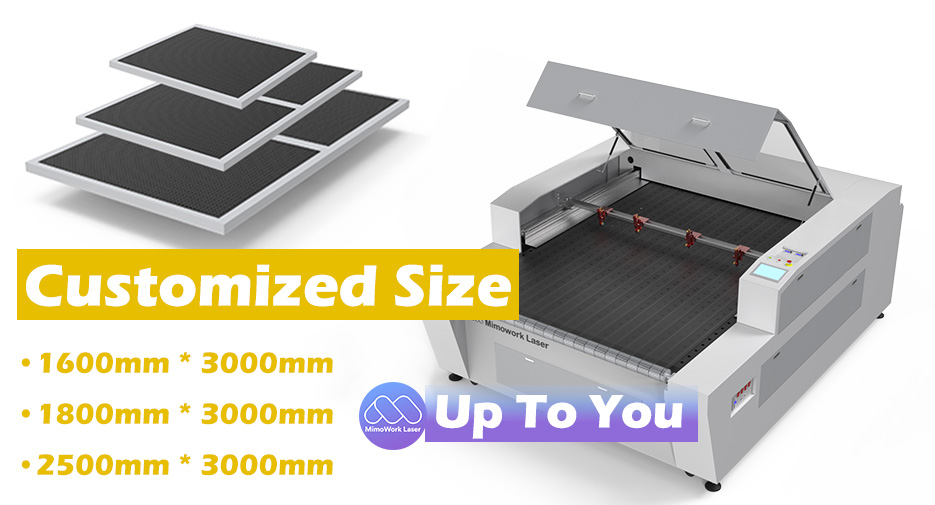

▷ Umatshini wokusika weLaser weFlatbed (Wenziwe ngokwezifiso)

Ubungakanani bomatshini obubambeneyo bugcina kakhulu indawo kwaye bunokwamkela izinto eziya ngaphaya kobubanzi obusikiweyo kunye noyilo lweendlela ezimbini zokungena. IMimowork's Flatbed Laser Engraver 100 yeyokukrola kunye nokusika izinto ezomeleleyo kunye nezixhobo ezibhetyebhetye, njengomthi, i-acrylic, iphepha, ilaphu...

Umkroli weWood Laser onokuthi ulungelelaniswe ngokupheleleyo kwiimfuno zakho kunye nohlahlo lwabiwo-mali. I-MimoWork's Flatbed Laser Cutter 130 ubukhulu becala kukukrola kunye nokusika iinkuni (iplywood, MDF), ingasetyenziswa kwi-acrylic kunye nezinye izinto. Umkrolo we-laser oguquguqukayo unceda ukufezekisa umthi owenziwe ngumntu ...

Umatshini wokukrola we-Acrylic Laser onokuthi ulungelelaniswe ngokupheleleyo kwiimfuno zakho kunye nohlahlo lwabiwo-mali. I-Mimowork's Flatbed Laser Cutter 130 yeyokukrola kunye nokusika i-acrylic (i-plexiglass/PMMA), ingasetyenziswa nakwimithi kunye nezinye izinto. Umkrolo welaser oguquguqukayo unceda...

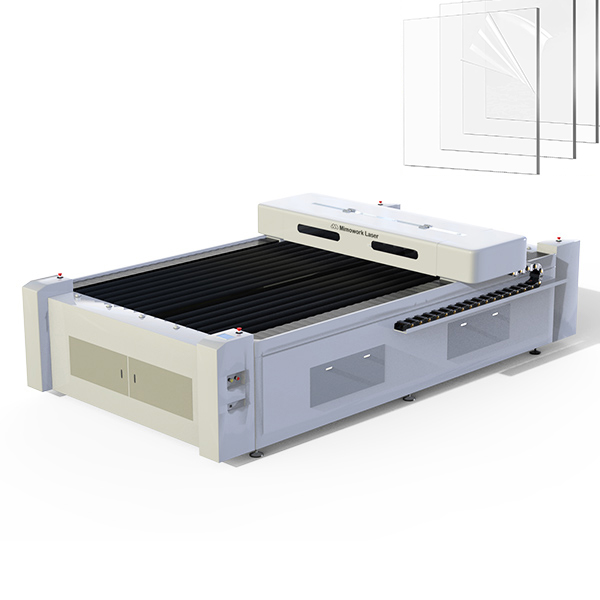

Ilungele ukusika ubukhulu obukhulu kunye namashiti amaplanga ashinyeneyo ukuhlangabezana neentengiso ezahlukeneyo kunye nokusetyenziswa kwemizi-mveliso. Itafile ye-laser ye-1300mm * 2500mm yenzelwe ukufikelela kwiindlela ezine. Ebonakala ngesantya esiphezulu, umatshini wethu wokusika i-CO2 wokhuni we-laser unokufikelela kwisantya sokusika se-36,000mm nge...

Ilungele ukusika i-laser ubungakanani obukhulu kunye namashiti ashinyeneyo e-acrylic ukuhlangabezana neentengiso ezahlukeneyo kunye nokusetyenziswa kwemizi-mveliso. Itafile ye-laser ye-1300mm * 2500mm yenzelwe ukufikelela kwiindlela ezine. I-Laser yokusika i-acrylic sheets isetyenziswa ngokubanzi kumashishini okukhanyisa kunye nezorhwebo, intsimi yokwakha ...

I-compact kunye ne-laser encinci ithatha indawo encinci kwaye kulula ukuyisebenzisa. Ukusika i-laser eguquguqukayo kunye nokukrola kuyahambelana nezi mfuno zentengiso zilungelelanisiweyo, ezibalaseleyo kwintsimi yobugcisa bephepha. Ukusika amaphepha okuntsonkothileyo kumakhadi ezimemo, amakhadi okubulisa, iincwadana, i-scrapbooking, kunye namakhadi oshishino...

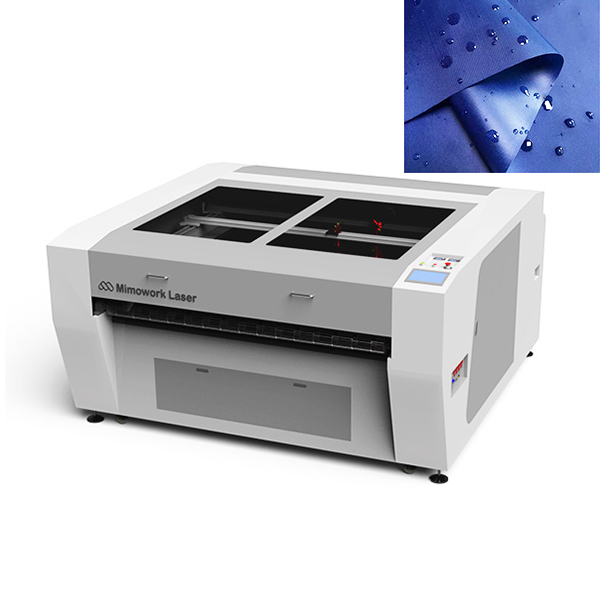

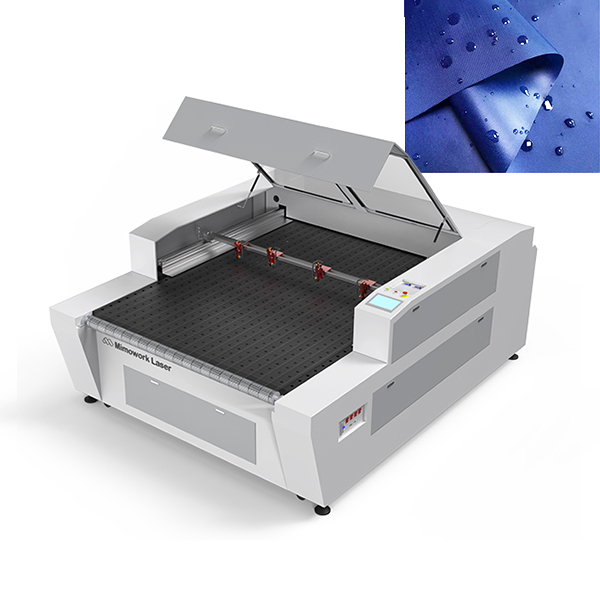

Ukufaka iimpahla eziqhelekileyo kunye nobukhulu bempahla, umatshini wokusika ilaphu welaphu unetafile yokusebenza eyi-1600mm * 1000mm. Ilaphu elithambileyo lilungele ukusika i-laser. Ngaphandle kokuba, ufele, ifilimu, ivane, idenim kunye nezinye iziqwenga zonke zinokusikwa ngelaser ngenxa yetafile esebenzayo...

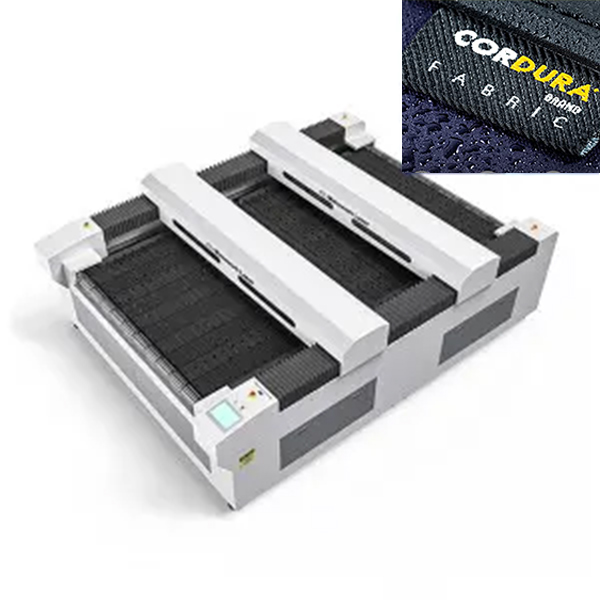

Ngokusekwe kumandla aphezulu kunye nokuxinana kweCordura, ukusika i-laser yeyona ndlela isebenzayo ngakumbi imveliso yePPE kunye nezixhobo zomkhosi. Umatshini wokusika ilaphu lemizi-mveliso we-laser uboniswe ngendawo enkulu yokusebenza ukuhlangabezana nefomathi enkulu yeCordura yokusika-njengembumbulu...

Ukuhlangabezana neentlobo ezininzi zeemfuno zokusika kwilaphu ngobukhulu obuhlukeneyo, iMimoWork yandisa umatshini wokusika we-laser ukuya kwi-1800mm * 1000mm. Idityaniswe netafile yokuhambisa, ilaphu eliqengqelekayo kunye nesikhumba sinokuvunyelwa ukuba sihambise kunye nokusikwa kwe-laser kwifashoni kunye neempahla ngaphandle kokuphazamiseka. Ukongeza, iintloko ze-laser ezininzi ...

Umatshini wokusika weLaser yeFomathi enkulu yenzelwe amalaphu amade kakhulu kunye namalaphu. Ngetafile esebenzayo yeemitha ezili-10 ubude kunye ne-1.5 yeemitha ezibanzi, ifomathi enkulu yokusika i-laser ilungele uninzi lwamalaphu amalaphu kunye nemiqulu efana nentente, iparashute, i-kitesurfing, ikhaphethi yokubhabha, i-pelmet yentengiso kunye neempawu, ilaphu lokuhamba ngesikhephe kunye njl.

Umatshini wokusika we-CO2 we-laser uxhotyiswe ngenkqubo yeprojekti enomsebenzi ochanekileyo wokumisa. Umboniso womsebenzi oza kunqunyulwa okanye ukrolwe unceda ukuba ubeke izinto kwindawo efanelekileyo, okwenza ukuba ukusika kwe-laser kunye ne-laser engraving ihambe kakuhle kunye nokuchaneka okuphezulu ...

Umatshini weLaser weGalvo (Sika kwaye ukrole & ugqobhoze)

IMimoWork Galvo Laser Marker ngumatshini oneenjongo ezininzi. Ukukrolwa kweLaser kwiphepha, iphepha lokusika i-laser yesiko kunye ne-perforating yephepha konke kunokugqitywa ngomatshini we-galvo laser. Umqa we-laser weGalvo ngokuchaneka okuphezulu, ukuguquguquka, kunye nesantya sombane kudala ulungelelwaniso ...

I-Flying laser beam ukusuka kwi-lens eguqukayo ye-angle yokuthambekela inokuqonda ukusetyenzwa ngokukhawuleza ngaphakathi kwesikali esichaziweyo. Unokuhlengahlengisa ubude bentloko yelaser ukuze ilingane nobungakanani bezinto ezicwangcisiweyo. I-RF yentsimbi ye-laser ityhubhu ibonelela ngokuchaneka okuphezulu kokumakishwa ngebala lelaser ecolekileyo ukuya kwi-0.15mm, elungele ipateni entsonkothileyo yomkrolo welaser kwisikhumba...

Umatshini we-laser we-Fly-Galvo uxhotyiswe kuphela nge-laser ye-CO2 ityhubhu kodwa unokubonelela zombini i-laser ye-laser perforating kunye ne-laser yokusika izambatho kunye neendwangu zoshishino. Ngetafile esebenzayo ye-1600mm * 1000mm, umatshini welaphu welaphu enemingxuma unokuthwala amalaphu amaninzi efomathi ezahlukeneyo, uqonda imingxunya yokusika yelaser engaguqukiyo...

I-GALVO Laser Engraver 80 enoyilo oluvaleleke ngokupheleleyo ngokuqinisekileyo lukhetho lwakho olugqibeleleyo lokukrolwa kwelaser yeshishini kunye nokumakishwa. Enkosi kumbono wayo omkhulu we-GALVO 800mm * 800mm, ilungele ukukrolwa kwelaser, ukumakisha, ukusika, kunye nokugqobhoza kwesikhumba, ikhadi lephepha, ivinyl yokuhambisa ubushushu, okanye naziphi na ezinye iziqwenga ezinkulu...

Umkroli wefomathi enkulu yelaser yiR&D yobukhulu obukhulu bezixhobo zokukrola ngelaser kunye nokumakishwa kwelaser. Ngenkqubo yokuhambisa, umkroli we-galvo laser unokukrola kwaye uphawule kumalaphu aqengqelekayo (amalaphu). Ungayijonga njengomatshini wokukrola welaphu welaphu, umatshini wokukrola wekhaphethi we-laser, umkroli wedenim laser...

Uhlahlo lwabiwo-mali

Nokuba ngabaphi na oomatshini obakhethayo ukubathenga, iindleko ezibandakanya ixabiso lomatshini, iindleko zokuthumela, ukufakwa, kunye neendleko zokulungisa emva kokugcina zihlala ziqwalaselwe kuqala. Kwinqanaba lokuthenga kwangaphambili, unokumisela ezona mfuno zibalulekileyo zokusika kwimveliso yakho ngaphakathi komda othile wohlahlo lwabiwo-mali. Fumana ulungelelwaniso lwe-laser kunye nokukhethwa komatshini we-laser ohambelana nemisebenzi kunye nohlahlo lwabiwo-mali. Ngaphandle koko, kufuneka uqwalasele iindleko zofakelo kunye nokusebenza, njengokuba kukho iifizi zoqeqesho ezongezelelweyo, nokuba uqeshe abasebenzi, njl njl. Oko kukunceda ukuba ukhethe umthengisi we-laser ofanelekileyo kunye neentlobo zoomatshini ngaphakathi kohlahlo lwabiwo-mali.

Amaxabiso omatshini wokusika i-laser ayahluka ngokweentlobo zoomatshini, ulungelelwaniso, kunye neenketho. Sixelele iimfuno zakho kunye nohlahlo lwabiwo-mali, kwaye ingcali yethu ye-laser iya kucebisa umatshini wokusika we-laser ukuba ukhethe.⇨MimoWork Laser

Umthombo weLaser

Xa utyalo-mali kumatshini wokusika we-laser, kufuneka wazi ukuba yeyiphi i-laser umthombo okwaziyo ukusika izinto zakho kunye nokufikelela kwisiphumo esilindelekileyo sokusika. Kukho imithombo emibini eqhelekileyo yelaser:i-fiber laser kunye ne-CO2 laser. I-laser ye-Fiber yenza kakuhle ngokusika kunye nokumakisha kwizinto zetsimbi kunye ne-alloy. I-CO2 laser ikhethekileyo ekusikeni nasekukroleni izinto ezingezizo ezentsimbi. Ngenxa yokusetyenziswa ngokubanzi kwe-CO2 lasers ukusuka kwinqanaba loshishino ukuya kwinqanaba lokusetyenziswa kwasekhaya kwansuku zonke, iyakwazi kwaye kulula ukuyisebenzisa. Xoxa ngemathiriyeli yakho kunye nengcali yethu yelaser, kwaye emva koko umisele umthombo welaser ofanelekileyo.

Uqwalaselo lomatshini

Emva kokumisela umthombo we-laser, kufuneka uxoxe ngeemfuno zakho ezithile zokusika izinto ezifana nesantya sokusika, umthamo wemveliso, ukuchaneka kokusika, kunye neempawu zezinto eziphathekayo kunye nengcali yethu ye-laser. Oko kumisela ukuba yeyiphi i-laser ulungelelwaniso kunye nokhetho olufanelekileyo kwaye inokufikelela kwisiphumo esilungileyo sokusika. Umzekelo, ukuba uneemfuno eziphezulu zemveliso yemihla ngemihla, isantya sokusika kunye nokusebenza kakuhle kuya kuba yingqwalasela yakho yokuqala. Iintloko ezininzi ze-laser, i-autofeeding kunye ne-conveyor systems, kunye ne-software ye-auto-nesting inokuphucula ukusebenza kwakho kwemveliso. Ukuba uxakeke kukusika ngokuchanekileyo, mhlawumbi i-servo motor kunye netyhubhu yentsimbi ye-laser ifaneleke ngakumbi kuwe.

Indawo yokusebenzela

Indawo yokusebenza yinto ebalulekileyo ekukhetheni oomatshini. Ngesiqhelo, ababoneleli ngoomatshini belaser babuza malunga nolwazi lwakho lwemathiriyeli, ngakumbi ubungakanani bezinto eziphathekayo, ubukhulu, kunye nobukhulu bepateni. Oko kumisela ifomathi yetafile yokusebenza. Kwaye ingcaphephe ye-laser iya kuhlalutya ubungakanani bepateni yakho kunye ne-contour yemilo ngokuxoxa nawe, ukufumana eyona ndlela ilungileyo yokutya ukuze ihambelane netafile yokusebenza. Sinobungakanani obuqhelekileyo bokusebenza kumatshini wokusika i-laser, onokuhlangabezana neemfuno zabathengi abaninzi, kodwa ukuba unemathiriyeli ekhethekileyo kunye neemfuno zokusika, nceda usigcine usazi, ingcali yethu ye-laser inobuchule kwaye inamava okusingatha inkxalabo yakho.

Ubugcisa

Umatshini wakho

| Ubungakanani bokusebenza komatshini (W * L) |

| •600mm * 400mm |

| •1000mm * 600mm |

| •1300mm * 900mm |

| •1300mm * 2500mm |

| •1600mm * 1000mm |

| •1600mm * 1200mm |

| •1600mm * 3000mm |

| •1600mm * 10000mm |

| •1800mm * 1400mm |

| •2500mm * 3000mm |

| •3200mm * 1400mm |

Ukuba uneeMfuno eziKhethekileyo zobungakanani bomatshini, Thetha nathi!

Umenzi womatshini

Kulungile, unolwazi lwakho lwempahla, iimfuno zokusika, kunye neentlobo zomatshini ezisisiseko, inyathelo elilandelayo kufuneka ukhangele umenzi womatshini wokusika we-laser othembekileyo. Unokukhangela kwiGoogle, kunye neYouTube, okanye uqhagamshelane nabahlobo bakho okanye amaqabane, nokuba yeyiphi na indlela, ukuthembeka kunye nokunyaniseka kwababoneleli ngomatshini bahlala bebaluleke kakhulu. Zama ukubathumelela i-imeyile, okanye uncokole nengcali yabo yelaser kuWhatsApp, ukufunda ngakumbi malunga nokuveliswa koomatshini, apho umzi-mveliso ulele khona, indlela yokuqeqesha kunye nokukhokela emva kokufumana umatshini, kunye nezinye ezinjalo. Abanye abathengi baye bayalela umatshini kwiifektri ezincinci okanye iiplatifomu zomntu wesithathu ngenxa yexabiso eliphantsi, nangona kunjalo, xa umatshini uneengxaki ezithile, awusoze ufumane naluphi na uncedo kunye nenkxaso, eya kulibazisa imveliso yakho kunye nokuchitha ixesha.

I-MimoWork Laser ithi: Sihlala sibeka iimfuno zomthengi kwaye sisebenzise amava kuqala. Oko ufumanayo akukhona nje umatshini we-laser omhle kwaye oqinileyo, kodwa kunye neseti yenkonzo epheleleyo kunye nenkxaso ukusuka kufakelo, uqeqesho ukuya ekusebenzeni.

① Fumana uMvelisi othembekileyo

Ukhangelo lukaGoogle kunye noYouTube, okanye undwendwele ireferensi yendawo

② Jonga kwiWebhusayithi okanye kuYouTube

Jonga iintlobo zoomatshini kunye nolwazi lwenkampani

③ Dibana neNgcali yeLaser

Thumela i-imeyile okanye uncokole nge-WhatsApp

⑥ Faka iodolo

Misela ixesha lokuhlawula

⑤ Misela ezoThutho

ngenqanawa okanye imithwalo emoyeni

④ Intlanganiso ye-Intanethi

Xoxa ngowona matshini we-laser soultion

Malunga nothethwano kunye neNtlanganiso

> Loluphi ulwazi ekufuneka ulunikeze?

> Iinkcukacha zethu zoqhagamshelwano

UKUSEBENZA

7. Indlela yokusebenzisa iLaser Cutting Machine?

I-Laser Cutting Machine ngumatshini ohlakaniphile kunye ngokuzenzekelayo, kunye nenkxaso yenkqubo ye-CNC kunye nesofthiwe yokusika i-laser, umatshini we-laser unokujongana nemizobo enzima kwaye ucwangcise indlela yokusika ngokufanelekileyo ngokuzenzekelayo. Udinga nje ukungenisa ifayile yokusika kwi-laser system, khetha okanye usethe i-laser cutting parameters njengesantya kunye namandla, kwaye ucinezele iqhosha lokuqala. I-laser cutter iya kugqiba yonke inkqubo yokusika. Ndiyabulela kumgca wokusika ogqibeleleyo kunye nomgca ogudileyo kunye nomgangatho ococekileyo, akudingeki ukuba unciphise okanye upholise iziqwenga ezigqityiweyo. Inkqubo yokusika i-laser ikhawuleza kwaye ukusebenza kulula kwaye kunobungane kubaqalayo.

▶ Umzekelo 1: Ilaphu lokusika iLaser

Inyathelo 1. Beka i-Roll Fabric kwi-Auto-Feeder

Lungiselela ilaphu:Beka ilaphu le-rolling kwinkqubo yokutya okuzenzekelayo, gcina ilaphu lithe tyaba kwaye umphetho ucocekile, kwaye uqalise i-auto feeder, beka ilaphu lokuqengqeleka kwitafile yokuguqula.

Umatshini weLaser:Khetha umatshini wokusika welaphu welaphu kunye ne-auto feeder kunye netafile yokuhambisa. Indawo yokusebenza yomatshini kufuneka ihambelane nefomathi yelaphu.

▶

Inyathelo 2. Ngenisa iFayile yokuSika kwaye usete iiParamitha zeLaser

Ifayile yoyilo:Ngenisa ifayile yokusika kwi-software yokusika i-laser.

Seta iiParameters:Ngokubanzi, kufuneka usete amandla e-laser kunye nesantya selaser ngokobunzima bezinto eziphathekayo, ubuninzi, kunye neemfuno zokusika ukuchaneka. Izinto ezinqabileyo zifuna amandla aphantsi, unokuvavanya isantya se-laser ukuze ufumane isiphumo sokusika esifanelekileyo.

▶

Inyathelo 3. Qalisa iLaser Cutting Fabric

Ukusika kweLaser:Iyafumaneka kwiintloko zokusika i-laser ezininzi, ungakhetha iintloko ezimbini ze-laser kwi-gantry enye, okanye iintloko ezimbini ze-laser kwi-gantry ezimbini ezizimeleyo. Oko kwahlukile kwimveliso yokusika i-laser. Kufuneka uxoxe nengcali yethu ye-laser malunga nepateni yakho yokusika.

▶ Umzekelo 2: ILaser Cutting Printed Acrylic

Inyathelo 1. Beka i-Acrylic Sheet kwi-Working Table

Beka iMaterial:Beka i-acrylic eprintiweyo kwitheyibhile yokusebenza, i-laser cutting acrylic, sasebenzisa itafile yokusika i-knife strip enokuthi ithintele ukuba izinto zitshiswe.

Umatshini weLaser:Sicebisa ukusebenzisa i-acrylic laser engraver 13090 okanye i-laser cutter enkulu 130250 ukusika i-acrylic. Ngenxa yepateni eprintiweyo, ikhamera yeCCD iyadingeka ukuqinisekisa ukusika ngokuchanekileyo.

▶

Inyathelo 2. Ngenisa iFayile yokuSika kwaye usete iiParamitha zeLaser

Ifayile yoyilo:Ngenisa ifayile yokusika kwisofthiwe yokuqaphela ikhamera.

Seta iiParameters:In ngokubanzi, kufuneka usete amandla e-laser kunye nesantya selaser ngokobuninzi bezinto eziphathekayo, ubuninzi, kunye neemfuno zokusika ukuchaneka. Izinto ezinqabileyo zifuna amandla aphantsi, unokuvavanya isantya se-laser ukuze ufumane isiphumo sokusika esifanelekileyo.

▶

INyathelo 3. Ikhamera yeCCD Nakana iPateni eprintiweyo

Uqwalaselo lwekhamera:Kwimathiriyeli eprintiweyo efana ne-acrylic eprintiweyo okanye ilaphu le-sublimation, inkqubo yokuqaphela ikhamera iyafuneka ukuze iqaphele kwaye ibeke ipateni, kwaye iyalele intloko yelaser ukuba isike ecaleni kwekhonta elungileyo.

Inyathelo lesi-4. Qalisa ukusika iLaser kunye nePateni yeContour

Ukusika iLaser:Bnjengoko ibekwe kwindawo yekhamera, intloko yokusika i-laser ifumana indawo efanelekileyo kwaye iqala ukusika ecaleni kwendlela ye-contour. Yonke inkqubo yokusika izenzekelayo kwaye ihambelana.

▶ Iingcebiso kunye namaqhinga xa usika iLaser

✦ Ukukhethwa kwezinto:

Ukufikelela kwisiphumo esilungileyo sokusika i-laser, kufuneka uphathe izinto kwangaphambili. Ukugcina imathiriyeli ithe tyaba kwaye icocekile iyimfuneko ukwenzela ukuba ubude be-laser cutting focal bufana nokugcina isiphumo sokusika sihlala sisikhulu. Kukho iintlobo ezininzi ezahlukeneyoizixhoboenokunqunyulwa i-laser kwaye ikrolwe, kwaye iindlela zonyango zangaphambili zahlukile, ukuba umtsha kule nto, ukuthetha nengcali yethu ye-laser lolona khetho lungcono.

✦Vavanya kuqala:

Yenza uvavanyo lwelaser usebenzisa iisampulu ezithile, ngokuseta amandla ahlukeneyo e-laser, isantya selaser ukuze ufumane iiparamitha zelaser ezifanelekileyo, ukuphumela kwisiphumo esigqibeleleyo sokusika ukuhlangabezana neemfuno zakho.

✦Ukungenisa umoya:

Izinto zokusika iLaser zinokuvelisa umsi kunye nerhasi eyinkunkuma, ngoko ke kufuneka inkqubo yokungenisa umoya eyenziwe kakuhle. Ngokuqhelekileyo sixhobisa i-fan exhaust ngokwendawo yokusebenza, ubungakanani bomatshini, kunye nezinto zokusika.

✦ uKhuseleko lweMveliso

Kwezinye izinto ezikhethekileyo ezifana nezixhobo ezidibeneyo okanye izinto zeplastiki, sicebisa abathengi ukuba baxhobiseisixhobo sokukhupha umsikumatshini wokusika we-laser. Oko kunokwenza indawo yokusebenza icoceke kwaye ikhuseleke ngakumbi.

✦ Fumana uJoliso lweLaser:

Qinisekisa ukuba i-laser beam igxininiswe ngokufanelekileyo kumphezulu wezinto eziphathekayo. Unokusebenzisa ezi ndlela zovavanyo zilandelayo zokufumana ubude obuchanekileyo be-laser, kwaye ulungelelanise umgama ukusuka kwintloko ye-laser ukuya kumphezulu wezinto ezibonakalayo ngaphakathi koluhlu oluthile olujikeleze ubude bogxininiso, ukufikelela kweyona nto ilungileyo yokusika kunye nesiphumo sokukrola. Kukho umahluko phakathi kokusika kwe-laser kunye ne-laser engraving. Ukufumana iinkcukacha malunga nendlela yokufumana ubude obuchanekileyo, nceda ujonge ividiyo >>

IsiFundo seVidiyo: Ungakufumana njani ukuGqalisela okuLungileyo?

▶ Yinyamekele iChiller yakho yamanzi

Isibandisi samanzi kufuneka sisetyenziswe kwindawo engena umoya nepholileyo. Kwaye itanki yamanzi kufuneka icocwe rhoqo kwaye amanzi kufuneka atshintshwe rhoqo kwiinyanga ezi-3. Ebusika, ukongeza i-antifreeze kwi-chiller yamanzi kuyimfuneko ukukhusela iqhwa. Funda ngakumbi malunga nendlela yokugcina ingqele yamanzi ebusika, nceda ujonge iphepha:Amanyathelo obungqina bokukhenkceza kwi-Laser Cutter ebusika

▶ Coca iLens yokuJolisa kunye nezipili

Xa kusikwa i-laser kwaye kukrolwa ezinye izinto, ezinye iziqhumiso, inkunkuma, kunye neresin ziya kuveliswa kwaye zishiywe kwizipili kunye nelensi. Inkunkuma eqokelelweyo ivelisa ubushushu bokonakalisa ilensi kunye nezipili, kwaye inefuthe kwimveliso yamandla e-laser. Ngoko ukucoca i-lens ekugxilwe kuyo kunye nezibuko kuyimfuneko. Gxuma i-cotton swab emanzini okanye utywala ukuze usule umphezulu we-lens, khumbula ukuba ungawuchukumisi umphezulu ngezandla zakho. Kukho isikhokelo sevidiyo malunga naloo nto, khangela oku >>

▶ Gcina Itafile Yokusebenza icocekile

Ukugcina itafile yokusebenza icocekile kubalulekile ukubonelela indawo yokusebenza ecocekileyo kunye nesicaba kwizinto kunye nentloko yokusika i-laser. I-resin kunye nentsalela ayigcini nje ukungcolisa izinto eziphathekayo, kodwa ichaphazela umphumo wokusika. Ngaphambi kokucoca itafile yokusebenza, kufuneka ucime umatshini. Emva koko sebenzisa i-vacuum cleaner ukususa uthuli kunye ne-debris eseleyo kwitafile yokusebenza kwaye ushiye kwibhokisi yokuqokelela inkunkuma. Kwaye uhlambulule itafile yokusebenza kunye nomzila kunye nethawula yekotoni ethotywe ngumcoci. Ukulinda itafile yokusebenza ukuba yome, kwaye iplagi kumandla.

▶ Coca Ibhokisi Yokuqokelela Uthuli

Coca ibhokisi yokuqokelela uthuli yonke imihla. Olunye udoti kunye neentsalela eziveliswa kwizinto zokusika i-laser ziwela kwibhokisi yokuqokelela uthuli. Kufuneka ucoce ibhokisi amaxesha amaninzi emini ukuba umthamo wemveliso mkhulu.

• Qinisekisa oko ngamaxesha athileukhuseleko interlockszisebenza ngokufanelekileyo. Qinisekisa iiqhosha lokumisa likaxakeka, ukukhanya komqondisozibaleka kakuhle.

•Faka umatshini phantsi kwesikhokelo se-laser technician.Ungaze uvule umatshini wakho wokusika i-laser de udityaniswe ngokupheleleyo kwaye zonke iikhava zisendaweni.

•Musa ukusebenzisa i-laser cutter kunye nomkroli kufutshane nawo nawuphi na umthombo wobushushu onokwenzeka.Ngalo lonke ixesha gcina indawo ejikeleze isisiki ingenankunkuma, i-clutter, kunye nezinto ezinokutsha.

• Ungazami ukulungisa umatshini wokusika we-laser wedwa -fumana uncedo lweengcaliukusuka kwigcisa lelaser.

•Sebenzisa imathiriyeli yokhuseleko lwe-laser. Ezinye izinto ezikroliweyo, eziphawulweyo, okanye ezisikwe ngelaser zinokuvelisa imisi eyityhefu neyonakalisayo. Ukuba awuqinisekanga, nceda uqhagamshelane nengcali yakho ye-laser.

•UNGAZE usebenze inkqubo ungajongwanga. Qinisekisa ukuba umatshini welaser osebenza phantsi kweliso lomntu.

• AInto yokucima umliloKufuneka ixhonywe eludongeni kufutshane neLaser Cutter.

• Emva kokusika ezinye izinto zokuqhuba ubushushu, wenakufuneka i-tweezers okanye iiglavu ezishinyeneyo ukuze uthabathe izinto.

• Kwezinye imathiriyeli ezifana neplastiki, ukusika ngelaser kunokuvelisa umsi omninzi kunye nothuli olungavumeliyo indawo osebenzela kuyo. Emva koko aisixhobo sokukhupha umsilolona khetho lwakho lungcono, olunokuthi lufunxe kwaye luhlambulule inkunkuma, ukuqinisekisa ukuba indawo yokusebenza icocekile kwaye ikhuselekile.

•Iiglasi zokhuseleko zeLaserziye zayilwa ngokukhethekileyo iilensi ezifakwe tinted ukuze zifunxe ukukhanya kwelaser kwaye zikuthintele ukuba kungadluleli kwamehlo omntu. Iiglasi kufuneka zihambelane nodidi lwelaser (kunye nobude bobude) oyisebenzisayo. Bakwathanda ukuba nemibala eyahlukeneyo ngokobude bewavelength abayifunxayo: eluhlaza okwesibhakabhaka okanye eluhlaza kwii-laser ze-diode, ezingwevu kwii-CO2 lasers, kunye nokukhanya okuluhlaza kwiilaser zefiber.

FAQ

• Yimalini umatshini wokusika i-laser?

Abasiki belaser be-CO2 abasisiseko bahluka kwixabiso ukusuka ngaphantsi kwe-2,000 yeedola ukuya ngaphezulu kwe-200,000 yeedola. Umahluko wamaxabiso mkhulu kakhulu xa kuziwa kuhlengahlengiso olwahlukileyo lwe-CO2 laser cutters. Ukuqonda iindleko zomatshini we-laser, kufuneka ucinge ngaphezu kwethegi yexabiso lokuqala. Kuya kufuneka kwakhona uqwalasele iindleko ezipheleleyo zokuba ngumatshini welaser kubo bonke ubomi bawo, ukuvavanya ngcono ukuba kufanelekile ukutyala imali kwisiqwenga sesixhobo selaser. Iinkcukacha malunga namaxabiso omatshini wokusika i-laser ukujonga iphepha:Uxabisa malini umatshini weLaser?

• Usebenza njani umatshini wokusika i-laser?

I-laser beam iqala ukusuka kumthombo we-laser, kwaye iqondiswe kwaye igxininiswe kwizibuko kunye ne-lens egxininise kwintloko ye-laser, emva koko idutyulwe kwizinto eziphathekayo. Inkqubo ye-CNC ilawula isizukulwana se-laser beam, amandla kunye ne-pulse ye-laser, kunye nendlela yokusika intloko ye-laser. Idityaniswe ne-air blower, i-fan exhaust, isixhobo sokunyakaza kunye netafile yokusebenza, inkqubo yokusika i-laser esisiseko inokugqitywa kakuhle.

• Yeyiphi igesi esetyenziswa kumatshini wokusika i-laser?

Kukho iinxalenye ezimbini ezifuna igesi: i-resonator kunye nentloko yokusika i-laser. Kwi-resonator, igesi ebandakanya ukucoceka okuphezulu (ibanga lesi-5 okanye elingcono) i-CO2, i-nitrogen, kunye ne-helium kufuneka ivelise i-laser beam. Kodwa ngokuqhelekileyo, awudingi ukutshintsha ezi gesi. Kwintloko yokusika, i-nitrogen okanye i-oksijini incedisa igesi iyadingeka ukuze incede ukukhusela izinto eziza kucutshungulwa kunye nokuphucula i-laser beam ukufikelela kwisiphumo esilungileyo sokusika.

• Nguwuphi uMahluko: Umsiki weLaser VS Umsiki weLaser?

Malunga neMimoWork Laser

I-Mimowork yimveliso yelaser ejolise kwiziphumo, ese-Shanghai nase-Dongguan China, izisa iminyaka engama-20 yobuchwephesha bokusebenza obunzulu ukuvelisa iinkqubo ze-laser kunye nokubonelela ngezisombululo ezibanzi zokusetyenzwa kunye nemveliso kwii-SME (amashishini amancinci naphakathi) kuluhlu olubanzi lwamashishini.

Amava ethu atyebileyo ezisombululo zelaser zokwenziwa kwesinyithi kunye nezinto ezingezizo ezentsimbi zimiliselwe nzulu kwihlabathi liphelaisibhengezo, izithuthi kunye nophapho, izixhobo zentsimbi, izicelo zedayi sublimation, ilaphu kunye nempahlaamashishini.

Kunokuba unikeze isisombululo esingaqinisekanga esifuna ukuthengwa kubavelisi abangafanelanga, iMimoWork ilawula yonke inxalenye yekhonkco lemveliso ukuqinisekisa ukuba iimveliso zethu zisebenza kakuhle rhoqo.

Ngokukhawuleza Funda ngakumbi:

Ngena kwiLizwe lobuGcisa lomatshini wokusika iLaser,

Thetha ngeNgcali yethu yeLaser!

Ixesha lokuposa: May-27-2024